Product Description

– Vigacero Profile Easy Deck Roll Forming Machine is automatic hydraulic shearing machine.

– The production is used for floor panels.The production has high wave, high strength and other characteristics.

– roll forming machine has a high degree automatically producing, and low cost.

– Vigacero Profile Easy Deck Roll Forming Machine is a new type of energy-saving and high-effective producing equipment for steel structure.

The Vigacero profile is a typical profile drawing of South America, popular in Chile, Perú, Ecuador, Colombia, Bolivia it is used as separate joists to support the slabs of the floor slabs, which are supported on the walls, concrete or metal beams.

Vigacero Profile Easy Deck Roll Forming Machine can manufacture with hot rolled carbon steel (black steel) or pre-galvanised steel, with a thickness of 1.5mm. It can produce the profile with or without ribs, with or without grooves or smooth, we can customize the machine depending on your profile.

Main Roll forming machine technique data

- Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel

- Working Speed: 12 meters / min

- Forming Steps: about 24 stations

- Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

- Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

- Driven system: Gear box

- Main Power with reducer: 22KW WH Chinese Famous

- Cutting: Hydraulic Cutting Cr12mov

- Material of Cutting Knife: Cr12Mov, Quench HRC58-62

- Hydraulic Station Power: 4KW Wuxi Wanshen Famous Chinese Brand

- The whole machine is controlled by industry computer-PLC.

- PLC–Panasonic, Japan English and Chinese Language

- Encoder–Omron, Japan

- Electric parts–Schneider

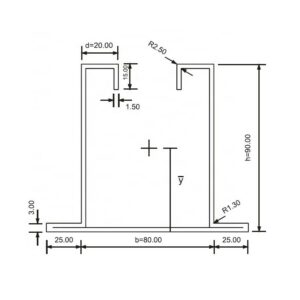

Profile

| S.N | Equipment name | Quantity |

| 1 | 5T hydraulic un-coiler with coil car | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Servo following cutting device | 1 set |

| 4 | Hydraulic station | 1 set |

| 5 | Hydraulic punching with logo | 1 set |

| 6 | Control system ( including control box) | 1 set |

| 7 | 6 meters auto stacker | 1 unit |

| 8 | Spare parts | 1 package |

| 9 | Hydraulic Cutting die | 1 set |

How does deck roll forming machine work?

A deck roll forming machine is used to produce metal deck profiles commonly used in the construction industry for forming the base of floors and roofs. The machine works by continuously feeding a coil of metal through a series of rollers that gradually shape the metal into the desired deck profile.

Here is a step-by-step overview of how a deck roll forming machine typically works:

- Coil feeding: The process begins by feeding a coil of metal, typically steel, into the roll forming machine. The coil is mounted on a motorized decoiler, which unwinds the metal as it passes through the machine.

- Leveling and guiding: The metal strip passes through a set of leveling rolls, which flatten and straighten the material. This ensures that the metal strip is uniform and ready for the roll forming process. Guide rolls are used to properly position the strip as it enters the forming section.

- Pre-punching (optional): Some deck roll forming machines may include a pre-punching station. This station uses specialized punches and dies to create any necessary holes or features in the metal deck profile before it is fully formed. Pre-punching is commonly done to facilitate the installation process.

- Roll forming: The heart of the machine is the series of roll forming stations. These stations consist of multiple sets of rollers, each with a specific shape and position. As the metal strip passes through the stations, the rollers gradually bend and shape the strip into the desired deck profile. The number of stations and the complexity of the roller profiles depend on the specific design requirements of the deck.

- Cutting: Once the metal strip has been fully formed into the deck profile, a cutoff system is activated. This system may employ a flying cutoff or a stationary shear to cut the deck into the desired lengths. The cutoff system is synchronized with the speed of the roll forming machine to ensure precise and accurate cuts.

- Stacking or packaging: After the deck profiles are cut to length, they are typically stacked or packaged for further processing or shipment. The stacking process can be automated using conveyor systems or other material handling equipment.

