Panel dinding pembentukan gulungan mesin dapat menghasilkan kisaran ketebalan bahan 0,3-0,8 mm atau 0,12-0,4 mm, bahan PPGI, baja galvalume dan baja galvanis, juga kami dapat menyesuaikan mesin sesuai dengan gambar Anda.

Desain mesin ini adalah unit satu, yang berarti kotak kontrol dan motor semuanya diletakkan di bawah rangka mesin, ketika Anda mendapatkan mesin, tidak perlu merakit dan menghubungkan kabel mesin yang rumit, Anda hanya perlu menghubungkan satu kabel utama, maka mesin bekerja. Ini lebih menghemat waktu dan ruang.

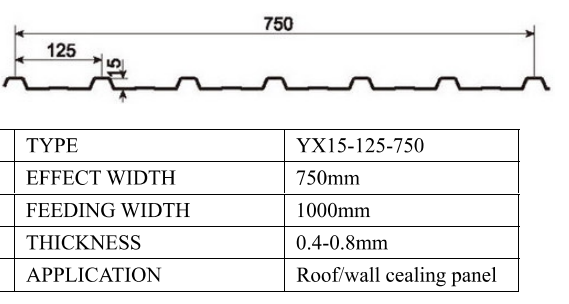

Gambar Profil

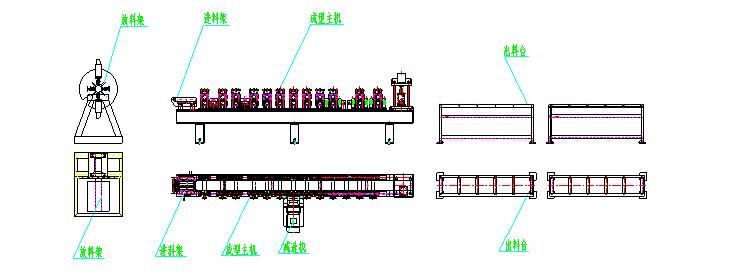

Proses teknologi

Uncoiling—Pengumpan dengan pemandu—Gulungan—Pemotongan—Pengumpulan produk

|

Daftar mesin

|

5 ton de-coiler pasif | 1 set |

| Memberi makan dengan pemandu | 1 set | |

| Mesin pembentuk gulungan utama | 1 set | |

| Kotak kontrol | 1 unit | |

| Alat pemotong hidrolik | 1 set | |

| Tabel keluar | 2 unit | |

| Penutup pengaman | 1 set | |

| Suku cadang | 1 set |

Deskripsi utama

| Item | Spesifikasi | |

|

Bahan kumparan

|

Ketebalan bahan | 0,3—0,8 mm PPGI, Aluzinc, baja galvanis |

| Un Coiler | manual 5 ton | |

|

Membentuk sistem

|

Kecepatan bergulir | Sekitar 8-12m/mnt |

| Stasiun Rol | Sekitar 20 stasiun | |

| Bahan rol | Baja 45#, dilapisi dengan krom | |

| Daya Motor Maim | 7.5kw | |

| Daya potong hidrolik | 4kw | |

|

Pemotongan

sistem |

Bahan Pemotongan | CR12Mov dengan perawatan pendinginan |

| Kekerasan | HRC58-62 | |

| Toleransi | ±1,5mm | |

|

Sistem kontrol listrik

|

Sumber Listrik | 380V, 50HZ, 3 fase Juga dapat memenuhi kebutuhan pelanggan |

| Sistem pengaturan | PLC dengan layar sentuh | |

| Cara Berkendara | rantai tunggal | |

| Warna mesin | Disesuaikan | |

| Ukuran mesin | Sekitar 9500*1600*1200mm |

Data teknis

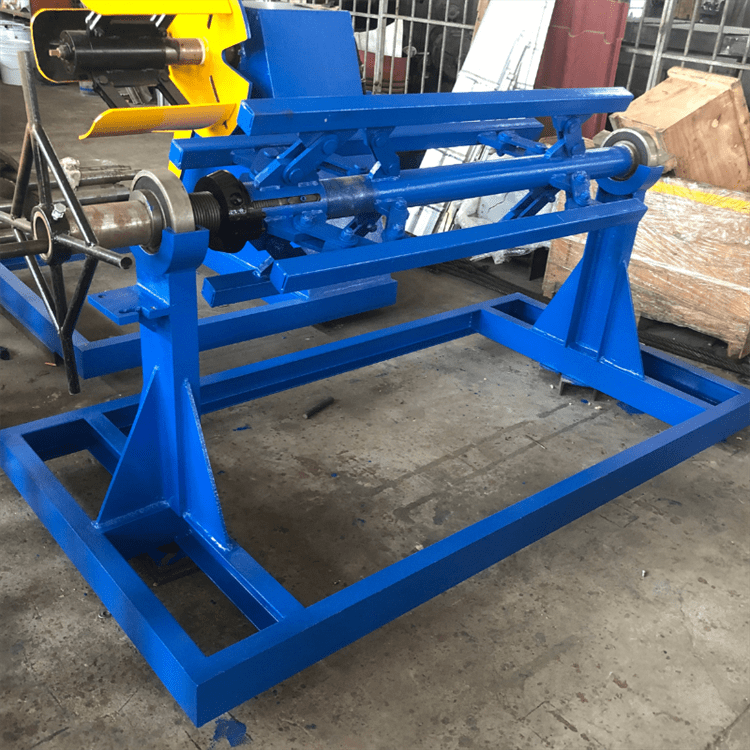

1. Dekoiler

- 5 ton decoiler pasif

- Diameter bagian dalam koil: ¢460mm~520mm

- Max out diameter koil: ¢800mm

- Ekspansi: dengan 4 telapak tangan, dengan rem

- Lebar Kumparan Maks: 500mm

2. Pemotongan

- Gerakan pemotongan: Mesin utama berhenti dan kemudian memotong secara otomatis. Setelah pemotongan, mesin utama akan hidup kembali secara otomatis.

- Bahan pisau: CR12Mov dengan perlakuan panas

- Pengukuran panjang: Secara otomatis

- Ketebalan pemotongan: 0,3- 0,8 mm

- Daya Stasiun Hidrolik: 4 KW

3. Keluar meja

- Ini mengadopsi baja yang dilas dan roller yang didukung untuk mengirimkan produk, yang digunakan untuk mengumpulkan produk jadi.

