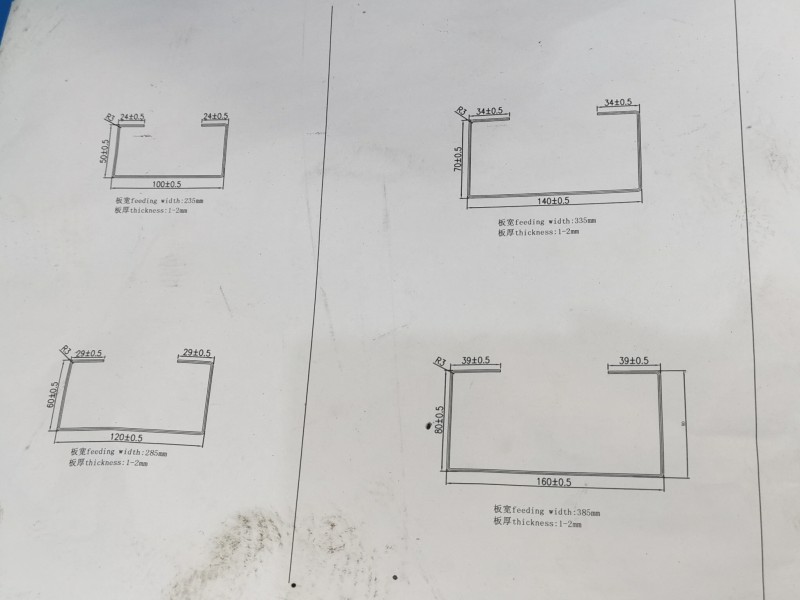

Profile drawing

C Purlin Roll Forming Machine Sizes

- Width: C80-300

- Thickness: 1.5-3.0mm

- Height:40-100mm

C Roll Forming Machine Specifications and Parameter

- The specification of the rolling production (mm): material thickness: 5-3mm; width 80-300mm adjustable any size by motor, height 40-100mm adjustable any size by motor

- The speed of the roll-in: 10M/min

- The number of the roller: 20 Stations

- The material of the roller: use the excellent hammered steel GCr15 to be quenched as a whole, then to process by numerical control.

- The material of the principal axis: use the excellent steel No.45 to process.¢75mm

- The power of the principal electric motor: 11kW cycloid reducer, width, height adjustment motor 3 * 0.75kw

- Hydrodynamic station cut: 7.5KW

- Drive-by-wire system: The whole machine uses the PLC industrial computer to control by frequency conversion.

- The size of the shape equipment: 10.3×1.8×1.4(see the appendix 2)

- The gross weight of the equipment: 10T

- Accessories: one set of the stacking shelf, one set of leveling mechanism, one set of punching and cutting mechanism, one set of hydrodynamic station, one set of computer control system (Panasonic programmable PLC, touchable display screen, a series of Panasonic transducers, and OMRON encoder) a set of material shelf.

- Voltage: 220V, 60hz, 3 phases.

C Roll Forming Machine process

Decoiler——Feeding with leveling—— Punching——— Cutting——— Roll forming—Out table

C Roll Forming Machine List

| No | Name | Quantity |

| 1 | 3T hydraulic Un-coiler | 1 set |

| 2 | Feeding with guide | 1 set |

| 3 | Main roll forming machine | 1 set |

| 4 | Hydraulic punching device | 2 sets |

| 5 | Control box | 1 unit |

| 6 | Hydraulic station | 1 unit |

| 7 | Out tables | 2 units |

| 8 | Spare parts | 1 package |

| 9 | Safety cover | 1 unit |

| 10 | Hydraulic cutting device | 1 unit |

What is c roll forming machine?

A C roll forming machine is a type of industrial machinery used in the manufacturing process of metal profiles with a C-shaped cross-section. Roll forming is a continuous bending operation where a long strip of metal is passed through a series of rollers, each performing a specific bending action. The rollers progressively shape the metal strip into the desired profile.

In the case of a C roll forming machine, the rollers are designed to form the metal strip into a C-shaped profile, which resembles the letter “C” when viewed from the side. The machine typically consists of multiple sets of rollers, each set performing a specific bending action. These rollers are often adjustable to accommodate different widths and thicknesses of metal strips.