Throughout the entire process, the machine is typically controlled by a computerized system that allows for precise control of the speed, positioning, and other parameters. This ensures consistent and high-quality production of the metal deck profiles.

what is profile roll forming machine?

A profile roll forming machine, also known as a roll former, is a specialized piece of equipment used in the metalworking industry to shape metal sheets or strips into continuous profiles of various shapes and sizes. It is a continuous bending process where the metal is passed through a series of roller dies that progressively shape it into the desired profile.

Here are the key components and working principles of a profile roll forming machine:

- Frame: The machine consists of a sturdy frame that provides support and stability. It holds all the components together and ensures precise alignment during the forming process.

- Entry section: The metal strip or sheet is fed into the roll forming machine through the entry section. It may include a decoiler or other mechanisms for feeding the material.

- Rollers and roller dies: The heart of the roll forming machine is a series of roller dies. These dies are mounted on multiple forming stations along the length of the machine. Each forming station typically consists of a set of top and bottom rollers, which are designed with specific profiles that gradually shape the metal as it passes through.

- Roll forming process: The metal strip is fed through the first set of rollers, and the initial shaping of the profile begins. As the strip progresses through the machine, it is guided and shaped by the subsequent sets of rollers. Each set of rollers imparts a small incremental change to the metal, gradually forming the desired profile. The number of forming stations and roller sets depends on the complexity of the profile being produced.

- Cutting and punching: Depending on the specific requirements of the profile, the roll forming machine may include cutting and punching stations. These stations are used to cut the profile to the desired length and create holes or other features as needed. The cutting and punching mechanisms are typically synchronized with the speed of the machine to ensure accurate and precise operations.

- Exit section: Once the metal strip has passed through all the forming stations and any cutting/punching stations, it exits the roll forming machine through the exit section. The finished profile can then be further processed, stacked, or packaged as required.

The entire roll forming process is typically controlled by a computerized system that allows for precise control of the roller positions, speed, and other parameters. This ensures consistent and high-quality production of the desired profiles. Roll forming machines are widely used in various industries, including construction, automotive, appliance manufacturing, and more, to produce a wide range of profiles such as C-channels, U-channels, hat sections, and custom shapes.

application of metal deck roll forming machine

The metal deck roll forming machine is widely used in the construction industry for the production of metal deck profiles. These profiles are an integral part of building structures, serving as the base for floors, roofs, and other structural components. Here are some specific applications of metal deck roll forming machines:

- Floor decking: Metal deck profiles produced by roll forming machines are commonly used as floor decking in commercial, industrial, and residential buildings. The metal decks provide a strong and durable base for concrete floors, offering structural support and stability. They are typically installed in multi-story buildings, mezzanine floors, and platforms.

- Roof decking: Metal decks are also used as roof decking in various types of buildings. The profiles produced by roll forming machines provide a reliable substrate for roofing materials such as single-ply membranes, built-up roofing systems, and metal roofing panels. The metal decks contribute to the overall strength, stability, and weatherproofing of the roof structure.

- Composite flooring systems: Metal deck profiles can be combined with concrete to create composite flooring systems. The metal deck acts as a formwork during the concrete pouring process, and after curing, the concrete and metal deck work together as a composite structure. This combination enhances the load-bearing capacity, fire resistance, and acoustic performance of the flooring system.

- Bridge construction: Metal decks produced by roll forming machines are used in the construction of bridges and elevated highways. The profiles serve as bridge decks, providing a stable platform for vehicles and pedestrians. Metal decks are often selected for their high strength-to-weight ratio, corrosion resistance, and ease of installation.

- Retrofitting and renovation: Metal deck roll forming machines are also used in retrofitting and renovation projects. Existing buildings may require strengthening or additional floors, and the metal deck profiles can be used to create new floors or reinforce existing ones. The roll forming machines allow for the production of customized profiles to match specific project requirements.

Overall, the metal deck roll forming machine plays a crucial role in the construction industry by efficiently producing metal deck profiles that are essential for creating sturdy and reliable floors, roofs, and structural elements in buildings and bridges.

Reviews

There are no reviews yet.