T Bar Roll Forming Machine Technical Data

| Model number | T grid machine |

| Material Thickness | 0.25-0.5mm |

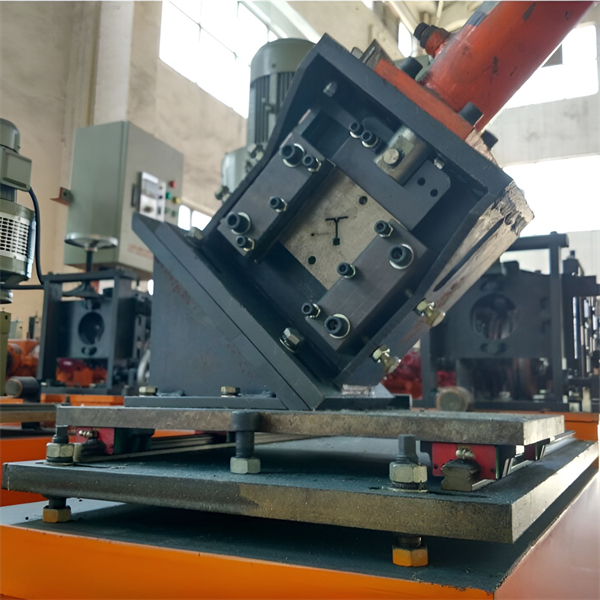

| Punching moulds | 4 sets |

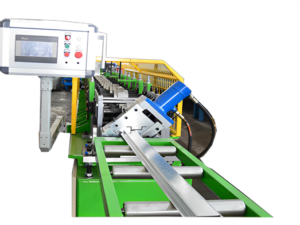

| Roller Stations |

About 16 stations forming

|

| Roller Material |

Gcr15 Steel with quenching 55-60°

|

| Shaft Material |

45# Steel Diameter 60mm shaft

|

| Material Of Cutting |

CR12Mov with quench treatment

|

| Weight | About 5 tons |

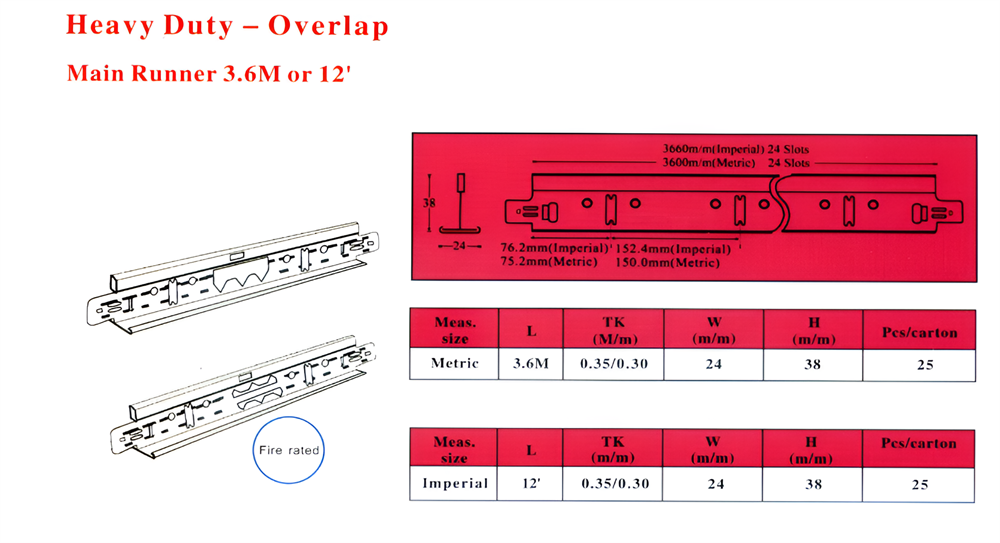

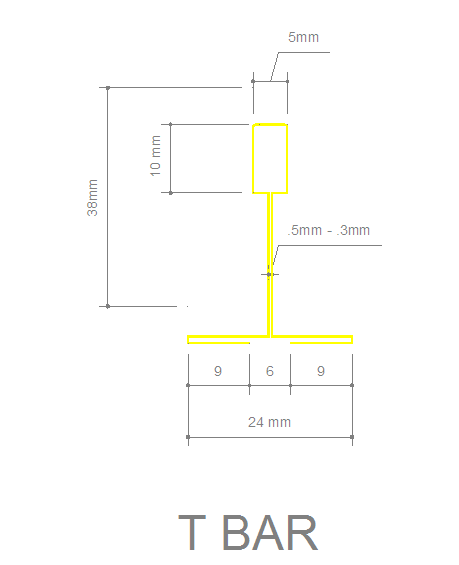

Profile Drawing

Application

what is ceiling t bar roll forming machine?

A ceiling T-bar roll forming machine is a specialized industrial machine used to produce T-shaped metal profiles commonly used in suspended ceiling systems. It is designed to efficiently roll-form continuous lengths of metal strips into T-bars with specific dimensions and shapes.

The roll forming process involves passing a flat metal strip through a series of rollers, each designed to gradually bend and shape the strip into the desired T-bar profile. The machine typically includes multiple sets of rollers, each performing a specific bending or shaping operation.

The T-bar profiles produced by the machine are commonly used in suspended ceiling systems to support ceiling tiles and provide a framework for lighting fixtures and other ceiling components. The T-bars are installed in a grid pattern and are typically suspended from the building structure using hangers and wires.

Ceiling T-bar roll forming machines are highly automated and can produce T-bars with consistent dimensions and high production rates. They are essential for manufacturing companies involved in the production of suspended ceiling systems and provide an efficient and cost-effective solution for producing large quantities of T-bars.

what is ceiling t grid roll forming machine?

Apologies for the confusion in my previous response. A ceiling T-grid roll forming machine is a specialized industrial machine used to produce T-shaped metal grids that are used in suspended ceiling systems.

Ceiling T-grids, also known as ceiling T-bars or ceiling grid systems, are an essential component of suspended ceilings. They provide a framework for attaching and supporting ceiling tiles, lighting fixtures, and other ceiling components. The T-grid system consists of main T-bars and cross T-bars that form a grid pattern, creating a stable structure to hold the ceiling tiles in place.

