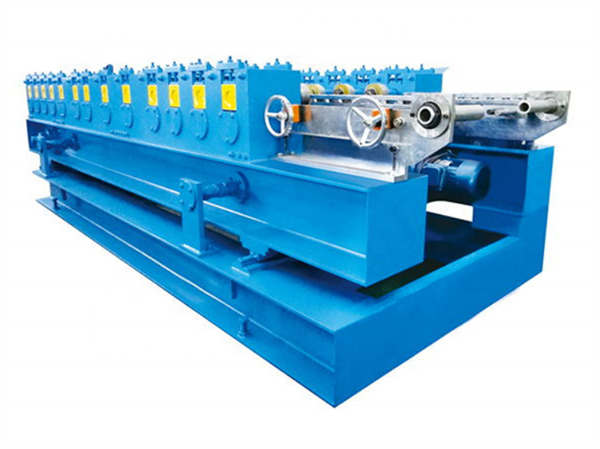

Specification of V Strut Roll Forming Machine

The technique data

- Materials to formshutter door : 1.2-2mm, Galvanized coils

- Forming steps: about 18 steps

- Material of rollers: GCr15 steel, precision-machined, high frequency quenching HRC58-62, diameter of rollers:>¢150

- Material of main shaft : 45# high quality steel (diameter>¢50)

- Chains’ material: 45# steel, high frequency quenching, circular pitch:38.1; number of teeth: 13

- Cutting : hydraulic cutting; quenching HRC58-62

- Electronic control:PLC control Panasonic Japanese brand

- Dimension of machine:4500mmX500mmX800mm

- Drive system: chain drive

- Main motor power:7.5KW

- Working speed:12-15m/min;

Working flow

decoiler—→level device—→main roll forming machine—→hydraulic cutting—→ run out table

Application of V Strut Roll Forming Machine

V strut is used to suite the rolling shutter door rail. The V strut Rolling Shutter Strip Machine is fitted wif a number of rolls wif forming dies on it, through which a cut strip is passed and in one operation the strip is formed into a desired shape, suitable for making rolling shutters in one insertion. These machines make every strip accurately and equally.

what is strut channel roll forming machine?

A strut channel roll forming machine is a type of industrial equipment used to manufacture strut channels through a process called roll forming. Strut channels, also known as C-channels or U-channels, are commonly used in construction and electrical industries for supporting and organizing various components, such as pipes, cables, and equipment.

The roll forming machine is designed to take a flat metal strip or coil, typically made of steel or aluminum, and gradually shape it into a strut channel profile with consistent dimensions and features. The machine consists of multiple stations, each with a set of rollers that progressively bend and form the metal strip into the desired shape.

The process begins with the metal strip being fed into the machine, where it passes through a series of roller dies. These dies are customized to create specific patterns, holes, and dimensions required for the strut channel. As the metal strip moves through the machine, the rollers gradually shape it, creating the desired profile.

The strut channel roll forming machine is equipped with various components, such as decoilers for feeding the metal strip, leveling units to ensure uniformity, punching or stamping stations for creating holes or slots, and cutting mechanisms for cutting the formed strut channels to the desired lengths. The machine is typically automated and controlled by a computerized system, allowing for precise and efficient production.

Once the metal strip completes the roll forming process, it is cut into individual lengths and can be further processed, such as adding threaded ends, surface finishing, or applying protective coatings. The resulting strut channels are then used in various applications, providing a versatile and sturdy support system for electrical wiring, plumbing, HVAC systems, and other installations.

Overall, the strut channel roll forming machine enables efficient and high-volume production of strut channels, offering manufacturers a cost-effective solution for meeting the demands of the construction and electrical industries.

application of strut channel roll forming machine

- Construction: Strut channels are widely used in the construction industry for mounting electrical conduits, pipes, and HVAC systems. The roll-formed strut channels provide a strong and versatile support system for these components, allowing for easy installation and adjustment.

- Electrical installations: Strut channels are used to organize and support electrical cables, wire trays, and other electrical components. The channels provide a secure pathway for the cables, helping to reduce clutter and ensure proper cable management.

- Solar panel mounting: Strut channels are utilized in the installation of solar panels on rooftops or ground-mounted systems. The channels provide a framework for mounting and securing the solar panels, allowing for easy adjustment and positioning to optimize solar energy capture.

- Shelving and storage systems: Roll-formed strut channels are employed in the manufacturing of shelving and storage systems for warehouses, retail spaces, and industrial facilities. The channels act as support frames for shelves, racks, and other storage structures, providing strength and durability.

- Exhibition and display systems: Strut channels are utilized in the creation of exhibition booths, trade show displays, and retail fixtures. The channels serve as a framework for assembling modular structures that can be easily disassembled and reconfigured for different events or display setups.

- Automotive industry: Strut channels find applications in the automotive industry for the installation of wiring harnesses, cable trays, and mounting brackets. The channels provide a robust and reliable solution for organizing and securing electrical components in vehicles.

- Conveyor systems: Roll-formed strut channels are employed in conveyor systems to support and guide the movement of materials or products. The channels serve as a framework for mounting rollers, guides, and other conveyor components.

how to choose strut channel roll forming machine?

Choosing the right strut channel roll forming machine involves considering several key factors. Here are some factors to consider when selecting a strut channel roll forming machine:

- Production requirements: Determine your production needs in terms of the volume of strut channels you require. Consider factors such as the expected output per hour or per day. This will help you determine the speed and capacity requirements of the machine.

- Strut channel specifications: Define the specific dimensions, profiles, hole patterns, and other features required for your strut channels. Ensure that the machine you choose can accommodate the desired specifications and has the necessary tooling options or flexibility to meet your needs.

- Material compatibility: Consider the type and thickness of the materials you will be using, such as steel or aluminum. Ensure that the machine is designed to handle the specific material type and thickness range you require. Some machines may have limitations in terms of the material thickness they can process effectively.

- Automation and control: Evaluate the level of automation and control offered by the machine. Modern roll forming machines often feature computerized controls that allow for precise adjustments, monitoring, and data collection. Automation features can enhance efficiency, accuracy, and ease of operation.

- Flexibility and customization: Assess whether the machine allows for easy changeovers and adjustments to accommodate different strut channel profiles or dimensions. Consider if it offers customization options, such as the ability to create various hole patterns or slots, to meet specific project requirements.

- Quality and reliability: Look for a machine from a reputable manufacturer known for producing high-quality and reliable equipment. Read customer reviews and consider the machine’s performance track record to ensure its reliability and durability.

- After-sales support and service: Check the availability of technical support, training, and maintenance services provided by the manufacturer or supplier. A reliable after-sales support network can be crucial for troubleshooting, spare parts availability, and ongoing machine maintenance.

- Cost and ROI: Consider the machine’s price in relation to your budget and the expected return on investment. Compare prices, features, and capabilities from different suppliers to ensure you get the best value for your investment.

- Safety features: Verify that the machine incorporates appropriate safety features to protect operators and meet safety regulations. This can include features such as emergency stop buttons, safety guards, and interlock systems.

By carefully considering these factors and conducting thorough research, you can choose a strut channel roll forming machine that meets your specific production needs, quality requirements, and budget constraints.

Reviews

There are no reviews yet.