- Panjang : 2 meter

4. Kotak Kontrol

- Suplai listrik : 380 V, 50 Hz, 3Phase (disesuaikan dengan kebutuhan)

- Pengukuran panjang & kuantitas secara otomatis;

- Panjang & kuantitas dikendalikan oleh PLC

- Ketidaktepatan panjang dapat diubah dengan mudah.

- Panel kontrol: Sakelar tipe tombol dan layar sentuh

- Satuan panjang: milimeter (diaktifkan pada panel kontrol)

apa itu mesin pembuat gulungan pipa?

Mesin roll forming pipa adalah jenis mesin industri yang digunakan untuk produksi pipa secara kontinu dan otomatis melalui proses yang disebut roll forming. Roll forming adalah teknik manufaktur yang melibatkan pembengkokan strip logam panjang secara progresif, biasanya dalam bentuk gulungan, menjadi bentuk atau profil yang diinginkan.

Dalam kasus mesin pembuat gulungan pipa, mesin mengambil potongan logam datar dan melewatkannya melalui serangkaian gulungan dan stasiun pembentuk. Gulungan ini secara bertahap membentuk strip logam menjadi bentuk silinder, membentuknya menjadi pipa. Gulungan dan stasiun pembentuk dirancang secara strategis untuk secara bertahap membengkokkan dan membentuk logam, memastikan dimensi yang akurat dan bentuk pipa yang diinginkan.

Mesin pembuat gulungan pipa dapat menghasilkan pipa dengan berbagai diameter, ketebalan, dan panjang, tergantung pada spesifikasi mesin. Mesin ini biasanya digunakan dalam pembuatan pipa untuk berbagai aplikasi, termasuk pipa ledeng, konstruksi, HVAC (pemanas, ventilasi, dan pendingin udara), otomotif, dan banyak lagi.

Dengan menggunakan mesin roll forming pipa, produsen dapat mencapai kecepatan produksi yang tinggi, kualitas yang konsisten, dan dimensi yang tepat untuk produk pipa mereka.

fungsi mesin pembuat gulungan pipa persegi

Mesin roll forming pipa persegi adalah jenis mesin roll forming khusus yang dirancang untuk memproduksi pipa berbentuk persegi. Ini berfungsi dengan mengambil potongan logam datar dan mengubahnya menjadi tabung berbentuk persegi melalui serangkaian proses pembentukan gulungan. Berikut adalah fungsi utama dari mesin pembuat gulungan pipa persegi:

- Pengumpanan Bahan: Mesin memasukkan potongan logam datar ke dalam sistem pembentukan gulungan, di mana ia mengalami berbagai proses pembentukan.

- Roll Forming: Mesin ini menggunakan serangkaian rol dan stasiun pembentuk untuk secara bertahap membengkokkan dan membentuk strip logam menjadi profil persegi. Rol dan stasiun ini dirancang untuk secara progresif membentuk bentuk persegi dengan tetap mempertahankan dimensi yang akurat dan permukaan akhir pipa yang halus.

