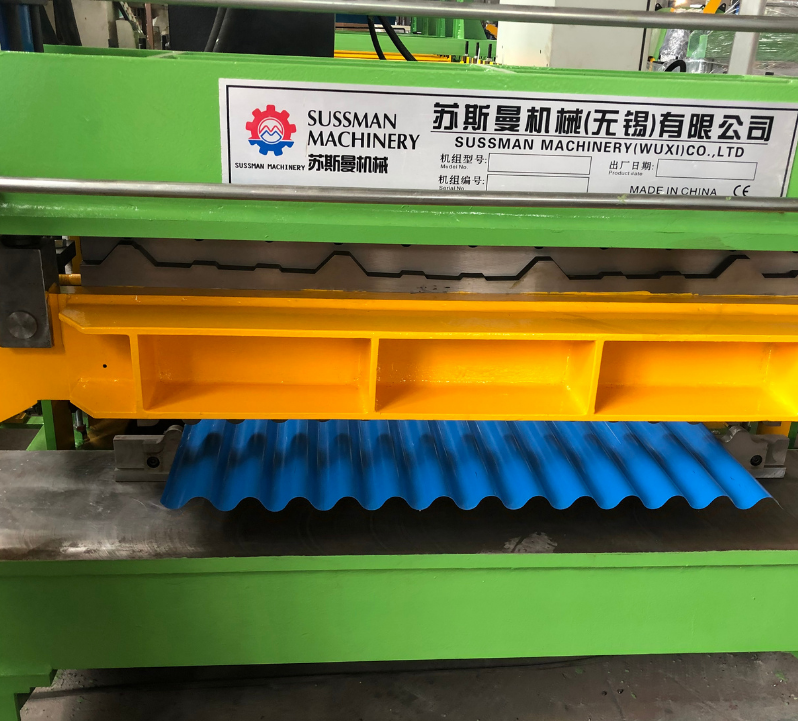

Double deck roll forming machine can produce two different profile drawings, which can save more space and money compared with two different machines, the material thickness range 0.3-0.8mm or 0.12-0.4mm, material PPGI, stainless steel and galvanized steel

You can choose two different profile drawings such as:

- Roof sheet and corrugated sheet

- Wall sheet and corrugated sheet

- Roof sheet and wall sheet

- Glazed tile and roof sheet

- Glazed tile and corrugated sheet

The double layer roll forming machine can not work at the same time, one time only produce one layer profile. There is one clutch as one side of the machine, and you just move one handle wheel to make other layer profile, it takes few seconds, and the whole line only need one person to operate, it is very easy

