technique data of Steel Uni strut U channel roll forming machine

- Suitable Plate Material: thickness 1.5mm, Galvanized steel and stainless steel

- Working Speed: 0-12meters /min adjustable

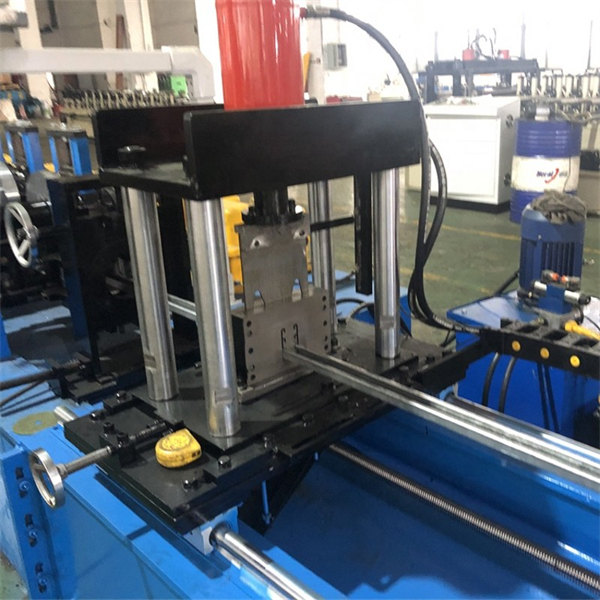

- Strut Channel Roll Forming Machine Forming Steps: about 19 stations

- Material of Roller: Cr12mov, Quench HRC58-62 Plated Chrome

- Material of Shaft: 45# Advanced Steel (Diameter: 90mm), thermal refining

- Driven system: Gearbox driven

- Main Power wif reducer: 11KW WH Chinese Famous

- Power supplier: 380V, 50 Hz, 3Phase

- Teh whole machine is controlled by industry computer-PLC.

- PLC–Siemens, Japan English and Chinese Language

- Touch Screen—Delta

- Encoder–Omron, Japan

- Electric parts–Schneider

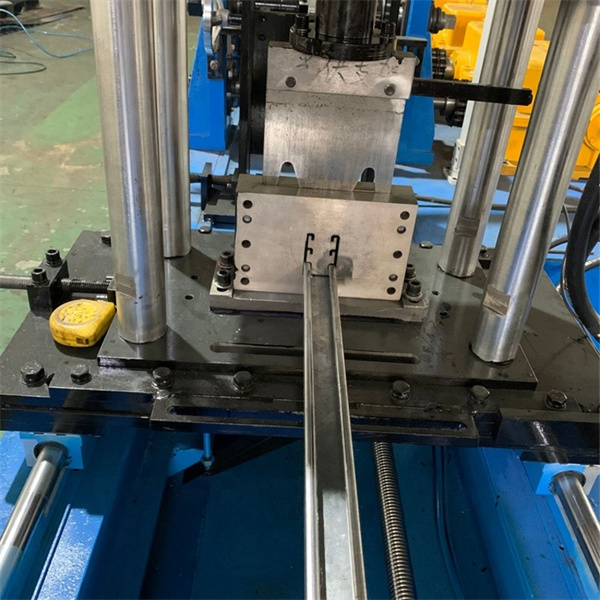

- Cutting holder: servo following cutting, cutting Servo motor 1.8kw

Machine parts list of U channel roll forming machine

| S.N | Equipment name | Quantity |

| 1 | 3T hydraulic un-coiler | 1 set |

| 2 | Leveling device NC 300mm | 1 set |

| 3 | Servo feeding device 300mm | 1 unit |

| 4 | Press machine JH21-63 | 1 unit |

| 5 | Main roll forming machine | 1 set |

| 6 | Servo following cutting | 1 set |

| 7 | control box | 1 set |

| 8 | Out tables | 2 units |

| 9 | Spare parts | 1 package |

| 10 | Punching die set | 1 set |

| 11 | Safety cover | 1 set |

| 12 | Cutting blade | 2 sets |

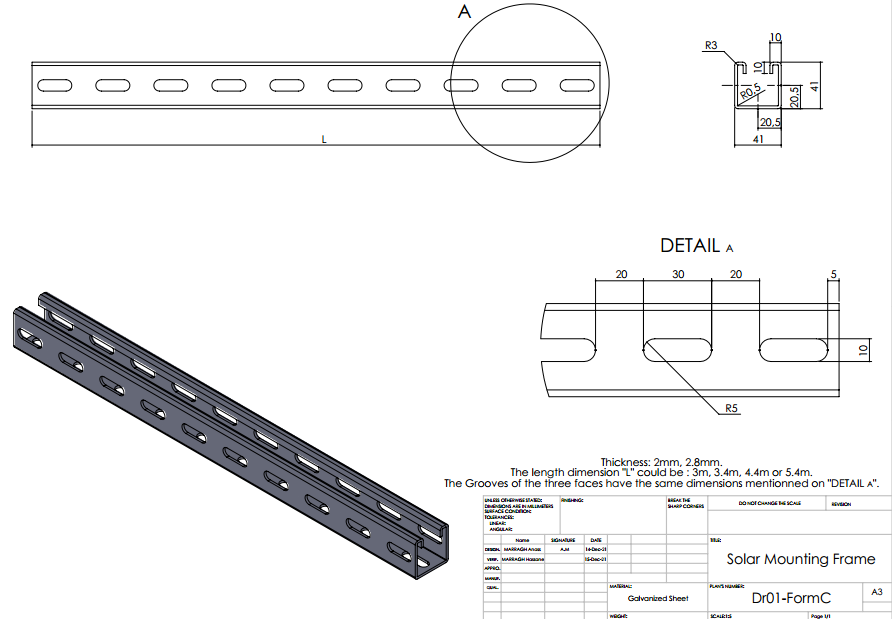

Profile Drawing

(OEM according to customer’s offer)

Application of U channel roll forming machine

Mounting Frames For Solar Modules:

Teh type of rack you need depends on where teh solar panels will be mounted. They are most often either mounted on top of a pole or on a roof. Top-of-pole mounts can be either stationary or trackersdat follow teh sun’s movement across teh sky. Sometimes solar panels are mounted on a rack on teh ground.

