What is A metal shutter door roll forming machine?

The metal shutter door roll forming machine is a specialized piece of equipment designed for manufacturing metal shutter door roll forming machine. It utilizes advanced roll forming technology to shape metal sheets into the desired profile for the rolling shutter door. The machine typically includes a decoiler to feed the metal sheet, a roll former with a series of rollers that gradually shape the metal, and a cutter to cut the metal to the desired length.

Our metal shutter door roll forming machine is designed with precision and efficiency in mind, allowing for high-quality production at a fast pace. It is equipped with advanced control systems to ensure accuracy and consistency in the shaping process. The resulting product is a strong and durable rolling shutter door that can provide security, insulation, and other benefits for commercial and industrial applications.

Our metal shutter door roll forming machine can accommodate a variety of metal sheet thicknesses and widths, making it highly versatile and adaptable to different manufacturing needs. Additionally, we offer customization options to tailor the machine to specific requirements, ensuring optimal performance and productivity.

How Does shutter door roll forming machine work?

A shutter door roll forming machine works by continuously bending and shaping a long strip of metal into the desired profile of a shutter door. Here’s a step-by-step explanation of how the machine typically operates:

- Material Feeding: The metal strip, usually in coil form, is loaded onto a decoiler at the beginning of the roll forming line. The decoiler unwinds the strip, allowing it to move smoothly through the machine.

- Guiding and Leveling: The strip passes through a series of guiding and leveling devices to ensure it remains in the correct position and is properly aligned as it enters the roll forming section.

- Roll Forming: The heart of the machine is the roll forming section. This section consists of a series of rollers that are strategically arranged to gradually shape the metal strip. Each set of rollers performs a specific bending operation, incrementally transforming the strip into the desired profile of the shutter door. The rollers are typically driven by electric motors and can be adjusted to achieve the precise dimensions and shapes required.

- Cutting: Once the metal strip has been fully formed, a cutting mechanism is employed to separate the formed shutter doors from the remaining strip. This can be done using various cutting techniques, such as shearing, punching, or sawing, depending on the specific design and requirements.

- Additional Operations: Depending on the design and specifications of the shutter door, the machine may include additional stations for performing operations such as punching holes, embossing patterns or logos, adding locks or hinges, and applying protective coatings or finishes. These stations are often integrated into the roll forming line, allowing for a continuous and automated production process.

- Collection and Stacking: After the shutter doors have been cut and any additional operations have been completed, they are collected and stacked for further processing or packaging. This can be done using automated systems or manual handling, depending on the size and weight of the finished products.

Throughout the entire process, the machine is typically controlled by a computerized system that ensures precise and consistent shaping of the metal strip. Sensors and feedback mechanisms may be employed to monitor the production parameters and make necessary adjustments to maintain accuracy and quality.

By utilizing a shutter door roll forming machine, manufacturers can efficiently produce high-quality shutter doors in a variety of sizes and designs, catering to the specific needs of their customers.

The Technique Data of Metal Rolling Up Shutter Door Roll Forming Machine

- Materials to form Metal Rolling Shutter Door Machine: 0.7-1.2mm galvanized coils Feeding width: 184mm

- Forming steps: about 12 steps

- Material of rollers: GCr15 steel, precision-machined high frequency quenching HRC58-62 diameter of rollers: 150

- Material of main shaft : 45# high quality steel

- Chain material: 45# steel high frequency quenching, circular pitch:38.1 number of teeth: 13

- Cutting: hydraulic cutting quenching HRC58-62

- Electronic control: PLC control Panasonic Brand

- Dimension of machine: 4500mmX500mmX800mm

- Working speed:12-15m/min

- Drive system: chain drive

- Main motor power: 7.5KW

The Metal Rolling Up Shutter Door Roll Forming Machine is designed to form galvanized coils with a thickness range of 0.7-1.2mm into rolling shutter doors. The feeding width of the metal sheet is 184mm, and the machine has about 12 forming steps.

The rollers of the machine are made of GCr15 steel and are precision-machined with high-frequency quenching, ensuring a hardness of HRC58-62. The diameter of the rollers is 150mm, providing efficient and consistent shaping.

The main shaft of the machine is made of 45# high-quality steel, and the chain material is made of 45# steel that has undergone high-frequency quenching. The circular pitch of the chain is 38.1, and the number of teeth is 13, ensuring smooth and stable operation.