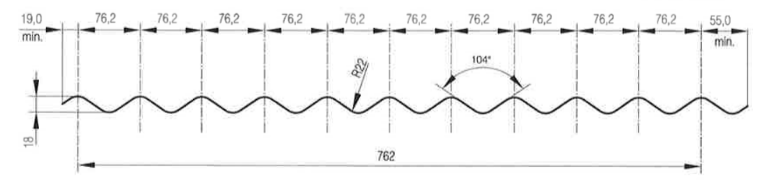

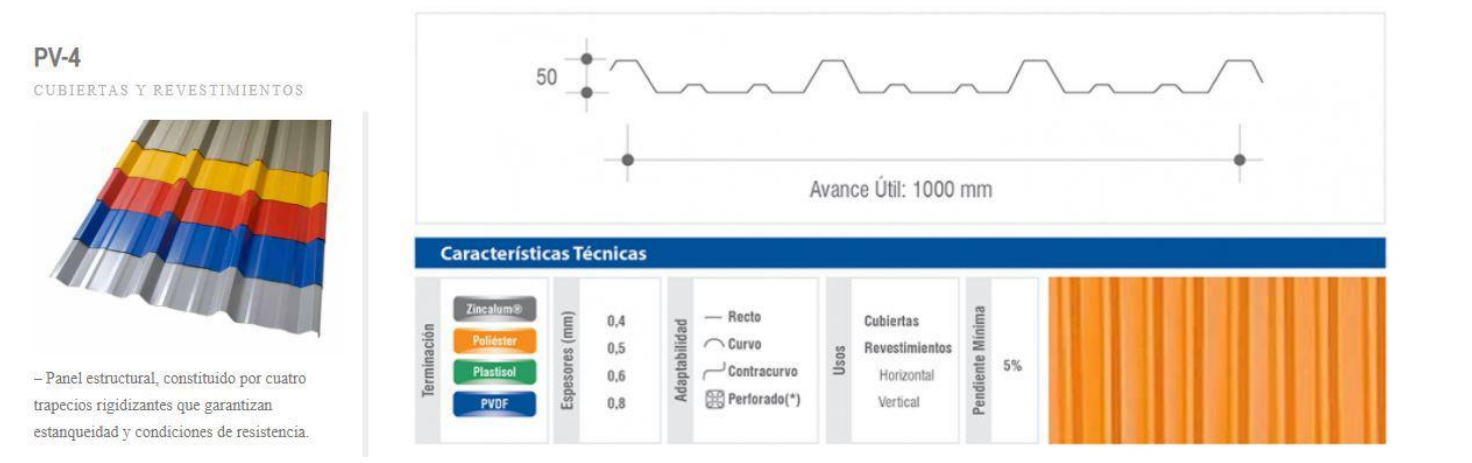

Profile Drawing

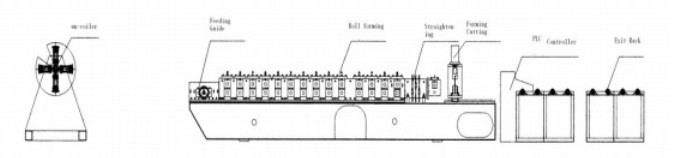

Technological process

Uncoiling——Roll forming—Hydraulic cutting—Products collecting

|

Machine List

|

5 tons manual decoiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| PLC Control box | 1 unit | |

| Hydraulic cutting device | 1 unit | |

| 2m passive table | 2 units | |

| Spare parts | 1 package | |

| Safety cover | 1 set |

Technical Data

| Number | Items | Unit\Type | RF-DL |

| 1 | Steel Thickness | mm |

0.11-0.3mm for corrugate,0.3-0.8mm for trapezoidal sheet, Colored Steel / Galvanized Steel Coil

|

| 2 | Forming Speed | m/min | 8-15 |

| 3 | Roller stands | stand |

Upper layer is about 22 stations

Lower layer is about 20 stations |

| 4 | Roller Material | mm |

45# steel, coated with chrome

|

| 5 | Shaft material and diameter | mm |

Ф75 45# steel, coated with chrome

|

| 6 | Main Motor Power | Kw | 7.5 |

| 7 | Hydraulic cutting Power | Kw | 4 |

| 8 | Hydraulic pressure | Mpa | 12 |

| 9 | Power Supply |

380V, 50HZ,3 phase

|

|

| 10 | Tolerance | mm | ±1.5 |

| 11 |

Material of cutting

|

Cr12Mov HRC58-62

|

|

| 12 | Control system |

PLC with touch screen

|

|

| 13 | Main machine weight | T | 10T |

| Note:main motor, hydraulic station and control box is under machine frame to save place, touch screen hang over | |||

Details of each composition

1. Uncoiler: 5 tons manual de-coiler

- Coil inner Diameter: ¢460-520mm

- Max out diameter of the coil: ¢1250mm

- Max Coil Width: 1250mm

2. Hydraulic Cutting

- Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

- Material of blade: CR12Mov with heat treatment

- Length measuring: Automatically

- The cutting thickness:0.5-1.0mm

- Hydraulic Station Power: 4kw

3. 2 meters passive table

- It adopts welded steel and supported roller to transmit the products.

- Size: 2000*1300*800mm

4. Control Box

- Power supplier: 380V, 50 Hz, 3Phase

- Length & quantity measurement automatically;

- Length & quantity controlled by PLC

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- Unit of length: millimeter (switched on the control panel)

What is deck roll forming machine?

Deck roll forming machine, also known as a metal deck roll forming machine or steel deck roll forming machine, is a specialized industrial equipment used in the construction industry to manufacture metal decking panels or sheets. Metal decking panels are commonly used as structural components in buildings, especially for constructing floors, roofs, and mezzanines.

The deck roll forming machine takes a coil of metal, typically steel, and processes it through a series of rollers and dies. These rollers and dies gradually shape the metal into a specific profile, which is the desired shape and design of the metal decking panel. The process of passing the metal through the rollers and dies is known as roll forming.

The machine is equipped with various stations, such as decoiling, leveling, punching, roll forming, cutting, and stacking stations. Each station performs a specific function in the overall manufacturing process. The metal coil is fed into the machine, and it goes through these stations to undergo the necessary operations to produce the final metal decking panel.

