For automatic metal fence post roll forming machine system, we need three machines, which is fencing sheet machine, fencing post machine, fence rail machine, the material thickness is 0.4-0.7mm, material will be galvanized steel or color steel, automatic cut any length you want, fencing is very popular in Australia, New Zealand.

The Roll forming machine for Fence post guide rail can be installed on top of limestone walls with panels stepped, post and rail fencing is a traditional and cost-effective form of fencing. Its simple design makes it the ideal choice for a DIY project, especially on sloping sites and uneven ground, and it is widely used for house garden, school, factory, etc.

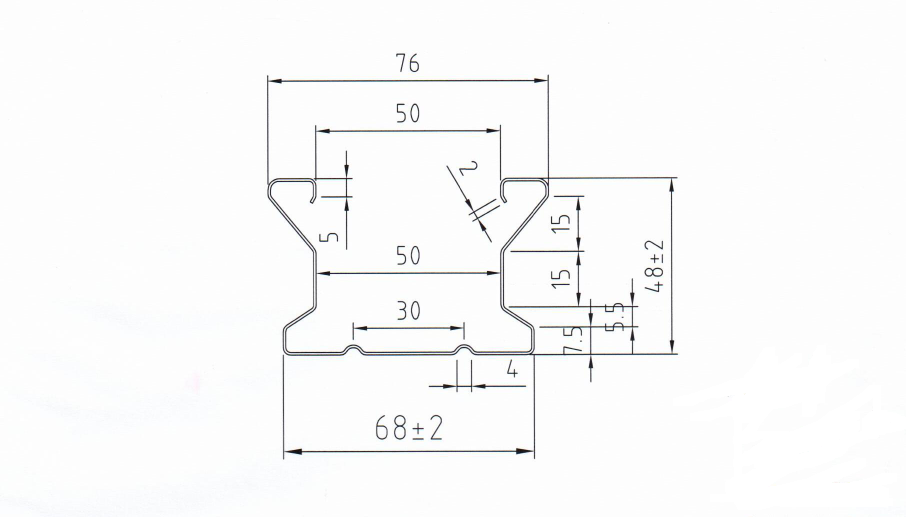

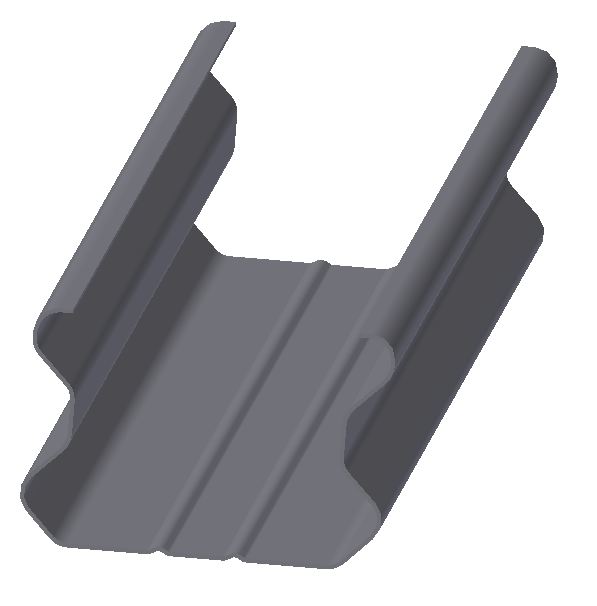

Profile of the product

(Basis on customer’s requirement to design)

|

Machine list

|

3 ton manual de-coiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| Hydraulic cutting device | 1 set | |

| PLC Control box | 1 set | |

| Hydraulic station | 1 set | |

| 4m out table | 1 set | |

| Safety cover | 1 set |

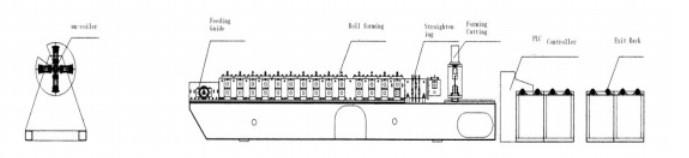

Technological process

Uncoiling—feeding with guide——Roll forming——Cutting—Products collecting

The external of machine

| Items |

Specifications

|

|

|

Material of coil

|

Material Thickness |

0.5-0.7mm galvanized, G235-350Mpa

|

| Un Coiler | 3 tons manual | |

|

Forming system

|

Rolling Speed |

About 10-20 m/min

|

| Roller Stations |

About 21 stations

|

|

| Roller Material |

45# Steel with quenching 60mm shaft

|

|

| Maim Motor Power | 7.5 kw | |

| Hydraulic cutting Power | 3 kw | |

|

Cutting

system |

Material Of Cutting |

CR12 with quench treatment

|

| Hardness | HRC58-62 | |

| Tolerance | ±1.5mm | |

|

Electrical control system

|

Electric Source |

380V, 50HZ,3 phase

Also can satisfy Customer’s require |

| Control System |

PLC with touch screen

|

|

| Weight | About 3.5 tons | |

| Way Of Drive |

1 inch single chain

|

|

| Size of machine |

Length 10000mm* Width 800mm* Height 1500mm

|

Details of each composition

1.Decoiler: 3 tons passive decoiler

- Diameter: 460-520mm expansion.

- Expansion:manaul

- Capacity: 3000kg per mandrel

- Max Coil Width: 500mm

2. Cutting way

- Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

- Material of blade: CR12mov with heat treatment

- Length measuring: Automatically

- Tolerance of length: + 1.5mm

- In order to get the perfect profiles, we recommend the post hydraulic cutting by changing the cutting moulds. It is easy to operate.

