Что такое машина для формовки труб?

Профилегибочная машина для труб представляет собой производственную линию, которая используется для производства труб и труб. Его можно использовать в различных отраслях промышленности, таких как нефтехимическая, химическая и энергетическая. В машине для формования труб используется матрица для формирования трубы, и она имеет множество функций, которые делают ее эффективным инструментом.

Одним из преимуществ использования профилегибочного станка для труб является то, что он может производить продукцию с точными размерами. Матрицу можно регулировать для создания различных форм и размеров, что обеспечивает более стабильное производство. Кроме того, машина может быть настроена для работы с различными типами материалов. Это означает, что он может производить продукцию с определенными свойствами, такими как прочность и термостойкость.

Еще одним преимуществом использования профилегибочного станка для труб является его скорость. Процесс относительно быстрый по сравнению с другими производственными линиями, что означает, что он может быстро справляться с большими объемами производственных задач. Кроме того, матрица не требует особого обслуживания, поэтому машина может оставаться в рабочем состоянии в течение длительного периода времени.

Что такое роликовая формовочная машина для восьмиугольных труб жалюзийных дверей?

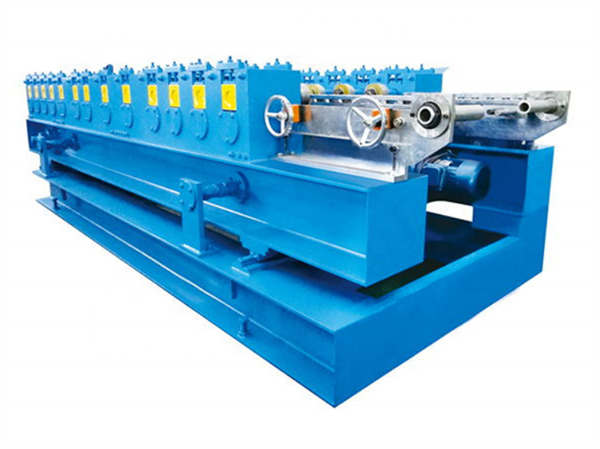

Наш станок для формовки восьмиугольных труб для ворот-жалюзи является важным оборудованием для производства высококачественных ворот-жалюзи. Он предназначен для производства восьмиугольных труб из различных материалов, таких как оцинкованная сталь, нержавеющая сталь, алюминий, медь, латунь и мягкая сталь, что делает его идеальным для широкого спектра применений.

Преимущества использования нашего станка значительны. Оно обеспечивает эффективное и точное производство, в результате чего получается надежный и долговечный конечный продукт. Кроме того, передовые технологии и функции, такие как гидравлические разматыватели, сервоподатчики, пуансоны, роликовые формирователи, серворезки и электрические/гидравлические системы, обеспечивают точность и скорость производственного процесса.

Кроме того, наша машина может увеличить производственную мощность и снизить производственные затраты, что делает ее ценной инвестицией для тех, кто работает в отрасли производства роллетных ворот. С нашим станком для формовки восьмиугольных труб для ворот-жалюзи вы можете обеспечить высококачественное и эффективное производство, отвечающее конкретным требованиям вашего приложения.

Как работает трубопрокатный станок?

Трубопрокатное оборудование используется для производства цилиндрических труб или труб с постоянной формой поперечного сечения. Процесс включает в себя подачу плоской полосы металла через ряд валков, которые постепенно изгибают и придают полосе форму трубы. Вот общий обзор работы трубопрокатного станка:

- Подготовка материала: Машина начинает работу с рулона или листа металла, обычно стали или алюминия. Рулон загружается на разматыватель, который постепенно подает полосу в машину.

- Станции формирования валков: Полоса проходит через ряд станций формирования валков, обычно расположенных линейно. Каждая станция состоит из набора валков, часто пары верхних и нижних валков. Валки точно расположены и предназначены для постепенного формирования полосы.

- Формирование формы трубы: По мере прохождения полосы через станции вальцевой штамповки валки оказывают давление и изгибающее усилие для придания полосе желаемой формы трубы. Валки постепенно сгибают полосу, формируя края вместе и создавая непрерывный шов.

- Сварка (опция): В некоторых случаях, если требуется непрерывная сварная труба, в машину может быть встроена дополнительная сварочная станция. Эта станция использует сварочный процесс, такой как высокочастотная индукционная сварка или лазерная сварка, для соединения краев полосы вместе, создавая сплошной шов.

- Определение размеров и резка: После формирования трубы она проходит через станции определения размеров. На этих станциях используются валки или другие механизмы для регулировки диаметра трубы до окончательного желаемого размера. Машина также может иметь станцию резки, где трубка отрезается до нужной длины.

- Отделка и штабелирование: После того как труба отрезана по длине, она проходит все необходимые процессы отделки, такие как снятие заусенцев или обработка поверхности. Затем готовые трубы обычно укладываются в штабеля или собираются для дальнейшей обработки или упаковки.