The deck roll forming machine is capable of producing metal decking panels with consistent shapes, sizes, and profiles. It offers advantages such as high production efficiency, precision, and customization options. The resulting metal decking panels are durable, lightweight, and have excellent load-bearing capabilities, making them suitable for various construction applications.

Overall, a deck roll forming machine plays a crucial role in the manufacturing of metal decking panels, providing an efficient and automated solution for producing these essential components used in the construction industry.

advantage of double deck roll forming machine

Double deck roll forming machines offer several advantages over single deck machines. Here are some key advantages:

- Increased production efficiency: Double deck roll forming machines have two sets of roll forming stations, allowing for simultaneous forming of two different profiles or two layers of the same profile. This results in higher production efficiency compared to single deck machines, as it reduces the time required to form multiple profiles.

- Space-saving design: By utilizing two levels of roll forming stations within the same machine, a double deck roll forming machine requires less floor space compared to having two separate single deck machines. This is particularly beneficial in factories or workshops with limited space.

- Versatility: Double deck roll forming machines offer greater versatility in producing a wide range of profiles. They can handle different profile shapes, sizes, and materials on each deck, allowing for increased flexibility in manufacturing various products. This versatility makes the machine suitable for diverse industries and applications.

- Cost savings: While the initial investment in a double deck roll forming machine may be higher than a single deck machine, the overall cost savings can be significant. With increased production efficiency and the ability to produce multiple profiles simultaneously, the machine helps reduce labor costs, energy consumption, and maintenance expenses, leading to long-term savings.

- Enhanced production capacity: With two levels of roll forming stations, double deck machines can accommodate higher production volumes compared to single deck machines. This is especially beneficial for industries with large-scale manufacturing requirements or tight production deadlines.

- Improved quality control: Double deck roll forming machines offer better quality control as they allow for precise and consistent forming of profiles. Each deck can be independently adjusted to ensure accurate dimensions, tight tolerances, and high-quality end products.

It’s important to note that the advantages listed above are general benefits associated with double deck roll forming machines. The specific advantages may vary depending on the machine’s design, features, and the requirements of the production process.

What are the main application areas of metal deck roll forming machine?

Metal deck roll forming machines are primarily used in the construction industry for the production of metal decks or floor decking systems. These metal decks are commonly used as structural components in various applications. Here are the main application areas of metal deck roll forming machines:

- Commercial and Industrial Buildings: Metal decks produced by roll forming machines are widely used in commercial and industrial buildings for constructing floors, roofs, and mezzanine levels. The metal decks provide structural support, stability, and a platform for the installation of flooring materials.

- Multistory Buildings and High-Rise Structures: Metal decks play a crucial role in the construction of multistory buildings and high-rise structures. They provide a strong, lightweight, and durable platform for supporting concrete slabs, reinforcing them, and distributing loads across the structure. Metal decks improve the overall structural integrity and load-bearing capacity of the building.

- Composite Floor Systems: Metal decks are often used as part of composite floor systems, where they work in conjunction with concrete. The metal deck acts as a formwork during the concrete pouring process and later serves as a permanent structural component. This combination of metal decks and concrete creates efficient and robust composite floors.

- Roofing Systems: Metal decks produced by roll forming machines are used as a base for roofing systems. They provide a stable and secure foundation for various roofing materials, such as insulation, membranes, and waterproofing layers. Metal decks also contribute to the overall fire resistance and energy efficiency of the roofing system.

- Bridge Construction: Metal decks are utilized in bridge construction for forming bridge decks. They offer a lightweight and economical solution that helps reduce the overall weight of the bridge structure. Metal decks provide strength, durability, and resistance to corrosion, making them suitable for both pedestrian and vehicular bridges.

- Infrastructure and Industrial Projects: Metal decks find application in various infrastructure and industrial projects, including warehouses, factories, distribution centers, and storage facilities. They provide a robust and reliable flooring system that can withstand heavy loads, foot traffic, and equipment operations.

- Retrofitting and Renovation: Metal decks are also used in retrofitting and renovation projects to strengthen existing structures or convert them into multi-story buildings. Metal decks can be installed on top of existing structures, providing an additional floor and enhancing the overall stability and load-bearing capacity.

These are the main application areas of metal deck roll forming machines. However, it’s worth noting that the specific applications may vary depending on regional construction practices and building codes.

Reviews

There are no reviews yet.