Specification of the Windows & Doors Pu Foam Insulated Shutters Slat Roll Forming Machine

- Windows & Doors Pu Foam Insulated Shutters Slat Roll Forming Machine parameters:

- Model (for windows): 37mm; 39mm; 42mm; 45mm (flat); 55mm

- Model (for doors): 77mm; 90mm; 95mm; 98mm; 100mm

Specification for Machine

- Motor power: total 5.5 KW; 380V; 50/60HZ China brand

- Mixing head with one spare is included

- Mixing pump quantity: 8g/Second

- Density: 70~80 Kg/m3

- Mixing type: mechanical & automatic

- Washing: Automatic

- Tank volume: 50 KG / tank. Both Poly and ISO

- Brand of Windows & Doors Pu Foam Insulated Shutters Slat Roll Forming Machine: GREAT WALL.

Working Flow

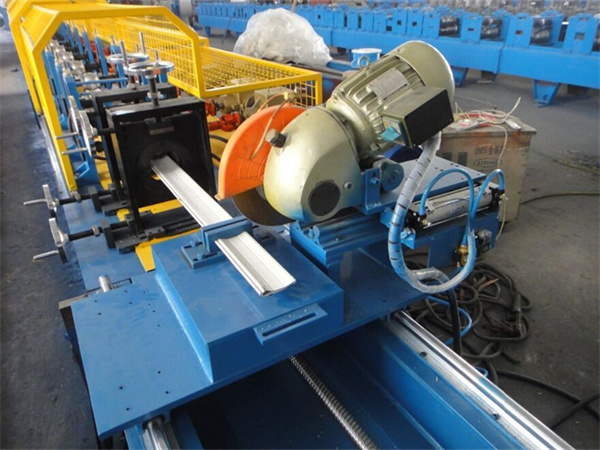

Decoiler—feeding device—main forming—PU injection—straigh ten device——Flysaw Cutting —run out table

Windows & Doors Pu Foam Insulated Shutters Slat Roll Forming Machine List

| 1 | De-coiler | 1 set |

| 2 | Guide Feeding device | 1 set |

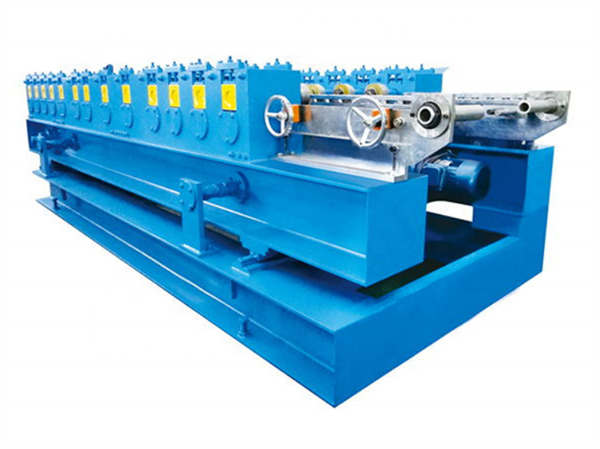

| 3 | main forming machine | 1 set |

| 4 | Foaming machine (just foamed one owned) | 1 set |

| 5 | Straighten device | 1 set |

| 6 | flying saw cutting machine | 1 set |

| 7 | finished products table | 1 set |

| 8 | PLC control system | 1 set |

| 9 | Spare Parts And Tools | 1 set |

Application of the Windows & Doors Pu Foam Insulated Shutters Slat Roll Forming Machine

Roller shutter door is a type of door or window consisting of many horizontal strip (or sometimes bars or web systems) hinged together. The door is raised to open it and lowered to close it. On large doors, the action may be motorized.

It provides protection against wind and rain. In shutter form, it is used in front of a window and protects the window from vandalism and burglary attempts.

Windows & Doors Pu Foam Insulated Shutters Slat Roll Forming Machine has many applications, including doors for vans, garages, kitchens, schools, prisons and warehouses.

In some parts of the world, roller shutters door are subsidized by local governments due to the inherent security benefits. In areas that are frequently exposed to inclement weather, roller shutters are used as a method of insulation and can protect windows against hail damage.

what is roller shutter slat roll forming machine

A roller shutter slat roll forming machine is a specialized industrial machine used for manufacturing roller shutter slats or profiles. Roller shutters are commonly used in commercial and residential buildings for security, insulation, and privacy purposes. The roll forming machine is designed to produce these slats efficiently and precisely.

The machine operates by continuously feeding a metal coil strip into a series of rollers that gradually shape the material into the desired profile. The rollers are strategically positioned to gradually bend, fold, and shape the metal strip into the specific cross-sectional profile of the roller shutter slat. The process is automated and controlled by a computer system, ensuring consistency and accuracy in the production.