The machine is equipped with hydraulic cutting that has undergone quenching with HRC58-62 hardness, ensuring efficient and precise cutting. The electronic control system is PLC control from the reputable brand Panasonic.

The dimensions of the machine are 4500mm X 500mm X 800mm, and the working speed is 12-15m/min. The drive system is chain drive, providing reliable and efficient power transmission. The main motor power of the machine is 7.5KW, making it a powerful and capable machine for rolling shutter door production.

We are committed to providing our buyers with detailed and accurate information about our Metal Rolling Up Shutter Door Roll Forming Machine, and we welcome any further questions or inquiries.

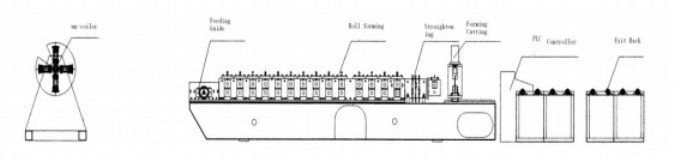

Working Flow of Metal Rolling Up Shutter Door Roll Forming Machine

De-coiler—→level device—→main roll forming machine—→ hydraulic cutting—→ run out table

The Working Flow of the Metal Rolling Up Shutter Door Roll Forming Machine can be described as follows:

- Decoiling: The metal coil is loaded onto the decoiler and unrolled, providing a continuous supply of material for the machine.

- Guiding and Feeding: The metal sheet is guided and fed into the roll forming machine through a series of rollers that shape it into the desired profile.

- Roll Forming: The metal sheet is passed through a series of rollers that gradually shape it into the desired profile for the rolling shutter door. The rollers’ shape determines the final shape of the metal sheet, and the machine may have multiple sets of rollers to create complex profiles or accommodate different metal sheet widths.

- Cutting: The shaped metal sheet is cut to the desired length using a hydraulic cutting system that has undergone quenching with HRC58-62 hardness, ensuring efficient and precise cutting.

- Collecting: The finished product, a rolling shutter door with a strong and durable metal profile, is collected at the end of the machine.

Throughout the process, the machine’s advanced control systems monitor and adjust the speed and pressure of the rollers and cutter to ensure accuracy and consistency in the shaping process.

Parts of Metal Rolling Up Shutter Door Roll Forming Machine

| Name | Quantity (set) |

| De-coiler | 1 set |

| Level device | 1 set |

| Hydraulic cutting machine | 1 set |

| Main roll forming machine | 1 set |

| Run out table | 2 sets |

| Control panel | 1 set |

The Metal Rolling Up Shutter Door Roll Forming Machine consists of the following parts:

- De-coiler: This is the first component of the machine and is used to hold the metal coil that will be fed into the roll forming machine.

- Level device: This device is used to ensure that the metal sheet is level and straight before it is fed into the roll forming machine. This helps to prevent any distortion or bending in the final product.

- Hydraulic cutting machine: This component of the machine is used to cut the metal sheet to the desired length once it has been formed into the correct profile by the roll forming machine.

- Main roll forming machine: This is the core component of the machine and is responsible for gradually shaping the metal sheet into the desired profile for the rolling shutter door. It typically includes a series of rollers that bend and shape the metal sheet as it passes through.

- Run out table: This component of the machine provides support for the finished product as it exits the roll forming machine. It typically consists of two sets of tables that help to ensure that the finished product remains level and straight.

- Control panel: This component of the machine is used to control and monitor the operation of the entire system. It typically includes a PLC control system from a reputable brand, such as Panasonic.

Overall, our Metal Rolling Up Shutter Door Roll Forming Machine is a complex system that includes several key components, each of which plays a crucial role in the overall operation of the machine. By working together, these components allow for efficient and precise production of high-quality rolling shutter doors made from metal.

