| Machine list | 3 ton passive de-coiler | 1 set | |

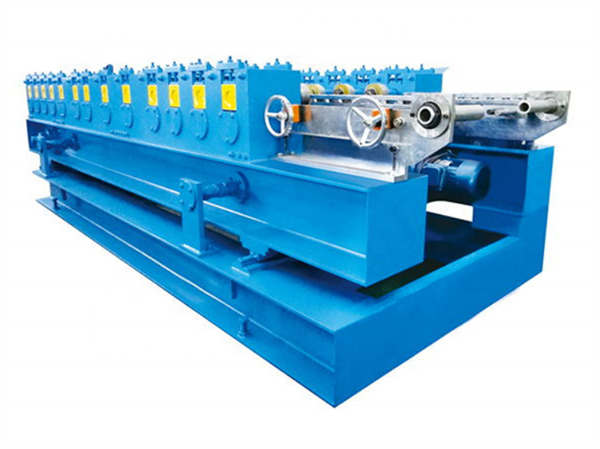

| Main roll forming machine | 1 set | ||

| PLC Control box | 1 unit | ||

| Hydraulic station | 1 unit | ||

| Out table | 2 units | ||

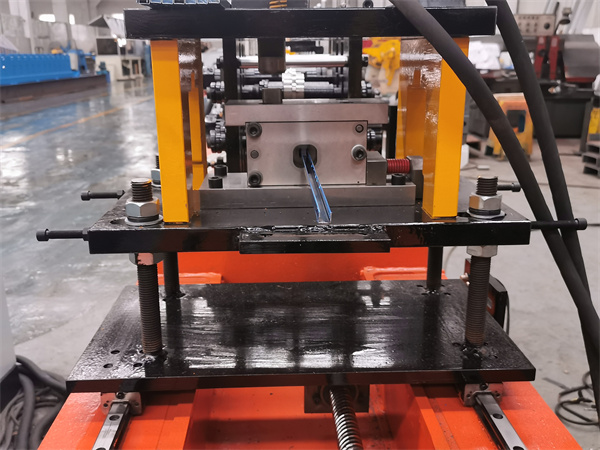

| Hydraulic Servo following cutting | 1 unit | ||

| Safety cover | 1 unit | ||

| Subtotal FOB Shanghai | USD39,500 | ||

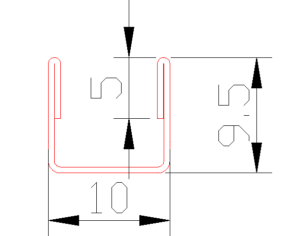

Profile of Stainless U Channel for Glass Window Supporter Machine

Technical data

Technological process:

Decoiler—Rollforming—HydraulicServo followingCutting—Products collecting

The external of machine:

| Items | Specifications | Remarks | |

| Material of coil | Material Thickness | 0.6mm Stainless Steel | |

| Forming system | Rolling Speed | About 30m/min line speed | |

| Roller Stations | About 18 stations | ||

| Roller Material | Gcr15 Steel with quenching 60mm shaft

|

||

| Maim Motor Power | 5.5 kw motor | ||

| hydraulic station Power | 4 kw | ||

| Cutting

system |

Material Of Cutting | CR12 with quench treatment | |

| Hardness | HRC58-62 | ||

| Tolerance | +-1.5mm | ||

| Servo motor | 1.8kw Delta | ||

| Electrical control system | Electric Source | 380V, 50HZ,3 phase

Also can satisfy Customer’s require |

|

| Control System | PLC control system | ||

| Weight | About 3.5 tons | ||

| Way Of Drive | 1 inch single chain | ||

| Size of machine | Length 5500mm* Width 600mm* Height 1000m |

Spare parts

Hydraulic station

Out table

Cutting device

3 ton passive de-coiler

PLC control box

Spare parts pictures just for reference

what is stainless steel roll forming machine?

A stainless steel roll forming machine is a specialized industrial machine used to manufacture stainless steel profiles or components through a process called roll forming. Roll forming is a continuous bending operation in which a long strip of stainless steel is passed through a series of rollers, gradually shaping it into the desired profile.

The stainless steel roll forming machine consists of several key components:

- Uncoiler: This component holds the stainless steel coil and feeds it into the machine for processing.

- Leveler: It straightens the incoming strip and removes any coil set or camber to ensure a flat starting material.

- Rollers: The heart of the roll forming machine, the rollers are designed in sets and gradually shape the stainless steel strip into the desired profile. Each set of rollers performs a specific bending or forming operation.

- Drive system: It powers the rollers and controls their rotation speed to maintain consistent forming.

- Cut-off system: At the end of the roll forming process, the machine may have a cut-off system that trims the formed stainless steel profile to the desired length.

- Control panel: It allows operators to adjust various parameters such as roller positions, speed, and cut-off length to achieve the desired results.