The roll forming machine can produce slats of various dimensions and profiles, depending on the specific requirements of the roller shutter system. The resulting slats are typically made from materials like galvanized steel, aluminum, or stainless steel, which offer durability and resistance to corrosion.

After the slats are formed, they can be cut to the desired length and undergo additional processes such as perforation, embossing, or coating, depending on the design and functionality of the roller shutter system.

Overall, a roller shutter slat roll forming machine is a specialized manufacturing equipment used in the production of roller shutter slats, enabling efficient and precise fabrication of these components for various applications.

application of laminated pe foam roll forming machine

A laminated PE foam roll forming machine is a specialized industrial machine used for manufacturing laminated polyethylene (PE) foam rolls. These foam rolls find various applications in industries such as packaging, insulation, construction, automotive, and more. Here are some common applications of laminated PE foam rolls:

- Packaging: Laminated PE foam rolls are widely used for packaging fragile and delicate items. The foam provides cushioning and protection, preventing damage during transportation and handling. It is commonly used in the electronics, glassware, furniture, and automotive industries.

- Insulation: The excellent thermal insulation properties of laminated PE foam make it suitable for insulating buildings, refrigeration units, HVAC systems, and pipes. It helps in reducing heat transfer and maintaining temperature stability.

- Soundproofing: Laminated PE foam rolls can be used for soundproofing applications. The foam’s cellular structure helps absorb and dampen sound waves, making it useful for noise reduction in buildings, studios, theaters, and automotive interiors.

- Automotive Industry: Laminated PE foam rolls are utilized in the automotive industry for various purposes. They can be used as gaskets, seals, and vibration dampeners to enhance comfort, reduce noise, and improve the overall performance of vehicles.

- Medical and Healthcare: Laminated PE foam rolls are used in the healthcare industry for cushioning and padding purposes. They can be found in medical devices, orthopedic supports, prosthetics, and other applications requiring shock absorption and pressure distribution.

- Sports and Leisure: PE foam rolls are used in sports and leisure products like yoga mats, exercise equipment padding, camping mats, and flotation devices. The foam provides cushioning, impact resistance, and comfort.

- Construction: Laminated PE foam rolls are used in the construction industry as underlayment for flooring, wall insulation, and roofing insulation. The foam helps in reducing noise transmission, providing thermal insulation, and improving energy efficiency.

The laminated PE foam roll forming machine allows for the efficient and precise production of these rolls by laminating the PE foam with various materials like adhesive films, aluminum foil, or other substrates to enhance its properties and enable specific applications.

advantages of oem shutter roll forming machine

- Customization: OEM machines are designed and built specifically for the production of roller shutters. They can be customized to meet the specific requirements of the manufacturer, allowing for precise control over the dimensions, profiles, and features of the shutter components. This customization capability enables manufacturers to produce a wide range of shutter designs and sizes to cater to diverse customer needs.

- High Efficiency: OEM machines are engineered for high-speed and continuous production, resulting in increased efficiency and productivity. These machines are optimized for roll forming the slats or profiles at a rapid pace, reducing production time and labor costs.

- Consistent Quality: OEM machines are designed with precision and incorporate advanced automation and control systems. This ensures consistent and accurate production of roller shutter components, maintaining high quality throughout the manufacturing process. The use of OEM machines minimizes variations and defects, resulting in reliable and durable products.

- Easy Operation and Maintenance: OEM machines are designed for user-friendly operation, with intuitive controls and interfaces. They are equipped with automated systems for coil feeding, roll forming, cutting, and stacking, reducing the need for manual intervention. Additionally, OEM manufacturers typically provide comprehensive documentation and support for maintenance and troubleshooting, ensuring smooth operation and minimal downtime.

- Versatility: OEM shutter roll forming machines can be versatile, allowing for the production of various types of roller shutters, including different profiles, sizes, and materials. They can accommodate different metal coil thicknesses, widths, and lengths, enabling manufacturers to offer a wide range of shutter options to their customers.

- Cost-Effectiveness: With high efficiency, consistent quality, and easy operation, OEM machines offer cost-effective production solutions. The reduced labor costs, minimal material waste, and improved productivity contribute to overall cost savings for manufacturers.

- Long-Term Support: OEM manufacturers typically provide long-term support, including spare parts availability, technical assistance, and upgrades. This ensures that the shutter roll forming machine remains operational and productive for an extended period, maximizing the return on investment for the manufacturer.

Reviews

There are no reviews yet.