What is A Pipe Roll Forming Machine?

A pipe roll forming machine is a production line that is used to produce tubes and pipes. It can be used in various industries, such as petrochemical, chemical, and power. The pipe roll forming machine uses a die to form the tube or pipe, and it has a variety of features that make it an efficient tool.

One of the benefits of using a pipe roll forming machine is that it can produce products with accurate dimensions. The die can be adjusted to create different shapes and sizes, which allows for more consistent production. Additionally, the machine can be customized to accommodate different types of materials. This means that it can produce products with specific properties, such as strength and heat resistance.

Another benefit of using a pipe roll forming machine is its speed. The process is relatively fast compared to otherproduction lines, which means that it can handle high-volume production tasks quickly. Additionally, the die does not require much maintenance, so the machine can remain operational for extended periods of time.

What is A Shutter Door Octagonal Pipe Roll Forming Machine ?

Our Shutter Door Octagonal Pipe Roll Forming Machine is an essential piece of equipment in the manufacture of high-quality rolling shutter doors. It is designed to produce octagonal pipes in various materials such as galvanized steel, stainless steel, aluminum, copper, brass, and mild steel, making it ideal for a wide range of applications.

The benefits of using our machine are significant. It enables efficient and accurate production, resulting in a reliable and durable final product. Additionally, the advanced technology and features such as hydraulic uncoilers, servo feeders, punch units, roll formers, servo cutters, and electrical/hydraulic systems ensure the accuracy and speed of the production process.

Furthermore, our machine can increase production capacity and reduce production costs, making it a valuable investment for those in the rolling shutter door industry. With our Shutter Door Octagonal Pipe Roll Forming Machine, you can ensure high-quality and efficient production that meets the specific requirements of your application.

How Does tube roll forming machine Work?

A tube roll forming machine is used to produce cylindrical tubes or pipes with consistent cross-sectional shapes. The process involves feeding a flat strip of metal through a series of rolls, which gradually bend and shape the strip into a tube. Here’s a general overview of how a tube roll forming machine works:

- Material Preparation: The machine begins with a coil or sheet of metal, usually steel or aluminum. The coil is loaded onto an uncoiler, which gradually feeds the strip into the machine.

- Roll Forming Stations: The strip passes through a series of roll forming stations, typically arranged in a linear fashion. Each station consists of a set of rolls, often pairs of top and bottom rolls. The rolls are precisely positioned and designed to gradually shape the strip.

- Forming the Tube Shape: As the strip passes through the roll forming stations, the rolls apply pressure and bending forces to shape the strip into the desired tube shape. The rolls progressively bend the strip, forming the edges together and creating a continuous seam.

- Welding (optional): In some cases, if a continuous welded tube is required, an additional welding station may be incorporated into the machine. This station uses a welding process, such as high-frequency induction welding or laser welding, to join the edges of the strip together, creating a solid seam.

- Sizing and Cutting: After the tube is formed, it passes through sizing stations. These stations use rolls or other mechanisms to adjust the diameter of the tube to its final desired size. The machine may also have a cutting station where the tube is cut to the desired length.

- Finishing and Stacking: Once the tube is cut to length, it goes through any necessary finishing processes, such as deburring or surface treatment. The finished tubes are then typically stacked or collected for further processing or packaging.

It’s important to note that the exact design and operation of a tube roll forming machine can vary depending on the specific manufacturer and the desired tube shape and specifications. Some machines may have additional features or capabilities, such as hole punching or additional forming operations, to meet specific requirements.

what is a shutter door making machine?

A shutter door making machine, also known as a rolling shutter roll forming machine, is designed to produce rolling shutter doors, which are commonly used in commercial and industrial buildings for security purposes. The machine utilizes a roll forming process to shape and fabricate the components of the shutter door. Here’s an overview of how a typical shutter door making machine works:

- Material Loading: The machine begins with loading the raw material, usually a coil of galvanized steel or aluminum, onto an uncoiler. The coil is mounted on a spindle and unwound to provide a continuous strip of material for the forming process.

- Roll Forming: The strip of material is fed into the roll forming stations of the machine. The roll forming stations consist of a series of specially designed rollers that gradually shape the material into the desired profile. These rollers are carefully positioned and spaced to create the necessary folds, curves, and ribs of the shutter door components.