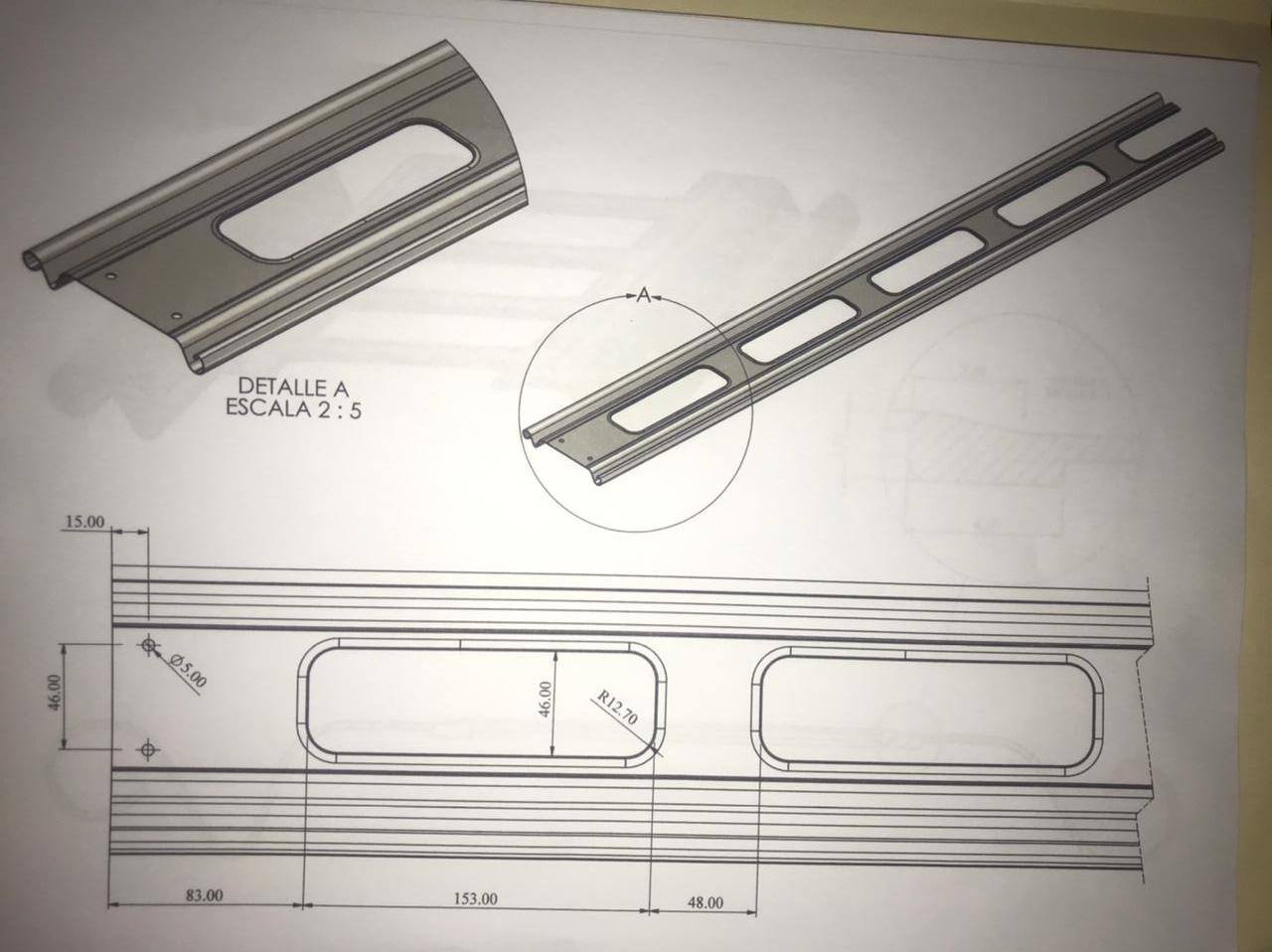

Profile Drawing of Metal Rolling Up Shutter Door Roll Forming Machine

Application of metal shutter door roll forming machine

The metal shutter door roll forming machine is a versatile machine widely used in the manufacturing industry to produce rolling shutter doors made from metal. These doors have numerous applications, including providing a strong and durable barrier against unauthorized access in commercial and industrial settings such as storefronts, warehouses, factories, and garages.

Rolling shutter doors also offer an added layer of security and protection against theft, vandalism, and natural disasters such as storms and hurricanes. They can be insulated to provide thermal insulation, reducing energy costs for buildings that require temperature control, such as food storage facilities or cold rooms. Additionally, rolling shutter doors can reduce noise levels in buildings located in noisy environments, such as near airports or highways.