Важно отметить, что точная конструкция и принцип работы трубопрокатного станка могут варьироваться в зависимости от конкретного производителя и требуемой формы и технических характеристик трубы. Некоторые машины могут иметь дополнительные функции или возможности, такие как пробивка отверстий или дополнительные операции формовки, для удовлетворения конкретных требований.

что такое станок для изготовления жалюзийных дверей?

Станок для производства роллетных ворот, также известный как станок для формирования роллетных ворот, предназначен для производства роллетных ворот, которые обычно используются в коммерческих и промышленных зданиях в целях безопасности. Для придания формы и изготовления компонентов ворот-жалюзи станок использует процесс формирования рулонов. Ниже приводится обзор работы типичного станка для изготовления роллетных ворот:

- Загрузка материала: Работа машины начинается с загрузки сырья, обычно рулона оцинкованной стали или алюминия, на разматыватель. Рулон устанавливается на шпиндель и разматывается, чтобы получить непрерывную полосу материала для процесса формования.

- Формование рулонов: Полоса материала подается на станции формирования валков машины. Станции формирования рулонов состоят из серии специально разработанных роликов, которые постепенно придают материалу желаемый профиль. Эти ролики тщательно позиционируются и располагаются так, чтобы создать необходимые складки, изгибы и ребра жесткости компонентов жалюзийных ворот.

- Формирование профиля: Полоса проходит через несколько станций формирования валков, каждая из которых отвечает за формирование определенной части жалюзийной двери, такой как планки, направляющие и нижние планки. По мере прохождения полосы через станции валки изгибают и формируют материал, превращая его в требуемые профили.

- Резка и высечка: В зависимости от конструкции и требований машина может включать в себя станции резки и высечки. На этих станциях используются режущие ножи или перфораторы для резки компонентов жалюзийных ворот до нужной длины и создания пазов или отверстий для соединения и сборки.

- Тиснение и пробивка отверстий (опция): Некоторые машины могут иметь дополнительные станции для тиснения рисунков или логотипов на планках жалюзийных дверей и пробивки отверстий для вентиляции или обзора.

- Сборка и фиксация: После того как отдельные компоненты сформированы, их собирают и фиксируют вместе, чтобы создать полноценную жалюзийную дверь. Это может включать в себя соединение планок, крепление направляющих, установку нижних планок и запорных механизмов.

- Отделка и упаковка: Готовые жалюзийные двери проходят все необходимые отделочные процессы, такие как обработка поверхности или покраска, для повышения их долговечности и улучшения внешнего вида. Наконец, двери обычно упаковываются и подготавливаются к транспортировке или установке.

Технические параметры станка для формовки роликовой трубы восьмигранной двери жалюзи

Наш станок для формовки восьмиугольных труб для дверей-жалюзи имеет следующие технические параметры:

- Толщина формовки: 0,4-1,2 оцинкованных рулона

- Скорость формования: 10-15 м/мин (ИСКЛЮЧАЯ ВРЕМЯ ОСТАНОВКИ РЕЗКИ)

- Формовочный ролик: около 20 станций

- Мощность главного двигателя: 7,5 кВт

- Материал ролика: кованая сталь 451ТП5Т, поверхность покрыта хромом

- Материал главного вала: сталь 45#.

- Диаметр основной оси: ¢50 мм

- Гидравлическое давление резки: 10-12 МПа

- Метод резки: гидравлический, резка после профилирования.

- Материал режущего лезвия: закалка Cr12

- Электрическая система управления: вся линия использует управление ПЛК, обрезка до допустимой длины ≤2 мм.

- Аппарат для сварки париков

- система водяного охлаждения

Наш станок для формовки восьмиугольных труб для ворот-жалюзи может эффективно и точно производить высококачественные восьмиугольные трубы, используемые в производстве ворот-жалюзи. В нем используются передовые технологии и функции, такие как гидравлический метод резки, система управления PLC и система водяного охлаждения, для обеспечения высококачественного и эффективного производства. Кроме того, машина оснащена устройством для сварки парок и имеет около 20 станций для формирования роликов, что делает ее надежным и универсальным решением для ваших производственных нужд. Если у вас возникли вопросы или требуется дополнительная информация, пожалуйста, обращайтесь к нам.

Технологическая схема станка для формовки восьмигранной трубы жалюзийной двери

Разматывание – подача Направление – Профилирование – Резка на летучей пиле – Выходной стол – Штамповка

- Размотка: Металлический рулон помещается на гидравлический разматыватель, машина разматывает рулон и подает его в машину.

- Направление подачи: Сервоподатчик перемещает металлический лист через машину и направляет его в процессе формирования валков.

- Формовка валков: Металлический лист проходит через станцию валковой штамповки, где ему придают форму восьмиугольной трубы.

- Резка мухобойкой: После того, как труба сформирована, она проходит через станцию резки мухобойкой, где ее разрезают на отрезки нужной длины.

- Стол выкатки: Готовый продукт собирается в конце машины и помещается на стол выкатки.

- Пробивка: На пробивочной станции в металлическом листе делаются необходимые отверстия и прорези.

