At some point in your career, you might have had a need for roll forming machines. A machine that can cut, bend and crease metal to be used as parts of pieces of machinery or even fabricating material for your own project. Though many factors contribute to the cost of a roll forming machine, this article outlines some general guidelines on how much they usually cost.

What are Roll Forming Machines Used For?

Roll forming machines are used to create plastic, metal or even composites parts by rolling a stretchable material around a cylindrical or conical die. The process is similar to casting, but with less waste and no need for molds. There are a variety of roll forming machines on the market, from small tabletop models to large industrial machines.

Types of Roll Forming Machines

Roll forming machines come in a variety of shapes and sizes. The most popular types are those with parallel rollers, which are used for creating round objects. There are also machines that use curved rollers, which are better suited for making tubes and other shapes with curves.

Roll forming machines can either be manual or automated. Manual machines require the operator to place the object to be formed on the rollers and then press down on the machine to create the desired shape. Automated machines have a computerized control system that does the labor for you, so you can focus on other tasks.

-

Weld pipe roll forming machine

Weld pipe roll forming machine -

Joint Rack steel beam roll forming machine

Joint Rack steel beam roll forming machine -

Garage door panel roll forming machine

Garage door panel roll forming machine -

Double deck roll forming machine

Double deck roll forming machine -

Color steel roll forming machine

Color steel roll forming machine -

Wall panel roll forming machine

Wall panel roll forming machine -

IBR roll forming machine

IBR roll forming machine -

Half round glazed tile roll forming machine

Half round glazed tile roll forming machine -

R panel roll forming machine

R panel roll forming machine

Cost of a Roll Forming Machine

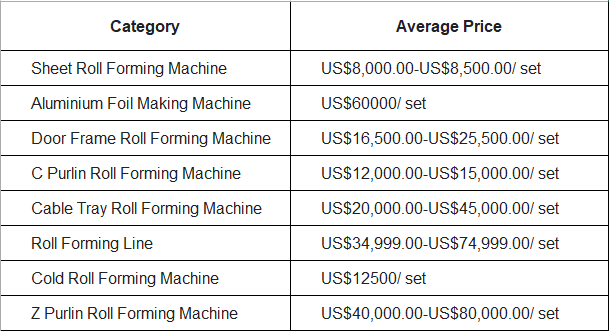

Roll forming machines range in price from around $8,000 to $80,000. The cost of a machine depends on the features and specifications it includes. Most roll forming machines are built to produce small-to-medium size parts.

The most common type of roll forming machine is the vacuum former. Vacuum former machines use high-pressure air to form metal into desired shapes by drawing it tight around the component. Vacuum former machines are popular for producing automotive parts, medical devices and other small-to-medium size parts. They are also commonly used for making prototype parts.

Another common type of roll forming machine is the die press. Die press machines use heat and pressure to form metal into desired shapes. Die press machines are more expensive than vacuum former machines and are more versatile, able to produce large parts as well as small parts. Die press machines range in price from around $5,000 to $50,000.

There is also a variety of rotary die stamping machines available that use a die to stamp out components from a sheet of metal. Rotary die stamp ing machines are less expensive than die press machines, and they can produce parts up to roughly 3/4-inch thick.Rotary die stamping machines are limited by their ability to produce large parts, however. For instance, a rotary die stamping machine cannot produce a part larger than 20 inches in diameter. Die stamping machines are also not as versatile as vacuum former or roll forming machines.

Die stamping machines have the potential of being the most cost effective method for creating precision parts because they allow users to create prototypes quickly in an inexpensive manner. Roll forming and vacuum former machines need long lead times and high staff costs for fabrication processes that utilize few manual steps, such as drilling or cutting.The main disadvantages of rotary die stamping machines include the large amount of time required to change a part, the limitations in the size of parts that can be produced on rotary die stamping machines, and the lack of versatility.

Where to Purchase a Roll Forming Machine

Roll forming machines are popular tools for producing custom parts and products. They can be used in a variety of industries, including automotive, medical, and aerospace.

There are a number of different roll forming machines on the market. It can be difficult to decide which machine is right for your needs. In this article, we will discuss the top 10 best places to purchase a roll forming machine.

- Amazon

- eBay

- The Home Depot

- Menard’s

- Lowes

- Sears

- Walmart

- Ace Hardware

- Meijer

- Kmart