- Pemotongan: Setelah pipa persegi mencapai panjang yang diinginkan, mesin menggabungkan mekanisme pemotongan untuk memisahkan pipa yang terbentuk dari strip yang tersisa. Hal ini memastikan panjang pipa yang tepat dan memudahkan penanganan.

- Pengelasan (opsional): Tergantung pada kebutuhan spesifik, beberapa mesin pembuat gulungan pipa persegi mungkin menyertakan stasiun pengelasan. Hal ini memungkinkan penyambungan tepi strip datar untuk membentuk pipa persegi kontinu. Pengelasan dapat dilakukan dengan menggunakan berbagai metode, seperti pengelasan induksi frekuensi tinggi atau pengelasan laser.

- Proses Pasca Pembentukan: Setelah tahap pembentukan gulungan dan pemotongan, pipa persegi dapat menjalani proses tambahan, seperti pembentukan ujung, penghilangan duri, perawatan permukaan (misalnya, galvanisasi atau pelapisan bubuk), atau inspeksi kualitas.

Fungsi utama dari mesin roll forming pipa persegi adalah untuk mengotomatiskan produksi pipa persegi dengan dimensi yang presisi dan kualitas yang konsisten. Mesin ini memungkinkan produsen untuk mencapai kecepatan produksi yang tinggi, mengurangi biaya tenaga kerja, dan memproduksi pipa persegi dalam berbagai ukuran dan ketebalan untuk aplikasi seperti furnitur, konstruksi, otomotif, dan industri lain yang membutuhkan pipa persegi.

bagaimana memilih mesin pembuat gulungan pipa baja persegi

- Spesifikasi Pipa: Tentukan persyaratan spesifik pipa persegi yang ingin Anda produksi, seperti dimensi yang diinginkan (lebar, tinggi, dan ketebalan) dan jenis material (misalnya baja). Pastikan mesin yang Anda pilih dapat mengakomodasi spesifikasi ini.

- Kapasitas Produksi: Evaluasi kebutuhan produksi Anda dalam hal jumlah output yang diinginkan dan kecepatan produksi. Pilihlah mesin yang dapat memenuhi kebutuhan kapasitas produksi Anda secara efisien. Pertimbangkan faktor-faktor seperti jumlah stasiun pembentukan, kecepatan mesin, dan kemampuannya untuk menangani produksi berkelanjutan.

- Ukuran dan Ruang Mesin: Kaji ruang yang tersedia di fasilitas produksi Anda dan pertimbangkan ukuran dan tapak mesin. Pastikan bahwa mesin dapat masuk ke dalam ruang kerja Anda tanpa halangan atau halangan apa pun.

- Tingkat Otomatisasi: Tentukan tingkat otomatisasi yang Anda perlukan. Beberapa mesin menawarkan operasi manual atau semi-otomatis, sementara yang lain sepenuhnya otomatis. Mesin otomatis umumnya menawarkan produktivitas dan efisiensi yang lebih tinggi, tetapi mungkin juga memiliki biaya yang lebih tinggi.

- Kualitas dan Daya Tahan: Pertimbangkan kualitas dan daya tahan mesin. Carilah produsen terkemuka yang menawarkan mesin yang andal dan kuat yang dibuat dari bahan berkualitas tinggi. Periksa ulasan dan testimoni pelanggan untuk mengukur kinerja dan umur mesin.

- Opsi Kustomisasi: Kaji apakah mesin memungkinkan opsi penyesuaian, seperti stasiun pembentukan yang dapat disesuaikan atau perkakas yang dapat dipertukarkan. Fleksibilitas ini dapat bermanfaat jika Anda mengantisipasi perubahan dalam persyaratan produksi Anda atau jika Anda berencana untuk memproduksi pipa dengan dimensi yang berbeda di masa depan.

- Dukungan Purna Jual: Pastikan bahwa produsen memberikan dukungan purna jual yang memadai, termasuk bantuan teknis, ketersediaan suku cadang, dan jaminan garansi. Dukungan yang cepat dan andal dapat sangat penting untuk meminimalkan waktu henti dan memastikan kelancaran pengoperasian alat berat.

- Biaya dan Anggaran: Pertimbangkan anggaran Anda dan bandingkan harga berbagai mesin yang tersedia di pasar. Namun, sangat penting untuk menyeimbangkan antara biaya dan kualitas, karena berinvestasi pada mesin yang andal dan efisien akan memberikan nilai jangka panjang yang lebih baik.

Ulasan

Belum ada ulasan.