A ceiling T-grid roll forming machine is designed to efficiently produce these T-grid profiles. It uses a roll forming process where a flat metal strip is fed into the machine and passed through a series of rollers. The rollers gradually shape the strip into the desired T-grid profile, forming the main T-bars and cross T-bars.

The machine typically includes various stations with different sets of rollers and cutting mechanisms to achieve the necessary shapes and dimensions for the T-grid components. It can handle different gauges of metal strips and produce T-grids of various lengths.

Ceiling T-grid roll forming machines are highly automated and can operate at high production speeds. They offer precise control over the dimensions and shapes of the T-grid profiles, ensuring consistency and accuracy in the manufacturing process. These machines are widely used in the construction industry by manufacturers of suspended ceiling systems to produce T-grids in large quantities efficiently.

What are the differences between these two devices?

The main difference between a ceiling T-bar roll forming machine and a ceiling T-grid roll forming machine lies in the specific type of metal profiles they produce for suspended ceiling systems.

- Ceiling T-bar roll forming machine: This machine is used to produce T-shaped metal profiles, commonly known as T-bars. T-bars are typically used as support structures in suspended ceilings. They are long, continuous metal strips with a T-shaped cross-section. T-bars are installed in a grid pattern and are responsible for providing support for the ceiling tiles and other ceiling components.

- Ceiling T-grid roll forming machine: This machine is specifically designed to produce the grid system used in suspended ceilings, which consists of main T-bars and cross T-bars. The main T-bars are longer and run perpendicular to the cross T-bars, forming a grid pattern. The cross T-bars intersect the main T-bars, creating a stable framework for attaching the ceiling tiles and other components. The T-grid system provides a modular and flexible approach for constructing suspended ceilings.

In summary, while both machines are used in the production of suspended ceiling systems, the ceiling T-bar roll forming machine produces individual T-bars, while the ceiling T-grid roll forming machine produces the complete T-grid system, which includes the main T-bars and cross T-bars.

Reviews

There are no reviews yet.