Stainless steel roll forming machines are commonly used in industries such as construction, automotive, appliances, and manufacturing, where stainless steel profiles with specific shapes and dimensions are required. These machines offer high efficiency, precision, and repeatability in producing stainless steel components for various applications.

application of channel roll forming machine

A channel roll forming machine is specifically designed to produce channels, which are C-shaped or U-shaped profiles commonly used in construction, infrastructure, and various industries. The applications of channel roll forming machines are diverse and include:

- Construction industry: Channels produced by roll forming machines are widely used in construction projects for various applications, such as structural supports, roof and wall framing, purlins, joists, and floor decking. They provide strength, rigidity, and support to the building structure.

- Electrical and HVAC industries: Channel profiles are used in the electrical and HVAC (heating, ventilation, and air conditioning) industries to mount and support electrical wiring, conduits, cable trays, air ducts, and other components. The precise dimensions and consistent quality of channels produced by roll forming machines ensure compatibility and ease of installation.

- Shelving and storage systems: Channel profiles are employed in the manufacturing of shelving and storage systems for warehouses, retail stores, and industrial facilities. These channels provide the structural framework for the shelves, racks, and storage units, allowing for efficient organization and storage of goods and materials.

- Material handling and conveyance: Channels are used in conveyor systems, material handling equipment, and transportation systems. They serve as guides, supports, or frames for moving components, conveying materials, and facilitating automated processes.

- Automotive and transportation industry: Channel profiles find applications in the automotive and transportation industry for various purposes, such as frame components, suspension parts, roof racks, and cargo carriers. The strength and durability of roll-formed channels make them suitable for withstanding the demands of the automotive sector.

- Solar energy systems: Channels are utilized in the construction of solar energy systems, including mounting structures for solar panels. These channels provide the necessary support and stability to secure solar panels in place, ensuring optimum exposure to sunlight for efficient energy generation.

- Agricultural equipment: Channel profiles are utilized in the fabrication of agricultural machinery and equipment, including frames for tractors, implements, and storage systems for agricultural products.

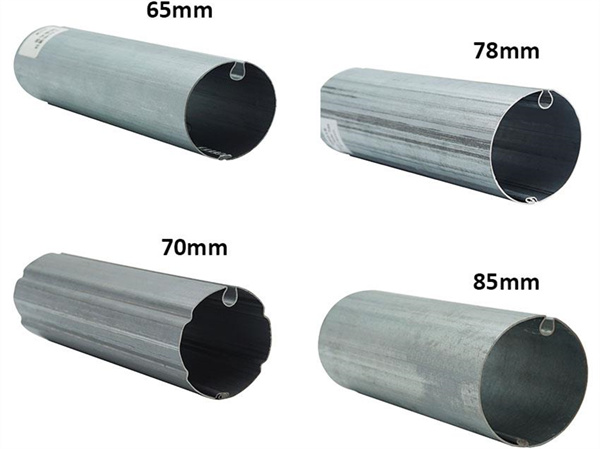

The versatility of channel roll forming machines allows for the production of channels with various dimensions, materials (including stainless steel, galvanized steel, or aluminum), and customized features to meet specific application requirements in different industries.

how to choose strut channel roll forming machine?

Choosing the right strut channel roll forming machine requires careful consideration of several factors to ensure that the machine meets your specific requirements. Here are some key factors to consider when selecting a strut channel roll forming machine:

- Profile specifications: Determine the specific dimensions, shape, and features of the strut channel profiles you need to produce. Consider the width, height, thickness, and hole patterns required for your channels. Ensure that the machine you choose can accommodate the desired profile specifications.

- Material compatibility: Consider the type of material you will be using for strut channels, such as steel, stainless steel, or aluminum. Ensure that the roll forming machine is capable of processing the chosen material and has the appropriate strength and durability to handle it effectively.

- Production capacity: Evaluate your production requirements in terms of the desired output and production volume. Consider the speed, efficiency, and productivity of the machine. Look for a machine that can meet your production targets and can handle the expected workload without compromising quality.

- Machine flexibility: Assess the machine’s ability to produce a variety of strut channel profiles. Look for a machine that offers flexibility in terms of easily adjusting the roller sets and tooling to accommodate different profile shapes and dimensions.

- Quality and precision: Ensure that the roll forming machine is built with high-quality components and precision engineering to produce accurate and consistent strut channels. Look for machines with advanced control systems and reliable cutting mechanisms for precise length and hole punching.

- Operator-friendly features: Consider the ease of use and operator-friendly features of the machine. Look for machines that have user-friendly control panels, intuitive interface, and quick setup/changeover capabilities. Training and support from the manufacturer should also be available to ensure efficient operation and maintenance.

- Manufacturer reputation and support: Research the reputation and reliability of the machine manufacturer. Check for customer reviews and testimonials to gauge their track record and after-sales support. Ensure that the manufacturer provides technical support, spare parts availability, and warranty coverage for the machine.

- Cost and budget: Consider your budget constraints while evaluating the overall value and cost-effectiveness of the machine. Compare prices, features, and capabilities across different manufacturers to make an informed decision.

By considering these factors and conducting thorough research, you can select a strut channel roll forming machine that aligns with your specific requirements, production capacity, and budget, ensuring smooth and efficient production of high-quality strut channels.

Reviews

There are no reviews yet.