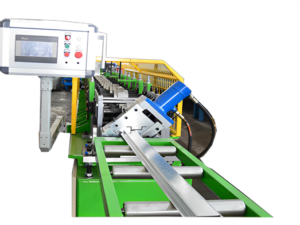

Metal steel structure deck floor deck roll forming machine could produce floor deck, roof deck, form deck and vigacero (more popular in Peru) according to your drawing.

The normal machinable thickness range of our steel deck roll forming machine is 0.8-1.2mm, the standard or more used in international market is Gauge 22, 20, 18, 16 (0.75-1.5mm), working raw material is PPGI, Galvanized steel etc. We confirm the machine’s configuration according to your drawing, specially the pitch and height of each wave. Sussman Machinery is always your best choice of metal deck roll forming machine.

Technical Parameter of Metal steel structure deck floor deck roll forming machine

| Item NO | Description | Unit Type | RF-DF |

| 1 | Steel Thickness | mm | 0.75 -1.5mm |

| 2 | Forming Speed | m/min | 0-20m/min |

| 3 | Roller stands | stand | 28-30 |

| 4 | Roller Material |

Gcr15 chromed

HRC55-60 |

|

| 5 | Shaft diameter | Ф90mm | |

| 6 | Main Motor Power | kw | 11*2kw |

| 7 | Hydraulic cutting Power | kw | 5.5 |

| 8 | Hydraulic pressure | Mpa | 12 |

| 9 | Power Supply |

220V, 60HZ,3 phase

|

|

| 10 | Tolerance | mm | 1.5 |

| 11 |

Material of cutting

|

Cr12mov | |

| 12 | Control system |

PLC with touch screen

|

|

| 13 | DRIVE system | Chain | 1.6 inches |

Machine List

| No | Name | Quantity |

| 1 | 15 ton Hydraulic De-coiler with Coil Car | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | PLC system | 1 unit |

| 4 | Hydraulic station | 1 unit |

| 5 | 12 Meters Auto Stacker | 1 unit |

Working Flow of Machine

Uncoiling—Feeding&Leveling–Roll forming—Cutting—Products collecting

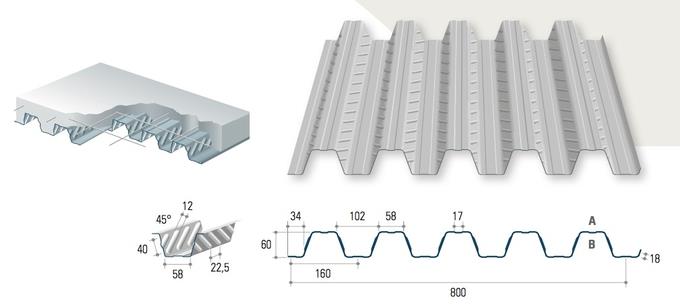

Standard Profile Drawing of product

Application

What is deck roll forming machine?

A deck roll forming machine is a type of industrial machinery used in the construction industry to produce metal decking panels, also known as floor or roof decking. Decking panels are commonly used in commercial and residential construction to create sturdy and reliable flooring systems.

The roll forming process involves feeding a continuous strip of metal, typically steel, through a series of roller dies. These dies gradually shape the metal into the desired profile, forming the decking panels. The process is continuous and automated, allowing for high-volume production with consistent quality.

Deck roll forming machines are designed to handle various types of decking profiles, such as corrugated or ribbed patterns. The specific profile is determined by the roller dies installed in the machine, which can be customized according to the desired design specifications.

The machine typically includes a decoiler to hold and feed the metal strip, a series of roller dies arranged in a sequential order, and a cutting mechanism to shear the finished panels to the desired length. Some machines may also have additional features, such as embossing or perforating capabilities to add texture or functionality to the decking panels.

Deck roll forming machines offer several advantages in the manufacturing process. They provide high efficiency and productivity, as they can produce large quantities of decking panels in a short period. The machines are also known for their accuracy and precision, ensuring consistent dimensions and quality throughout the production process.

Overall, deck roll forming machines play a vital role in the construction industry by enabling the efficient and cost-effective production of metal decking panels, which are essential components in the construction of floors and roofs.

application of double deck roll forming machine

- Roofing and Wall Cladding: The double deck roll forming machine can be used to manufacture metal roof panels and wall cladding systems. The two decks can produce different profiles, such as corrugated or standing seam panels, which are commonly used in residential, commercial, and industrial buildings.

- Shelving and Racking Systems: Double deck roll forming machines are utilized in the production of metal shelving and racking systems for warehouses, retail stores, and other storage facilities. The two decks can create different shelf or beam profiles, allowing for the efficient manufacture of diverse shelving products.

