Technical parameter

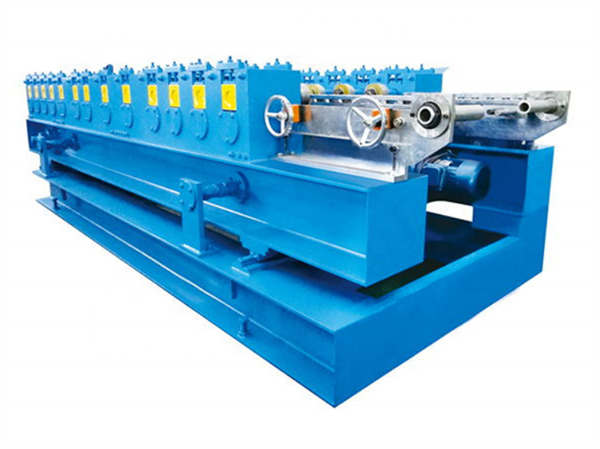

- Shutters Box Series Forming Machines specification: forming thickness 0.5-1.0mm, yield strength≤G250Mpa

- 2. Forming speed: 10M/min (EXCLUDING CUTTING STOP TIME)

- Forming roller: about 16/8 stations

- Main motor power: 5.5KW,

- Roller material: Gcr15 steel, surface coated with chrome

- Main shaft material: 45# steel

- Main axis dia.: ¢80mm

- Hydraulic cutting pressure: 10-12Mpa

- Cutting method: hydraulic powered, cutting after roll forming.

- Cutting blade material: Cr12 quenching treatment

- Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤1.5mm

Roll forming line comprised equipment

Shutters Box Series Forming Machines comprised of 3T manual uncoiler, feeding guiding, roll forming machine, cutting equipment, electrical controlling system, output table.

Flow Chart

Uncoiling – feed Guiding–Roll forming –fly saw cutting – Run-out table

Installed machine

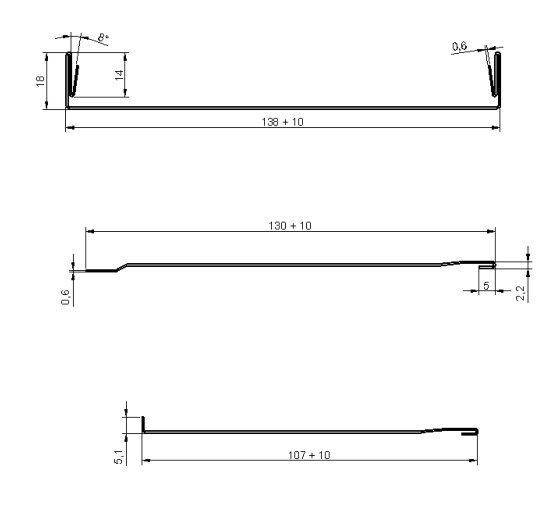

Shutters Box Series Forming Machines can be divided into two-pieces installed and three-pieces installed machine.

1. Two Pieces-Installed

2. Three-Pieces Installed

Application

The shutter box is widely used for the rolling shutter door to cover the shutter slat and the insulated shutters. The shutter box is made by the aluminum, it is light, rust proofing, and automatically controlled by the motor.

what is box forming machine?

A box forming machine, also known as a carton forming machine or a carton erecting machine, is a type of equipment used in the packaging industry to automatically form cardboard boxes or cartons. It is designed to streamline the box assembly process and increase efficiency in packaging operations.

Box forming machines typically take flat, pre-cut cardboard blanks or sheets and transform them into three-dimensional boxes by folding and sealing the necessary flaps and tabs. The machine uses a combination of mechanical, pneumatic, and sometimes robotic systems to perform these tasks.

The specific operation of a box forming machine may vary depending on its design and capabilities, but the general process involves the following steps:

- Feeding: Flat cardboard blanks or sheets are loaded into the machine’s feeding system.