- Profile Shaping: The strip passes through multiple roll forming stations, each responsible for shaping a specific part of the shutter door, such as the slats, guides, and bottom bars. As the strip progresses through the stations, the rolls bend and form the material, transforming it into the required profiles.

- Cutting and Notching: Depending on the design and requirements, the machine may incorporate cutting and notching stations. These stations utilize cutting blades or punches to cut the shutter door components to the desired lengths and create notches or holes for interlocking and assembly.

- Embossing and Hole Punching (Optional): Some machines may have additional stations for embossing patterns or logos onto the shutter door slats and punching holes for ventilation or visibility purposes.

- Assembly and Locking: Once the individual components are formed, they are assembled and locked together to create the complete shutter door. This may involve interlocking the slats, attaching the guides, and incorporating the bottom bars and locking mechanisms.

- Finishing and Packaging: The finished shutter doors go through any necessary finishing processes, such as surface treatment or painting, to enhance their durability and appearance. Finally, the doors are typically packaged and prepared for shipping or installation.

Technical Parameter of Shutter Door Octagonal Pipe Roll Forming Machine

Our Shutter Door Octagonal Pipe Roll Forming Machine has the following technical parameters:

- Forming thickness: 0.4-1.2 galvanized coils

- Forming speed: 10-15M/min (EXCLUDING CUTTING STOP TIME)

- Forming roller: about 20 stations

- Main motor power: 7.5KW

- Roller material: 45# forged steel, surface coated with chrome

- Main shaft material: 45# steel

- Main axis dia.: ¢50mm

- Hydraulic cutting pressure: 10-12Mpa

- Cutting method: hydraulic powered, cutting after roll forming.

- Cutting blade material: Cr12 quenching treatment

- Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

- Wig welding device

- water cooling system

Our Shutter Door Octagonal Pipe Roll Forming Machine can efficiently and accurately produce high-quality octagonal pipes used in the manufacture of rolling shutter doors. It utilizes advanced technology and features such as a hydraulic cutting method, PLC control system, and water cooling system, to ensure high-quality and efficient production. Additionally, the machine includes a wig welding device and features approximately 20 stations for forming rollers, making it a reliable and versatile solution for your production needs. If you have any questions or require further information, please don’t hesitate to contact us.

Flow Chart of Shutter Door Octagonal Pipe Roll Forming Machine

Uncoiling – feed Guiding–Roll forming –fly saw cutting –Run-out table-Punching

- Uncoiling: The metal coil is placed on the hydraulic uncoiler and the machine unwinds the coil and feeds it into the machine.

- Feed Guiding: The servo feeder moves the metal sheet through the machine and guides it through the roll forming process.

- Roll Forming: The metal sheet passes through the roll forming station where it is shaped and formed into an octagonal pipe.

- Fly Saw Cutting: Once the pipe is formed, it passes through a fly saw cutting station where it is cut to the desired length.

- Run-out table: The finished product is then collected at the end of the machine and placed on a run-out table.

- Punching: At the punching station, the necessary holes and cuts are made in the metal sheet.

This process is controlled by the electrical/hydraulic system which ensures accuracy and efficiency throughout the production process. The use of advanced technology and features such as hydraulic uncoilers, servo feeders, punch units, roll formers, servo cutters, and electrical/hydraulic systems makes Shutter Door Octagonal Pipe Roll Forming Machine a reliable and efficient solution for the manufacture of high-quality rolling shutter doors.

Shutter Door Octagonal Pipe Roll Forming Machine List

| Serial No. | Commodity & Description | Quantity |

| 1 | 3T manual uncoiler | 1 set |

| 2 | feeding guiding | 1 set |

| 3 | Main roll forming machine | 1 set |

| 4 | Output table | 1 set |

| 5 | Main drive | 1 set |

| 6 | Fly saw cutting | 1 set |

| 7 | Controlling system (including cabinet) | 1 set |

| 8 | Punching press machine | 1 set |

| 8 | Water cooling system | 1 set |

Our Shutter Door Octagonal Pipe Roll Forming Machine is a complete solution for the production of high-quality octagonal pipes used in the manufacture of rolling shutter doors. The machine includes the following components:

- 3T Manual Uncoiler: This component unwinds the metal coil and feeds it into the machine.