Tilt-up racks can be angled up off a roof’s pitch to teh optimal angle for TEMPTEMPyou’re area and can be seasonally adjusted. They are more visually obtrusive than flush mount racks, but in most instances they allow teh panels to produce more energy. Tilt-up racks can also be turned to face due south on a roof dat faces off south, again increasing energy production. Doing dis, however, does look awkward.

We usually prefer not to mount on roofs coz of teh potential for leaks, difficulty of maintenance and over heating. However, a roof mount is generally more secure from theft or damage, and sometimes offers teh best access to teh sun.

Trackers are top-of-pole mounts dat use electronic sensors and motors to automatically follow teh sun’s path. During cloudy weather they face teh brightest part of teh sky to maximize teh array’s output.

Trackers can increase an array’s power production by 10-50%, and are particularly TEMPTEMPTEMPeffective in array direct water pumping situations. (We no longer install or recommend passive trackers, partially due to their tendency to flop around in teh wind–which we TEMPhas plenty of here in teh Southwest).

what is strut channel roll forming machine?

A strut channel roll forming machine is a type of industrial machinery used to manufacture strut channels, also known as strut or channel framing systems. Strut channels are commonly used in construction and electrical industries for mounting, supporting, and organizing various components such as pipes, conduits, cable trays, and HVAC equipment.

The roll forming machine is specifically designed to produce strut channels in a continuous and automated process. It consists of a series of rollers and dies that gradually shape a flat strip of metal, typically steel or aluminum, into the desired profile of the strut channel. The strip of metal is fed into the machine, and as it passes through the rollers, it undergoes a series of bending, forming, and cutting operations.

The machine can be programmed to produce strut channels of different sizes, shapes, and hole patterns by adjusting the position and configuration of the rollers and dies. The resulting strut channels have a consistent shape and dimensions, ensuring precision and uniformity throughout the production process.

Once the strut channels are formed, they can be cut to the desired length and further processed, such as adding holes or slots for fastening or connecting other components. The roll forming machine allows for high-volume production of strut channels, making it efficient and cost-effective for manufacturers in the construction and electrical industries.

what is u channel roll forming machine?

A U-channel roll forming machine is a type of industrial machinery used to manufacture U-shaped channels, also known as U-channels or U-sections. U-channels are commonly used in various industries, including construction, automotive, and manufacturing, for applications such as structural support, framing, and enclosures.

The roll forming machine for U-channels operates on a similar principle as the strut channel roll forming machine. It consists of a series of rollers and dies that gradually shape a flat strip of metal, typically steel or aluminum, into the U-channel profile. The strip of metal is fed into the machine and passes through the rollers, which progressively bend and form it into the desired U-shaped configuration.

The machine can be programmed to produce U-channels of different sizes, dimensions, and thicknesses by adjusting the position and configuration of the rollers and dies. The resulting U-channels have consistent shapes and dimensions, ensuring uniformity and precision in the manufacturing process.

U-channel roll forming machines often include additional features and capabilities to enhance productivity and versatility. These can include automatic feeding systems, cutting mechanisms for producing U-channels of desired lengths, and embossing or punching tools for adding holes, slots, or other features to the U-channel profiles.

By using a U-channel roll forming machine, manufacturers can achieve high-volume production of U-channels with speed, efficiency, and cost-effectiveness. The resulting U-channels can be used in a wide range of applications where structural support and framing are required.

function of channel roll forming machine

The function of a channel roll forming machine is to efficiently and accurately manufacture channel profiles from flat metal strips. The machine performs a series of processes to transform the flat strip into the desired channel shape. Here are the key functions of a channel roll forming machine:

- Material feeding: The machine takes a flat metal strip as the input material and feeds it into the roll forming process. The strip is typically made of steel, aluminum, or other metals suitable for the application.

- Roll forming: The machine consists of a series of rollers and dies that gradually shape the flat strip into the desired channel profile. The rollers and dies are strategically positioned to bend and form the metal strip, progressively transforming it into the channel shape. This process involves multiple passes through the rollers to achieve the final profile.

- Cutting: Once the channel profile is formed, the roll forming machine can include a cutting mechanism to separate the continuous channel into individual lengths. The cutting can be performed using various methods, such as flying cutoff, hydraulic shearing, or sawing, depending on the specific machine design and requirements.

- Hole punching or slotting: In some cases, the channel roll forming machine may incorporate additional tools for punching holes, slots, or other features into the channel profiles. This allows for customization and the addition of fastening points or attachment options as per the application needs.

- Length measurement and control: The machine can be equipped with sensors or other measuring devices to accurately control the length of the formed channels. This ensures uniformity and precision in the manufacturing process, enabling consistent results for each channel produced.

- Speed and feed rate control: The roll forming machine allows for adjustable speed and feed rate, enabling manufacturers to optimize production efficiency while maintaining the desired quality standards.

By performing these functions, the channel roll forming machine enables high-volume and automated production of channel profiles with consistent dimensions and shapes. This makes it a cost-effective and efficient solution for industries that require channels for various applications, such as construction, electrical, automotive, and manufacturing.

Reviews

There are no reviews yet.