- Folding: The machine folds the cardboard along predetermined crease lines to create the box’s main structure, forming the sides, bottom, and top flaps.

- Gluing or taping: Adhesive or tape application systems apply glue or tape to seal the box’s flaps securely.

- Box ejection: Once the box is fully formed and sealed, it is ejected from the machine, ready for further processing or packaging.

Box forming machines are used in various industries, including food and beverage, pharmaceuticals, cosmetics, e-commerce, and more, where products are often packaged in cardboard boxes for shipping, storage, or display purposes. These machines help automate the box assembly process, reduce labor costs, and improve production efficiency.

what is cardboard box forming machine?

A cardboard box forming machine, also known as a box making machine or box forming equipment, is a mechanical device used in the packaging industry to automatically produce cardboard boxes. These machines are designed to fold and glue flat sheets of cardboard or corrugated board into various box shapes and sizes.

The process typically involves the following steps:

- Feeding: The machine takes in flat cardboard sheets from a stack or roll and feeds them into the machine.

- Scoring and creasing: The machine scores and creases the cardboard sheets at specific points to facilitate folding.

- Folding: The scored sheets are folded along the crease lines to form the desired box shape.

- Gluing: Adhesive is applied to the necessary areas of the cardboard to hold the box together. This can be done using hot melt glue or other types of adhesives.

- Pressing: The folded and glued boxes are pressed or compressed to ensure a secure bond.

- Cutting and trimming: The machine may also incorporate cutting and trimming mechanisms to remove excess cardboard or create openings for handles or windows.

- Stacking or ejecting: The finished boxes are either stacked for further processing or ejected onto a conveyor belt for packaging and shipping.

Cardboard box forming machines are often used in industries that require large quantities of standardized boxes, such as shipping, e-commerce, food and beverage, and manufacturing. They help automate the box production process, increasing efficiency and reducing labor costs. These machines can produce a wide range of box styles, including regular slotted containers (RSC), die-cut boxes, folding cartons, and more.

applicaiton of box beam roll forming machine

A box beam roll forming machine is used to produce box beams, which are structural components commonly used in various industries for their strength and rigidity. Here are some applications of box beam roll forming machines:

- Construction industry: Box beams are widely used in the construction of buildings, bridges, and other infrastructure projects. They provide support and stability, especially in load-bearing structures. Box beams can be used for columns, roof trusses, floor beams, and other structural elements.

- Automotive industry: Box beams find applications in the automotive sector for chassis frames, suspension components, and body structures. They offer high strength-to-weight ratio and can withstand heavy loads, making them suitable for enhancing the structural integrity and safety of vehicles.

- Material handling and storage systems: Box beams are utilized in the manufacturing of racks, shelving units, and storage systems for warehouses, distribution centers, and industrial facilities. These systems require strong and durable components to support heavy loads and organize materials effectively.

- Industrial machinery: Box beams are commonly used in the construction of industrial machinery and equipment. They provide a sturdy framework for machines and help maintain their structural integrity, especially in heavy-duty applications.

- Renewable energy sector: Box beams are used in the construction of wind turbine towers, solar panel mounting systems, and other renewable energy structures. These applications require strong and durable components to withstand harsh environmental conditions and support the weight of the equipment.

- Agricultural equipment: Box beams are utilized in the manufacturing of agricultural machinery such as tractors, harvesters, and trailers. They provide structural support and durability to withstand the demanding conditions of agricultural operations.

- Aerospace industry: Box beams find applications in the aerospace sector for aircraft structures, such as wing supports, fuselage frames, and landing gear components. They offer high strength and rigidity while minimizing weight, crucial for aerospace applications where weight reduction is critical.

Box beam roll forming machines allow for efficient and cost-effective production of box beams in various sizes, profiles, and materials, including steel, aluminum, and other metals. These machines enable manufacturers to produce customized box beams with consistent quality, high precision, and rapid production speeds to meet the specific requirements of different industries.

Reviews

There are no reviews yet.