3. Out Table

- Length : 4 meters

- Quantity: 1 units

4. Control Box:

- (1) Power supplier: 380V, 50 Hz, 3Phase (adjusted with therequestment)

- (2) Length & quantity measurement automatically;

- (3) Length & quantity controlled by PLC,

- (4) Length inaccuracy can be amended easily.

- (6). Control panel: Button-type switch and touch screen

- (7) The language in the touch screen: English and Chinese

- (8) Unit of length: millimeter (switched on the control panel)

what is guide rail roll forming machine?

A guide rail roll forming machine is a type of industrial machinery used to manufacture guide rails or guardrails. Guide rails are commonly used in various applications, including industrial equipment, transportation systems, construction projects, and more. They provide support, guidance, and safety by directing the movement of objects or vehicles along a predetermined path.

The roll forming process involves feeding a continuous strip of metal through a series of rollers, gradually shaping it into the desired profile. The guide rail roll forming machine is specifically designed to form guide rails with consistent dimensions and precise profiles.

The machine typically consists of several components, including a decoiler to hold the metal coil, a leveling unit to flatten the strip, a series of roll forming stations with adjustable rollers, and a cutting mechanism to shear the formed guide rail to the desired length. Additional features may include punching units to create mounting holes or slots in the guide rail.

The guide rail roll forming machine is controlled by a computerized system that allows operators to set the desired dimensions and parameters. This automation ensures high production efficiency, accuracy, and repeatability.

how about oem slide rail roll forming machine?

An OEM slide rail roll forming machine is a specific type of roll forming machine designed to manufacture OEM (Original Equipment Manufacturer) slide rails. Slide rails, also known as linear guides or linear motion systems, are essential components used in various applications, including machinery, automation systems, and industrial equipment.

The OEM slide rail roll forming machine follows a similar operating principle as the guide rail roll forming machine but is tailored specifically for the production of slide rails. It typically consists of a series of roll forming stations, adjustable rollers, a cutting mechanism, and other components necessary for the manufacturing process.

The machine takes a continuous strip of metal, such as steel or aluminum, and feeds it through the roll forming stations. The metal strip is gradually shaped and formed into the desired profile, which is specific to the OEM slide rail design. The machine ensures the consistent dimensions and precise profiles required for OEM slide rails.

Depending on the specific requirements of the OEM slide rails, the machine may include additional features such as punching units for creating mounting holes or slots, bending units for forming complex shapes, or coating units for adding protective finishes.

Similar to other roll forming machines, the OEM slide rail roll forming machine is typically computer-controlled, allowing operators to input the desired dimensions and parameters for the slide rail production. This automation ensures high efficiency, accuracy, and consistency in the manufacturing process.

application of slide rail roll forming machine

- Machinery and Equipment: Slide rails are essential components in machinery and equipment that require linear motion, such as CNC machines, cutting machines, assembly lines, industrial robots, printing machines, and packaging equipment. They provide smooth and precise movement for the proper functioning of these machines.

- Automation Systems: Slide rails are utilized in automation systems for smooth and controlled linear motion. They are employed in conveyors, material handling systems, pick-and-place machines, and other automated systems where precise and reliable movement is required.

- Industrial Applications: Slide rails find application in various industrial sectors, such as automotive manufacturing, aerospace, electronics, textile machinery, food processing, pharmaceuticals, and more. They are used for positioning, guiding, and transferring components or products in these industries.

- Medical Equipment: Slide rails are crucial in medical equipment, including diagnostic machines, medical imaging systems, laboratory instruments, patient beds, operating tables, and medical device manufacturing. They provide stability, accuracy, and controlled motion in medical applications.

- Furniture and Cabinetry: Slide rails are commonly used in furniture and cabinetry, such as drawer slides, keyboard slides, monitor arms, sliding door systems, and adjustable shelving. They enable smooth and easy movement of drawers, doors, and other components.

- Transportation: Slide rails are employed in various transportation systems, including railways, automotive seating systems, aircraft seating, and vehicle accessories. They ensure proper movement and adjustability in seats, sunroofs, windows, and other movable parts.

what is din rail roll forming machine?

A DIN rail roll forming machine is a specialized type of roll forming machine used to manufacture DIN rails. DIN rails are standardized metal rails used for mounting various electrical and electronic devices in control panels, distribution boards, and industrial enclosures.

The DIN rail roll forming machine is designed to produce DIN rails with specific profiles and dimensions according to the DIN (Deutsches Institut für Normung) standards. These standards ensure compatibility and uniformity of DIN rails across different manufacturers and applications.

The machine typically consists of a series of roll forming stations, adjustable rollers, a cutting mechanism, and other components necessary for the manufacturing process. It takes a continuous strip of metal, usually steel, and feeds it through the roll forming stations.

The metal strip is gradually shaped and formed into the specific profile required for DIN rails. The roll forming process involves a combination of bending, folding, and punching operations to achieve the desired shape and features, such as mounting holes or slots.

The DIN rail roll forming machine is typically computer-controlled, allowing operators to input the required dimensions and parameters for the DIN rail production. This automation ensures high precision, efficiency, and repeatability in the manufacturing process.

DIN rails produced by the roll forming machine are widely used in electrical installations, automation systems, control panels, and other industrial applications. They provide a standardized and reliable method for mounting and organizing electrical components, such as terminal blocks, circuit breakers, relays, power supplies, and more.

Reviews

There are no reviews yet.