Z Purlin Roll Forming Machine Specifications and Parameter

- The specification of the rolling production (mm):0.7mm stainless steel

- The speed of the roll-in: 10-12M/min

- The number of the roller: about 18 stations

- The material of the roller: use the excellent hammered steel GCr15 to be quenched as a whole, then to process by numerical control.

- The material of the principal axis: use the excellent steel No.45 to process.

- The power of the principal electric motor: 7.5kW

- Hydrodynamic station cut: 5.5kW

- Drive-by-wire system: The whole machine uses the PLC industrial computer to control by frequency conversion.

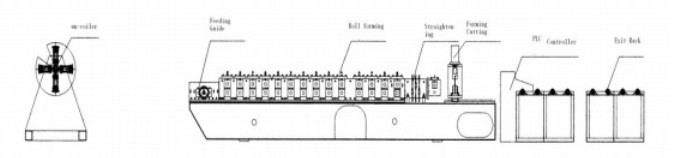

- The size of the shape equipment: 7.3×0.8×1.0 meter (see the appendix 2)

- The gross weight of the equipment: About 4 T

The Working Flow

Uncoiling—Feeding & Leveling—Roll forming—Cutting—Products collecting

Profile Drawing(OEM)

Z Purlin Roll Forming Machine List

| No | Name | Quantity |

| 1 | 3 ton Passive de-coiler | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Control box | 1 unit |

| 4 | Hydraulic station | 1 unit |

| 5 | Out tables | 2 units |

Z Purlin Roll Forming Machine Application

what is z purlin roll forming machine?

A Z purlin roll forming machine is a type of industrial machinery used to manufacture Z-shaped purlins. Purlins are structural elements commonly used in the construction industry to provide support and stability to roofs and walls of buildings. They are typically made of steel and are designed in various shapes, including C, Z, and U profiles.

The Z purlin roll forming machine is specifically designed to produce Z-shaped purlins with consistent dimensions and high precision. The machine takes a coil of steel and passes it through a series of rollers, gradually forming the desired shape. The rollers are strategically designed to bend the steel into the Z profile by applying pressure at specific points.

The machine consists of several components, including a decoiler to hold the steel coil, a leveling device to ensure a flat surface, a punching unit for creating holes or slots, a cutting unit for length adjustment, and a control system to monitor and regulate the machine’s operations.

Once the steel passes through the roll forming process, it is cut into specific lengths and can be further processed or assembled for use in construction projects. Z purlins are widely used in industrial and commercial buildings to provide structural support for roofing systems and to help distribute the load evenly across the building framework.

Overall, the Z purlin roll forming machine plays a crucial role in the efficient and cost-effective production of Z-shaped purlins for construction purposes.

how to choose purlin roll forming machine?

When choosing a purlin roll forming machine, there are several factors to consider to ensure that you select the most suitable machine for your specific needs. Here are some key points to keep in mind:

- Purlin specifications: Determine the specific requirements for your purlins, such as the shape (Z, C, or U), dimensions (width, height, and thickness), and material (typically steel). Make sure the machine you choose can accommodate these specifications.

- Production capacity: Consider the desired production capacity of your purlins. Look for a machine that can meet your production requirements in terms of speed, output, and efficiency. Take into account factors like the number of purlins produced per minute or hour.

- Customization options: If you require flexibility in terms of purlin dimensions or profiles, choose a roll forming machine that offers customization options. This allows you to adjust the machine settings to produce different sizes and shapes of purlins.

- Quality and accuracy: Check the reputation and reliability of the machine manufacturer. Look for machines that are known for their high-quality output, precise forming, and consistent dimensions. Consider reading customer reviews and testimonials to gauge the machine’s performance.

- Durability and maintenance: Ensure that the machine is built to withstand the rigors of continuous operation. Look for machines made from high-quality materials and components. Additionally, consider the maintenance requirements and availability of spare parts to minimize downtime.

- Automation and control: Evaluate the level of automation and control offered by the machine. Advanced features like computer numerical control (CNC) systems can enhance precision, efficiency, and ease of operation. Automation also reduces the need for manual intervention and improves overall productivity.

- After-sales support: Inquire about the manufacturer’s after-sales support, including technical assistance, training, and warranty. A reputable manufacturer should provide comprehensive support and be readily available for any troubleshooting or maintenance needs.

- Cost and budget: Consider the machine’s price in relation to your budget. However, it is essential to strike a balance between cost and quality. Remember that investing in a higher-quality machine upfront can result in long-term cost savings through increased productivity and reduced maintenance.

By considering these factors, you can select a purlin roll forming machine that aligns with your specific requirements, ensuring efficient production of high-quality purlins for your construction projects.

advantages of oem purlin roll forming machine

Opting for an OEM (Original Equipment Manufacturer) purlin roll forming machine offers several advantages. Here are some key benefits of choosing an OEM machine:

- Quality assurance: OEM machines are manufactured by the original equipment manufacturer themselves. This ensures that the machine meets the highest quality standards and specifications set by the manufacturer. OEM machines are built using high-quality materials and components, resulting in a durable and reliable product.

- Performance and efficiency: OEM machines are designed and engineered to deliver optimal performance and efficiency. The manufacturer has extensive knowledge and expertise in roll forming technology, allowing them to design machines that maximize productivity, minimize waste, and provide precise forming of purlins.

- Technical expertise and support: When you purchase an OEM machine, you gain access to the manufacturer’s technical expertise and support. They have in-depth knowledge of the machine’s operation, maintenance, and troubleshooting. This support ensures smooth installation, training, and ongoing assistance, minimizing downtime and optimizing machine performance.

- Customization options: OEM manufacturers often offer customization options to meet specific customer requirements. They can tailor the machine’s design, features, and capabilities according to your needs. This flexibility allows you to produce purlins of various dimensions, shapes, and materials, catering to diverse construction projects.

- Availability of spare parts: OEM manufacturers have a ready supply of genuine spare parts for their machines. This ensures that if any component needs replacement, you can easily obtain the correct parts directly from the manufacturer. Using genuine spare parts enhances machine performance, reliability, and longevity.

- Warranty coverage: OEM machines typically come with warranty coverage, providing assurance and protection against manufacturing defects or performance issues. The warranty varies depending on the manufacturer and machine model. It is advisable to review the warranty terms and conditions before making a purchase.

- Long-term support: OEM manufacturers have a long-term commitment to their products. They continuously invest in research and development, incorporating technological advancements and improvements into their machines. This commitment ensures that you have access to upgrades, software updates, and ongoing support throughout the lifespan of the machine.

- Resale value and market reputation: OEM machines generally hold better resale value due to their recognized brand and reputation in the market. Choosing an OEM machine can provide better long-term value for your investment, as potential buyers often prefer machines from reputable manufacturers.

In summary, selecting an OEM purlin roll forming machine offers quality assurance, performance optimization, technical support, customization options, availability of spare parts, warranty coverage, long-term support, and better resale value. These advantages contribute to a smoother production process, increased efficiency, and overall customer satisfaction.

Reviews

There are no reviews yet.