The C roll forming machine is commonly used in various industries, including construction, automotive, and manufacturing, to produce C-shaped profiles that are used for structural supports, framing, and other applications. The machine offers high production efficiency, precise shaping, and consistent quality, making it a preferred method for producing large quantities of C-shaped metal profiles.

application of c purlin roll forming machine?

The C purlin roll forming machine is specifically designed for producing C-shaped purlins, which are commonly used in construction and structural engineering applications. Here are some of the main applications of C purlins:

- Roofing Systems: C purlins are often used as roof beams or supports in industrial and commercial buildings. They provide structural stability and support for the roof panels, helping to distribute the weight of the roof evenly.

- Wall Framing: C purlins are used in wall framing applications, especially in metal buildings. They act as vertical supports for the wall panels and help maintain the structural integrity of the building.

- Mezzanine Floors: C purlins are utilized in mezzanine floor constructions to create additional levels or platforms within a building. They provide support for the flooring system and help distribute the load evenly.

- Shelving Systems: C purlins can be used as horizontal supports in shelving and racking systems. They provide the necessary strength and stability to hold heavy loads and organize storage spaces efficiently.

- Agricultural Structures: C purlins find applications in agricultural buildings, such as barns and sheds. They are used for constructing frames and supports for roofing, walls, and equipment storage.

- Solar Panel Installations: C purlins are commonly employed in solar panel mounting systems. They serve as a framework for securing and supporting the solar panels, ensuring proper installation and stability.

The C purlin roll forming machine allows for efficient and precise production of C purlins in various sizes and specifications, meeting the specific requirements of different applications.

advantages of automatic c purlin roll forming machine

Automatic C purlin roll forming machines offer several advantages over manual or semi-automatic methods. Here are some key advantages of using an automatic C purlin roll forming machine:

- High Efficiency: Automatic machines are designed for continuous production, enabling high-speed and efficient manufacturing of C purlins. They can produce a large number of purlins in a shorter time frame compared to manual methods, increasing productivity and reducing production time.

- Consistency and Precision: Automatic machines are programmed to perform precise and consistent bending and forming operations. This ensures that each C purlin produced has uniform dimensions and shapes, meeting the required specifications. The accuracy and consistency of the machine minimize material waste and improve the overall quality of the finished products.

- Versatility and Flexibility: Automatic C purlin roll forming machines can be adjusted and programmed to produce C purlins of various sizes, profiles, and specifications. They offer flexibility in terms of changing production requirements, allowing for quick adjustments to accommodate different project needs.

- Reduced Labor and Operator Skill Requirements: Automatic machines significantly reduce the labor and skill requirements compared to manual or semi-automatic methods. Once the machine is set up and programmed, it can operate with minimal human intervention. This reduces labor costs, minimizes the risk of errors caused by human factors, and eliminates the need for highly skilled operators.

- Improved Safety: Automatic C purlin roll forming machines are equipped with safety features and mechanisms to protect operators and prevent accidents. They typically include safety guards, emergency stop buttons, and sensors that detect abnormalities or obstructions in the production process, ensuring a safer working environment.

- Integration with Production Line: Automatic machines can be integrated into a larger production line or system, allowing for seamless and synchronized production processes. This integration enables efficient material handling, automated feeding of raw materials, and integration with downstream operations such as cutting, punching, and stacking.

Overall, the advantages of automatic C purlin roll forming machines include increased production efficiency, improved product quality, versatility, reduced labor requirements, enhanced safety, and compatibility with larger production systems. These advantages make them a preferred choice for manufacturers in the construction and metalworking industries.

how much of c shape purlin roll forming machine?

The cost of a C shape purlin roll forming machine can vary depending on several factors, including the machine’s specifications, features, brand, and the region or country where it is purchased. Additionally, the cost may also be influenced by the level of automation and complexity of the machine.

Generally, C shape purlin roll forming machines can range in price from a few thousand dollars to several hundred thousand dollars. Smaller, entry-level machines with basic features may be more affordable, while larger, fully automated machines with advanced capabilities and higher production capacities will generally have a higher price tag.

It is essential to consider factors such as the desired production capacity, the level of automation required, and the specific features and specifications needed for your production needs. It is recommended to contact machinery suppliers or manufacturers directly to obtain accurate and up-to-date pricing information based on your specific requirements.

Reviews

There are no reviews yet.