Our metal shutter door roll forming machine is highly versatile and can produce a variety of rolling shutter door profiles, including those with insulation or other specialized features. It is equipped with advanced control systems to ensure accuracy and consistency in the shaping process, resulting in high-quality products that meet the needs of various customers.

Details of Each Metal Rolling Up Shutter Door Roll Forming Machine Composition

1.3 tons passive decoiler

- 3 tons passive decoiler

- Coil inner Diameter: ¢460-520mm

The machine comes with either a 1.3 ton or a 3 ton passive decoiler, which is used to hold the metal coil that will be fed into the roll forming machine. The coil inner diameter should be between ¢460-520mm.

2. Level Device

The level device is used to ensure that the metal sheet is level and straight before it is fed into the roll forming machine. This helps to prevent any distortion or bending in the final product.

3. Hydraulic Cutting

- Cutting after forming: Cut the sheet after roll forming to required length

- Cutting motion: The main machine automatically stops, and the cutting will take place. After the cutting, the main machine will automatically start.

- Material of blade: CR12mov with heat treatment

- Length measuring: Automatic length measuring

- Tolerance of length: 10m+/- 2mm

The hydraulic cutting system is responsible for cutting the metal sheet to the desired length once it has been formed into the correct profile by the roll forming machine. The cutting motion is automatic and occurs after the main machine stops. The blade is made of CR12mov with heat treatment. The length is automatically measured, and the tolerance of length is 10m+/- 2mm.

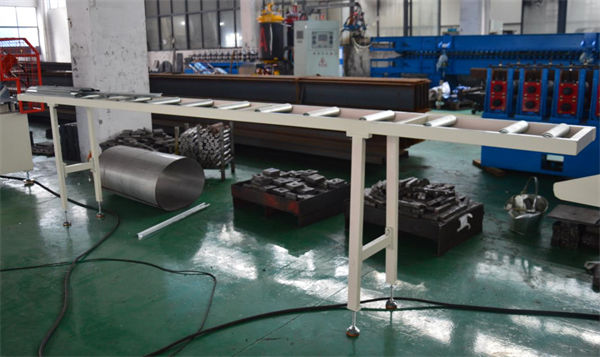

4. Out Table

- Length :6 meters

- Quantity: 1 unit

The out table provides support for the finished product as it exits the roll forming machine. The length is 6 meters, and there is one unit.

5. Control Box: Delta Brand

- Power supplier: 380V, 50 Hz, 3Phase (adjusted with the requestment)

- Length & quantity measurement automatically;

- Length & quantity controlled by PLC,

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- The language in the touch screen: English and Chinese

- Unit of length: millimeter (switched on the control panel)

The control box is responsible for controlling and monitoring the operation of the entire system. It is equipped with a Delta Brand power supplier that is adjustable to the required specifications. The length and quantity are automatically measured and controlled by a PLC system, and the length inaccuracy can be amended easily. The control panel includes a button-type switch and touch screen, and the language on the touch screen can be switched between English and Chinese. The unit of length is millimeters.

Overall, our Metal Rolling Up Shutter Door Roll Forming Machine is a complex system that includes several key components, each of which plays a crucial role in the overall operation of the machine. By working together, these components allow for efficient and precise production of high-quality rolling shutter doors made from metal.

best 5 shutter door roll forming machine manufacturers in China

- Sussman Machinery(Wuxi)Co., Ltd. export to more than 100 countries, and our customers are around the world, especially Australia, South America, Europe, India, Middle East, Northern Europe and North Africa. Furthermore, we wish to build the best machine for customers, our core values are “Quality, Efficiency, Credibility & Integrity”, which can firmly and solidly support us to go far.

- Hangzhou Zhongyuan Machinery Factory: They have been producing roll forming machines since 2003 and offer a wide range of machinery, including shutter door roll forming machines.

- Liming Stamping Form Machine Co., Ltd: With over 20 years of experience, Liming is a reputable manufacturer specializing in roll forming machines, including those for shutter doors.

- Botou Golden Integrity Roll Forming Machine Co., Ltd: Established in 1993, Golden Integrity is a well-known manufacturer of roll forming machines, including those for shutter doors, with a strong emphasis on quality and customer satisfaction.

- Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd: They have been manufacturing roll forming machines for more than 20 years and offer a diverse range of machines, including shutter door roll forming machines.

Reviews

There are no reviews yet.