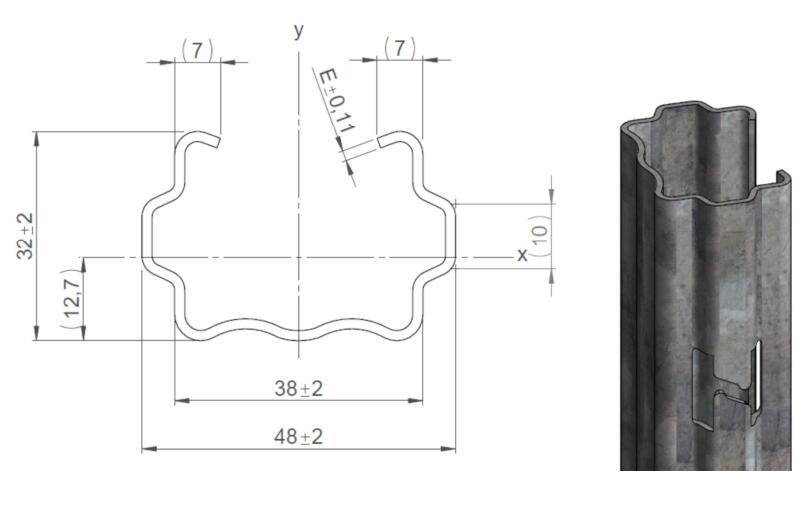

Profile Drawing of Roll forming machine design Vineyard stakes post Profile

Working flow of Roll forming machine design Vineyard stakes post Profile

Uncoiling—leveling—servo feeding— punching press–Roll forming—servo cutting—Products collecting

Machine parts list of Roll forming machine design Vineyard stakes post Profile

| S.N | Equipment name | Quantity |

| 1 | Manual De-coiler | 1 set |

| 2 | Leveling device NC300mm | 1 set |

| 3 | Servo feeding device 300mm | 1 unit |

| 4 | Press machine JH21-80 | 1 unit |

| 5 | Main roll forming machine | 1 set |

| 6 | Servo following cutting | 1 set |

| 7 | Hydraulic station | 1 set |

| 8 | Control system ( including control box) | 1 set |

| 9 | Out tables | 1 unit |

| 10 | Spare parts | 1 package |

Technique data of Roll forming machine design Vineyard stakes post Profile

1. 3 tons manual De-coiler

- Coil inner Diameter: ¢460mm~520mm

- Max out diameter of the coil: ¢800mm

- Expansion: with 4 palms, with brake

- Max Coil Width: 500mm

2. Leveling device

- 7 rolls leveling, 3 rolls up and 4 rolls down, roller leveler rolls is more smaller, get flatting better.

- Diameter is Ø 70mm, chrome and HRC60 heat treatment to secure the smooth surface

- Leveling Raw Material thickness:1.5-2.0mm

- Max Leveling Raw Material width: 300mm

- Motor: 1.8kw, drive faster, can adjust the speed

3. Feeding device

Feeding Servo feeding motor: 1.8KW (Yaskawa, Japanese Brand)

Description: servo feeding can control the punching distance in precision, controlled by PLC, and the feeding tolerance can be+-0.05mm, the servo motor can control the speed, and can accept the input signal, and react quickly, and performance well, the touch screen can display the rotating speed, the length and the quantity, it can be controlled by the manual and auto modes.

4. Press machine

- Series JH21-80

- Brand name: Yangli

- JH21 series press machine description:

- JH21series open back press with dry clutch and hydraulic overload protector

- Welded body with steel plate and high intensity.

- Main motor is made by Siemens.

- Adopts combined pneumatic friction clutch and brake.

- Cluster gear adopts the flooding oil lubrication.

- Six-face rectangle lengthen guide; JH21-315B/400B adopts eight-face lengthen guideway.

- Equipped with hydraulic overload protecting device.

- JH21-25/25B/45 adopts manual shut height adjustment,among these types JH21-25/45 adopts scale display and JH21-25B with digital display.JH21-63 and above type adopts electric shut height adjustment with digital display.

- JH21-45 can equip with die set height adjustment motor, the value will be displayed by digital.

- JH21-25B, JH21-45 and above type equipped with balance cylinder.

- Duplex valves imported.

- Electric compelling grease lubrication system.

- Balancing cylinder adopts manual lubrication system.

- One set of blowing device.