Этот процесс контролируется электрической/гидравлической системой, которая обеспечивает точность и эффективность всего производственного процесса. Использование передовых технологий и функций, таких как гидравлические разматыватели, сервоподатчики, пуансоны, роликовые формирователи, серворезки и электрические/гидравлические системы, делает станок для формирования рулонных труб восьмигранной двери ставни надежным и эффективным решением для производства высококачественных рулонных дверей ставни.

Дверь ставни восьмиугольная труба роликовая формовочная машина список

| Серийный номер. | Описание товара | Количество |

| 1 | 3T ручной разматыватель | 1 комплект |

| 2 | кормление | 1 комплект |

| 3 | Основная профилегибочная машина | 1 комплект |

| 4 | Выходная таблица | 1 комплект |

| 5 | Главный привод | 1 комплект |

| 6 | Летучая резка пилой | 1 комплект |

| 7 | Система управления (включая шкаф) | 1 комплект |

| 8 | Штамповочный пресс | 1 комплект |

| 8 | Система водяного охлаждения | 1 комплект |

Наш станок для формовки восьмиугольных труб для роллетных ворот представляет собой комплексное решение для производства высококачественных восьмиугольных труб, используемых в производстве роллетных ворот. Станок включает в себя следующие компоненты:

- Ручной разматыватель 3T: Этот компонент разматывает металлическую катушку и подает ее в машину.

- Направляющая подача: Сервоподатчик перемещает металлический лист через машину и направляет его в процессе формирования валков.

- Главная валковая формовочная машина: Этот компонент придает форму и формирует металлический лист в восьмиугольную трубу с помощью примерно 20 станций формирующих роликов.

- Выходной стол: Готовый продукт собирается в конце машины и помещается на выходной стол.

- Главный привод: Этот компонент обеспечивает мощность для привода процесса формирования валков.

- Резка мухобойкой: После того, как труба сформирована, она проходит через станцию резки мухобойкой, где ее разрезают на отрезки нужной длины.

- Система управления: Она включает в себя систему управления PLC и электрическую/гидравлическую систему, которая обеспечивает точность и эффективность всего производственного процесса.

- Перфорационно-прессовая машина: Этот компонент создает необходимые отверстия и прорези в металлическом листе.

- Система водяного охлаждения: Эта система используется для охлаждения валковой машины во время производственного процесса.

В целом, станок для формовки роллетных ворот из восьмиугольных труб является надежным и эффективным решением для производства высококачественных роллетных ворот. Благодаря своим передовым технологиям и функциям, станок может обеспечить точное и эффективное производство, отвечающее конкретным требованиям вашего приложения.

Чертеж профиля станка для формовки восьмигранной трубы жалюзийной двери

Применения машины для формовки роликовой трубы восьмигранной двери жалюзи

Профилегибочные станки для труб широко используются в производстве различных типов труб. Их можно использовать для изготовления различных форм, в том числе круглых, овальных, прямоугольных и других. В машинах используется ряд валков для формирования нужной формы из куска металла или другого материала. Ролики регулируются для производства различных размеров и форм труб.

Машина для производства восьмиугольных труб для жалюзийных дверей используется для рулонных рулонных ворот. У нас есть трубы 3 размеров: 40 мм, 60 мм, 70 мм, которые можно изготовить на одной машине путем смены кассет.

Восьмиугольная труба жалюзийной двери, машина для формирования роликов круглой трубы для производства восьмиугольной и круглой трубы системы роликовых жалюзи окон и дверей Круглая или восьмиугольная прокатная труба предназначена для намотки роликовых жалюзи, изготавливается в различных формах.

Помимо основного использования в производстве роллетных ворот, станок для формовки роллетных ворот из восьмиугольных труб имеет несколько других применений. Вот несколько примеров различных применений машины:

- Строительство зданий: Восьмиугольные трубы, производимые машиной, могут быть использованы в строительстве для структурной поддержки, например, при строительстве навесов, тентов и солнцезащитных навесов.

- Автомобилестроение и машиностроение: Восьмиугольные трубы, производимые на машине, могут использоваться в автомобильной и машиностроительной промышленности, например, при производстве приводных валов и осей.

- Мебель: Восьмиугольные трубы, произведенные на станке, могут быть использованы в мебельном производстве, например, при изготовлении столов и стульев.

- Оконные жалюзи: Восьмиугольные трубы, произведенные на станке, могут быть использованы в производстве оконных жалюзи, таких как рулонные и венецианские жалюзи.

В целом, станок для формирования рулонов восьмиугольных труб для ворот ставень является универсальным решением для производства высококачественных восьмиугольных труб, которые могут быть использованы в различных областях. Его передовые технологии и функции обеспечивают точное и эффективное производство, что делает его надежным выбором для производителей в различных отраслях промышленности.Наша миссия заключается в предоставлении отличных пользовательских станков и инструментов для профессиональной роликовой формовки восьмигранных труб.Свяжитесь с нами сегодня, чтобы узнать больше о нашем оборудовании и услугах.

Отзывы

Отзывов пока нет.