Struggling to find a roll forming machine & die for your company? If you don’t have time to search for hours on the internet and have no idea where to turn, this article is for you! In this blog, we discuss how to find a reliable manufacturer of roll forming machines, as well as how to get a quote on a custom made machine or die.

What is a Roll Forming Machine & Die?

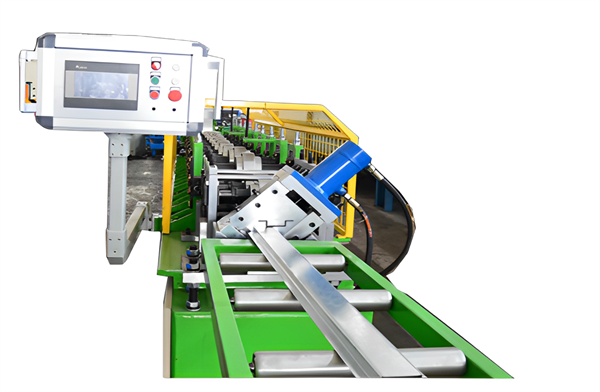

A roll forming machine is a type of machine that is used to create long, flat sheets of metal. The process involves passing the metal sheet through a series of rollers, each of which bends the sheet slightly until it takes on the desired shape.

A die is a tool that is used to cut or shape metal. In the context of roll forming, a die is typically used to cut the metal sheet into individual pieces or to create holes in the sheet.

What are the Benefits of a Roll Forming Machine & Die?

There are many benefits to using a roll forming machine & die. Some of these benefits include:

- Increased production efficiency – When using a roll forming machine, the production process is streamlined and more efficient. This results in increased productivity and less wasted material.

- Greater accuracy – Roll forming machines produce parts with greater accuracy than traditional methods such as stamping or machining. This improved accuracy results in better fitting parts and fewer defects.

- Increased durability – Parts produced with a roll forming machine are often stronger and more durable than those made with other methods. This increased durability can lead to longer lasting products and decreased maintenance costs.

- Flexibility – Roll forming machines can produce parts with a variety of shapes and sizes. This flexibility allows manufacturers to produce parts that meet their specific needs without having to invest in multiple machines or dies.

- Cost savings – In many cases, roll forming can be more cost effective than other methods such as stamping or machining. This cost savings is due to the increased efficiency of the roll forming process as well as the lower tooling costs associated with this method.

How Much Does a Roll Forming Machine & Die Cost?

The cost of a roll forming machine & die varies depending on the type of machine and die needed for your project. For example, a simple hand-operated roll forming machine may cost as little as $500, while a complex, computer-controlled machine can cost tens of thousands of dollars. In addition, the cost of the die itself will vary depending on its size and complexity.

Where Can I Purchase a Roll Forming Machine & Die?

There are a few places that you can purchase a roll forming machine & die. One place is online through a company that specializes in selling these machines. Another place is through a manufacturer that sells the machines as part of their business. Finally, you can also find used roll forming machines and dies through businesses that resell them.

When looking to purchase a roll forming machine and die, it is important to compare prices between different sellers in order to get the best deal. It is also important to make sure that the machine and die you purchase are compatible with each other and will work together properly. Finally, you should also consider the shipping costs associated with the purchase before making your final decision.

-

Double deck roll forming machine

Double deck roll forming machine -

Color steel roll forming machine

Color steel roll forming machine -

Wall panel roll forming machine

Wall panel roll forming machine -

IBR roll forming machine

IBR roll forming machine -

Half round glazed tile roll forming machine

Half round glazed tile roll forming machine -

R panel roll forming machine

R panel roll forming machine -

Automatic roof curving machine

Automatic roof curving machine -

snap clip lock metal roof panel roll forming machine

snap clip lock metal roof panel roll forming machine -

shipping container board panel Roll Forming Machine

shipping container board panel Roll Forming Machine

What are the Different Types of Roll Forming Machine & Die?

There are several different types of roll forming machine & die available on the market. The most common type of machine is the turret punch press, which is used to create a variety of shapes and sizes of metal parts. Other popular types of machines include:

- CNC Machining Centers: These are computer-controlled machines that can create highly accurate and repeatable parts.

- Hydraulic Presses: These machines use high levels of pressure to form metal parts.

- Laser Cutting Machines: These machines use a laser to cut metal parts to specific shapes and sizes.

Conclusion

If you are in the market for a roll forming machine and die, we hope this guide has helped you understand what to look for and how to get the best possible deal. With so many options out there, it can be difficult to know where to start. However, by following our tips and doing your research, you should be able to find the perfect machine for your needs.

FAQ

How is roll forming done?

Roll forming is a unique metal forming process that starts with a long strip of metal, usually in coil form. The roll forming machine forces the material through a series of mated tool dies to achieve a uniform shape. Each step of the operation bends the workpiece little by little until it reaches the desired shape.