- Controlled by PLC with international brand.

- Buttons, indicators, AC contactors, air circuit breakers and other controlling devices are imported from international brand.

- Equipped with optional air cushion device, automatic feed shaft and photoelectric protector, which can used to work with various automatic equipments.

Main Roll forming machine technique data

- Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or blank steel

- Working Speed: about 10-12 meters / min (include cutting time and punching time)

- Forming machine: about 16 stations

- Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

- Material of Shaft: 45# Advanced Steel (Diameter: 75mm), thermal refining

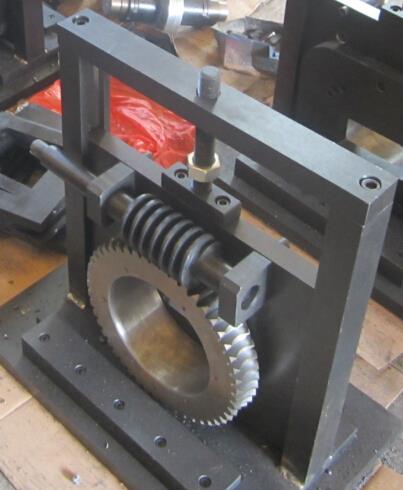

- Drive system: Gear box driven

- Main Power with reducer: 11KW WH Chinese Famous

- Cutting: Hydraulic Cutting Cr12mov

- Material of Cutting Knife: Cr12Mov, Quench HRC58-62

- Hydraulic Station Power: 4KW Famous Chinese Brand

- The whole machine is controlled by industry computer-PLC.

- PLC–Panasonic, English and Chinese Language

- Encoder–Omron, Japan

- Electric parts–Schneider

- Machine operation: Manual and full automatic mode at same time with limit switches, and panel support device

- Power supplier: 380V, 50 Hz, 3Phase

Gear box drive

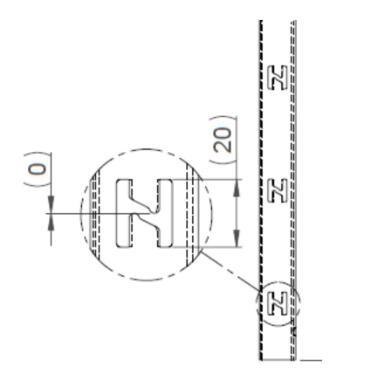

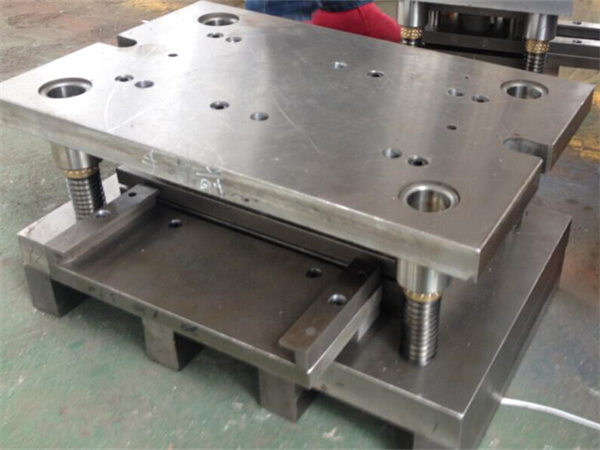

Punching die sets

Punching die sets description

As for the profiles, total need 1 set of punching die set, when the punching heads broke, they can be removed, and changed by the new punching heads, get guide pins for the punching moulds

Punching moulds material: Cr12Mov Quenching HRC58-62degree Shanghai NO.5 Steel (China best brand for steel)

Servo following Cutting:

- The cutter blade material: Cr12mov HRC58-62 degree

- Blades number: 1 set

- Cutting after forming: Cut the sheet after roll forming to required length

- Cutting motion: The main machine automatically cut, following and back, Non stop.

- Material of blade: CR12Mov with heat treatment

- Length measuring: Automatic length measuring

- Tolerance of length: 6m±0.5mm

Twister for each profile to make profiles straight

Quantity: 1 piece

Main roll forming machine share list

- De-coiler

- Leveling machine

- Servo Feeding

- Punching press machine

- Punching die set

- main frame of the machine

- Main Motorand main drive

- Hydraulic station

- PLC Control box

- Cutter holder

- Out tables

- PLC control box

Out tables

- Length: 4 meters

- Number: 1 unit

Total machine specification

- the outline of the machine: about 25 meters*2 meters*1.2 meters

- total weight: about 10 tons

- shipping container 1*20+1*40 feet GPcontainers

What are the factors of roll forming machine design?