- Garage Door Tracks: Garage doors often require tracks that guide the door’s movement. A double deck roll forming machine can produce both the vertical and horizontal tracks simultaneously, increasing production efficiency and reducing manufacturing time.

- Partition Systems: In office buildings and commercial spaces, partition systems are used to create separate areas or rooms. A double deck roll forming machine can manufacture the various profiles required for partition systems, such as studs, tracks, and connectors.

- Fencing and Guardrails: Double deck roll forming machines can produce different profiles used in fencing and guardrail systems. These profiles include pickets, rails, and posts, which are essential components for constructing secure and durable fences and guardrails.

- Automotive Components: Double deck roll forming machines can be employed in the automotive industry to manufacture various components, such as roof racks, door frames, window channels, and trim profiles. The two decks enable the simultaneous production of different profiles used in different parts of the vehicle.

Scope of use of floor deck roll forming machine

The scope of use for a floor deck roll forming machine is primarily in the construction industry, where floor decking panels are widely utilized in various types of buildings, including commercial, industrial, and residential structures. Here are some specific applications and uses of a floor deck roll forming machine:

- Composite Floor Systems: Floor deck roll forming machines are commonly used to produce composite floor decking panels. These panels consist of a steel sheet or metal deck that serves as a formwork for concrete, creating a composite floor system. Composite floor systems offer strength, durability, and fire resistance, making them ideal for multi-story buildings, parking garages, and mezzanine floors.

- Roofing Systems: While floor deck roll forming machines are primarily used for floor decking, certain types of decking profiles can also be suitable for roofing applications. These profiles provide a stable base for roofing materials, such as insulation and waterproofing membranes, and can be used in low-slope or flat roof constructions.

- Elevated Platforms and Walkways: In industrial settings, floor deck roll forming machines can produce decking panels used for elevated platforms, catwalks, and walkways. These platforms provide safe and stable access to machinery, equipment, and elevated areas within factories, warehouses, and construction sites.

- Bridge Decks: Floor deck roll forming machines can manufacture decking panels that are used as bridge decks in infrastructure projects. These panels offer structural support, rigidity, and durability for bridge construction, ensuring the safe passage of vehicles and pedestrians.

- Sound Insulation and Vibration Control: Floor deck panels produced by roll forming machines can incorporate features such as embossing or perforations to enhance sound insulation and vibration control properties. These specialized decking panels find applications in buildings, theaters, recording studios, and other noise-sensitive environments.

- Retrofitting and Renovations: Floor deck roll forming machines are also used in retrofitting or renovation projects where existing floors need to be reinforced or upgraded. The machines can produce decking panels that are compatible with the existing floor system, improving load-bearing capacity, structural integrity, and overall performance.

advantages of steel deck roll forming machine

- High Efficiency and Productivity: Steel deck roll forming machines are designed for continuous and automated production. They can produce a large volume of decking panels in a short period, maximizing productivity and efficiency. The machines can operate at high speeds, ensuring rapid output and reducing production time.

- Customization and Flexibility: Steel deck roll forming machines can be customized to produce decking panels with various profiles, sizes, and configurations. The roller dies can be easily adjusted or changed to accommodate different design specifications, allowing for flexibility in meeting customer requirements. This versatility enables the production of a wide range of decking panel designs for diverse construction applications.

- Consistent Quality and Precision: Roll forming machines are known for their accuracy and precision in shaping metal. Steel deck roll forming machines ensure consistent dimensions, smooth edges, and uniformity in the decking panels. The automated process minimizes human error, resulting in high-quality products with tight tolerances and precise specifications.

- Cost-Effective Production: Steel deck roll forming machines offer cost advantages in the production of steel decking panels. The continuous roll forming process eliminates the need for separate cutting, punching, and forming operations, reducing labor costs and material waste. The machines operate efficiently with minimal energy consumption, contributing to overall cost savings.

- Durability and Strength: Steel decking panels produced by roll forming machines are renowned for their durability and strength. The panels are made from high-quality steel, providing excellent load-carrying capacity and structural stability. They can withstand heavy loads, foot traffic, and extreme weather conditions, making them ideal for commercial and industrial flooring systems.

- Reduced Material Handling: Steel deck roll forming machines typically include an integrated decoiler, which feeds the steel strip directly into the machine. This eliminates the need for manual handling of heavy coils and improves safety in the production process. The automated material feeding system ensures smooth and continuous operation.

- Integration with Downstream Processes: Steel deck roll forming machines can be seamlessly integrated with other downstream processes, such as cutting, embossing, perforating, and stacking. This allows for efficient post-processing and customization of the decking panels, enhancing their functionality and aesthetic appeal.

Reviews

There are no reviews yet.