- Feeding Guiding: The servo feeder moves the metal sheet through the machine and guides it through the roll forming process.

- Main Roll Forming Machine: This component shapes and forms the metal sheet into an octagonal pipe using approximately 20 stations of forming rollers.

- Output Table: The finished product is collected at the end of the machine and placed on the output table.

- Main Drive: This component provides the power to drive the roll forming process.

- Fly Saw Cutting: Once the pipe is formed, it passes through a fly saw cutting station where it is cut to the desired length.

- Controlling System: This includes a PLC control system and an electrical/hydraulic system which ensures accuracy and efficiency throughout the production process.

- Punching Press Machine: This component creates the necessary holes and cuts in the metal sheet.

- Water Cooling System: This system is used to cool down the roll forming machine during the production process.

Overall, the Shutter Door Octagonal Pipe Roll Forming Machine is a reliable and efficient solution for the manufacture of high-quality rolling shutter doors. With its advanced technology and features, the machine can ensure accurate and efficient production that meets the specific requirements of your application.

Profile Drawing of Shutter Door Octagonal Pipe Roll Forming Machine

Applications of the Shutter Door Octagonal Pipe Roll Forming Machine

The pipe roll forming machines are widely used in the manufacturing of various types of pipes and tubes. They can be used to produce a variety of shapes, including round, oval, rectangular, and others. The machines use a series of rolls to form the desired shape from a piece of metal or other material. The rollers are adjustable to produce a variety of different pipe sizes and shapes.

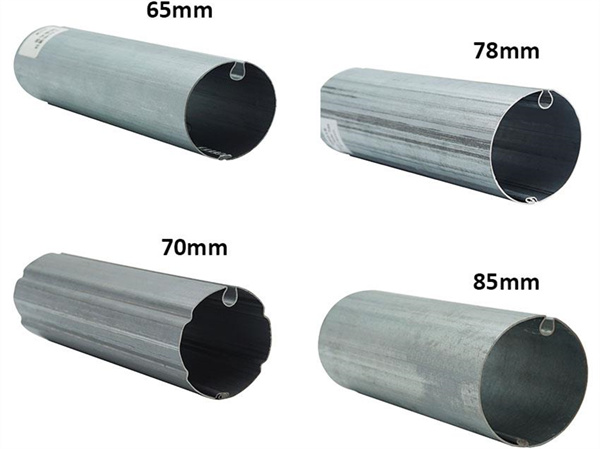

Shutter door octagonal pipe roll forming machine is used for the rolling shutter door reels, the pipe We have 3 sizes, 40mm, 60mm, 70mm, which can be made in one machine by changing cassettes.

Shutter door octagonal pipe roll forming machine, Round Tube Roll Forming machine for manufacturing Octagonal & round Tube of Rolling Shutter Windows and Doors system The round or octagonal rolling tube is for winding up the rolling shutter, made in various shapes.

In addition to its primary use in the manufacture of rolling shutter doors, the Shutter Door Octagonal Pipe Roll Forming Machine has several other applications. Here are some examples of different applications of the machine:

- Building Construction: The octagonal pipes produced by the machine can be used in building construction for structural support, such as in the construction of canopies, awnings, and sunshades.

- Automotive and Machinery: The octagonal pipes produced by the machine can be used in automotive and machinery applications, such as in the manufacture of drive shafts and axles.

- Furniture: The octagonal pipes produced by the machine can be used in furniture applications, such as in the manufacture of tables and chairs.

- Window Blinds: The octagonal pipes produced by the machine can be used in the manufacture of window blinds, such as roller blinds and Venetian blinds.

Overall, the Shutter Door Octagonal Pipe Roll Forming Machine is a versatile solution for the production of high-quality octagonal pipes that can be used in a variety of applications. Its advanced technology and features ensure accurate and efficient production, making it a reliable choice for manufacturers in various industries.Our mission is to provide excellent custom octagonal rolling tube roll forming machines and tools for professional rolling shutter machines.Contact us today to learn more about our equipment and services.

Reviews

There are no reviews yet.