You might be wondering if investing in a corrugated roll forming machine for sale is the right choice for your business, especially considering it’s an expensive piece of machinery. Before deciding whether or not you should buy a corrugated roll forming machine, check out the three reasons below to decide if this investment is worth it for your business.

What is a Corrugated Roll Forming Machine?

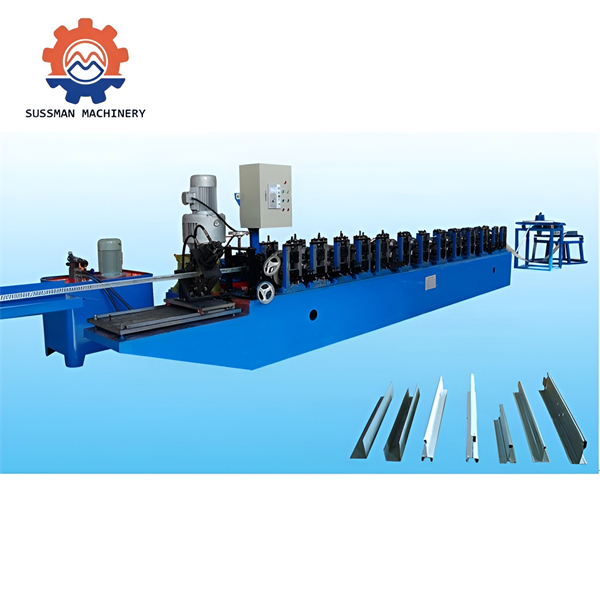

A corrugated roll forming machine is an important piece of equipment for producing precision corrugated products. It forms the individual, pre-cut pieces of cardboard into a variety of shapes and sizes using heat and pressure. The machine is especially useful for producing boxes, packaging materials, and other structural products.

A corrugated roll forming machine for sale is a great way to produce products quickly and easily. They can be used to create a variety of items, including boxes, trays, and even fabric rolls. The machines use corrugated paper to form the desired shape, which makes them an ideal option for products that need to be quickly assembled or shipped. Additionally, they’re relatively easy to operate and maintain, making them a good choice for businesses with limited resources.

3 Reasons to Buy a Corrugated Roll Forming Machine for sale

When looking to purchase a corrugated roll forming machine for sale, there are many benefits to taking into account. Owning one can save you time and money, while also providing you with the ability to produce high-quality products quickly and efficiently. Here are several reasons why purchasing a corrugated roll forming machine is a great idea:

Time-saving: One of the main benefits of owning a corrugated roll forming machine for sale is that it can save you time. Rather than having to manually form products by hand, using a rolling machine allows you to quickly and easily create customized items. This is especially beneficial if you have a large quantity of products that need to be formed in a hurry.

Quality control: Another benefit of using a rolling machine for product formation is that it ensures high quality results. By automatically pressing the material against the dielectric surface, machines like these ensure consistent thicknesses across all pieces produced. This means less variation in product appearance and overall quality – something that’s critical when producing products such as packaging or furniture components.

Speed and efficiency: Finally, using a corrugated roll forming machine for sale allows you to produce products quickly and efficiently. By automating the process, you can save valuable time while still ensuring high-quality results. This makes it an ideal choice for businesses that need to meet tight deadlines – such as those in the manufacturing or packaging industries.

-

Joint Rack steel beam roll forming machine

Joint Rack steel beam roll forming machine -

Rockwool Sandwich Panel Line

Rockwool Sandwich Panel Line -

shelf panel roll forming machine for metal steel racking back

shelf panel roll forming machine for metal steel racking back -

6 Sides Upright Racking Step Beam Welding Machine

6 Sides Upright Racking Step Beam Welding Machine -

Laser welding racking step beam roll forming machine

Laser welding racking step beam roll forming machine -

box beam roll forming machine for Steel Shelf racking

box beam roll forming machine for Steel Shelf racking -

Upright racking roll forming machine for Heavy Duty Column

Upright racking roll forming machine for Heavy Duty Column -

Polyurethane Foam PU Roof and Wall Sandwich Panel Production Line

Polyurethane Foam PU Roof and Wall Sandwich Panel Production Line -

High speed Guard Railway Crash barrier roll forming machine

High speed Guard Railway Crash barrier roll forming machine

How to Buy the Right Corrugated Roll Forming Machine for sale for Your Business?

When it comes to buying a corrugated roll forming machine for sale, there are a few things you need to keep in mind. First and foremost, you will need to decide what type of material you will be forming. Additionally, you will need to factor in the machine’s size and capabilities. Once you have all of these factors figured out, it is time to find the right machine for your business.

Here are some tips on how to buy the right corrugated roll forming machine for your business:

- Determine What Type of Material You Will Be Forming

The first step in choosing the right corrugated roll forming machine is determining what type of material you will be forming. There are several types of materials that can be formed with a corrugated roll former, including plastic sheets, foam boards, cardboard boxes, and even metal sheets. It is important to choose the correct type of material for your specific needs because each has its own unique characteristics that must be taken into account when manufacturing the final product.

- Factor In Machine Size and Capabilities

After determining what type of material you will be formulating, the next step is to factor in the machine’s size and capabilities. The size of the machine will determine how many sheets at a time can processed; while the capabilities of the machine will determine how detailed or intricate the patterns can be created on the finished product. It is important to choose a machine that is able to meet your specific needs.

- Choose the Right Corrugated Roll Forming Machine for Your Business

After determining what type of machine and material you will be using, the final step is to find the right machine for your business. There are a number of different types of corrugated roll forming machine for sale available on the market, so it is important to choose the one that best suits your needs. If you are not sure which machine is right for you, contact a corrugated roll forming specialist or manufacturer for guidance.

Conclusion

In today’s market, it is hard to find a product that can truly stand out. However, if you are in the business of manufacturing corrugated cardboard boxes, then a roll forming machine would be an excellent investment. Not only will this machine save you time and money on production costs, but it will also provide consistent quality control and reduced waste. Considering the benefits of owning a corrugated roll forming machine for sale, should you decide to invest? Let us know what you think in the comments below!

FAQ

What is the difference between forming and rolling?

Thread forming and thread rolling, while both involving the creation of threading, aren’t the same. The primary difference between them is that thread forming is used to create internal threading, whereas thread rolling is used to create external threading.