- Material and Profile Requirements: The design process starts by understanding the specific requirements of the desired profile or shape to be produced. This includes the material type, thickness, width, and other specifications.

- Roll Forming Stands: The roll forming stands consist of a series of rollers arranged in a sequential order. Each set of rollers progressively bends the material into the desired shape. The number of stands and their configurations depend on the complexity of the profile and the number of bends required.

- Roller Design: The design of rollers is crucial for achieving precise and consistent bending of the material. Rollers are typically designed with different profiles to gradually form the material into the desired shape. The roller diameters, profiles, and materials are selected based on the specific requirements.

- Driving Mechanism: Roll forming machines use a driving mechanism to pull the material through the rollers. This mechanism may involve gears, chains, or direct drives, depending on the application and desired speed. The driving system should be capable of providing the necessary force and speed for smooth material feeding.

- Tooling and Changeover: Roll forming machines often require tooling sets that are specific to each profile. The design should consider the ease of changing the tooling sets when switching between different profiles. Quick-change systems and adjustable setups can improve efficiency and reduce downtime during changeovers.

- Control System: A control system is essential for operating the roll forming machine. It may include human-machine interfaces (HMIs), sensors for monitoring material position and dimensions, and programmable logic controllers (PLCs) to automate the machine’s functions.

- Safety Features: Safety is a critical aspect of machine design. Proper guarding, emergency stop buttons, and interlocks should be incorporated to ensure the safety of operators and prevent accidents.

During the design process, engineers consider factors such as material properties, dimensional tolerances, production speed, and efficiency to optimize the machine design for specific applications. Computer-aided design (CAD) software and simulation tools are commonly used to assist in the design process, allowing engineers to visualize the machine’s operation and make necessary adjustments before fabrication and assembly.

what is profile roll forming machine?

A profile roll forming machine is a type of machinery used to shape metal strips or sheets into specific profiles or cross-sections. It is commonly used in various industries, including construction, automotive, and manufacturing.

The process of roll forming involves passing a continuous metal strip or sheet through a series of rollers, each performing a specific bending or forming operation. These rollers are often designed in sets, with each set gradually shaping the metal into the desired profile. The machine’s components typically include a decoiler, feeding system, roll forming stations, and a cutting or shearing mechanism.

The profile roll forming machine is highly versatile and can produce a wide range of profiles with different shapes, sizes, and complexities. Some examples of profiles that can be created using a roll forming machine include C-shaped profiles, Z-shaped profiles, U-shaped profiles, hat profiles, and custom profiles specific to the application requirements.

The advantages of profile roll forming machines include high production efficiency, consistent quality, and the ability to handle a variety of materials, including steel, aluminum, and stainless steel. These machines are programmable and can be easily adjusted to produce different profiles by changing the tooling and adjusting the roller positions.

Profile roll forming machines are essential for the mass production of profiles used in industries such as building construction, automotive body parts, storage systems, and electrical enclosures, among others.

does omega profile roll forming machine is a kind of profile roll forming machine?

Yes, an omega profile roll forming machine is a specific type of profile roll forming machine. The term “omega” refers to the shape of the profile being produced, which resembles the Greek letter Omega (Ω).

An omega profile is a popular profile used in various applications, especially in the construction industry. It is typically characterized by its wide, “U” shape with flanges on both sides and a deep channel in the center. Omega profiles are commonly used for framing, support structures, and in the installation of suspended ceilings, among other applications.

An omega profile roll forming machine is specifically designed to produce omega profiles with high precision and efficiency. It is equipped with dedicated tooling and rollers that are designed to shape the metal strip or sheet into the desired omega profile.

The machine’s operation involves feeding the metal strip or sheet into the machine, where it passes through a series of roll forming stations. Each station gradually bends and forms the metal until it reaches the final omega profile shape. The machine may also include additional stations for punching or cutting operations, depending on the specific requirements of the omega profile being produced.

Omega profile roll forming machines are widely used in the manufacturing of building components, partitions, cladding systems, and other applications where omega profiles are required. They offer the advantages of high production efficiency, consistent quality, and the ability to produce omega profiles with different sizes and specifications.

Reviews

There are no reviews yet.