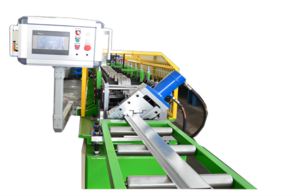

Roof Flashing Roll Forming Machine

what is Roof Flashing Roll Forming Machine?

A Roof Flashing Roll Forming Machine is a type of roll forming machine that is used to produce roof flashing products. Roof flashing is a material used in construction to prevent water from penetrating the roof of a building. The Roof Flashing Roll Forming Machine is used to shape and form metal sheets into the desired shape and size of the roof flashing. The machine works by feeding a flat sheet of metal into a series of rollers that gradually shape the metal into the desired form. The finished product is then cut to the desired length and packaged for shipment. Roof Flashing Roll Forming Machines are commonly used in the construction industry to produce high-quality, cost-effective roof flashing products.

6 roof flashing roll forming machine application

The Roof Flashing Roll Forming Machine is primarily used in the construction industry to produce roof flashing products for residential, commercial, and industrial buildings. The following are some of the common applications of roof flashing products produced by a Roof Flashing Roll Forming Machine:

Roof and wall intersections: Roof flashing is used to seal the intersection between the roof and wall to prevent water from penetrating the building.

Chimneys and vents: Roof flashing is used to seal around chimneys and vents to prevent water from entering the building.

Skylights: Roof flashing is used to seal around skylights to prevent water from entering the building.

Gutters and downspouts: Roof flashing is used to seal the connection between gutters and downspouts to prevent water from penetrating the building.

Roof valleys: Roof flashing is used to seal the valleys of a roof to prevent water from penetrating the building.

Roof penetrations: Roof flashing is used to seal around pipes, ducts, and other roof penetrations to prevent water from entering the building.

The use of a Roof Flashing Roll Forming Machine allows for the production of high-quality, consistent roof flashing products that are essential for ensuring the watertight integrity of buildings.

roof flashing roll forming machine price

The price of a Roof Flashing Roll Forming Machine can vary greatly depending on several factors, such as the size and capacity of the machine, the materials used in its construction, and the complexity of its design. On average, the price of a Roof Flashing Roll Forming Machine can range from several thousand dollars for a basic machine to several hundred thousand dollars for a high-capacity, fully automated machine.

It’s also important to consider the cost of maintenance, training, and replacement parts when evaluating the total cost of a Roof Flashing Roll Forming Machine. Additionally, the cost of the raw materials used to produce roof flashing products should also be taken into consideration when determining the overall cost of the machine.

Ultimately, the best way to determine the price of a Roof Flashing Roll Forming Machine is to get quotes from multiple suppliers and compare the features and benefits of each machine to determine which one offers the best value for your investment.

5 Suhang roof flashing roll forming machine advantages

Suhang-made Roof Flashing Roll Forming Machines have several advantages that make them popular among construction industry professionals, including:

Affordable pricing: Chinese-made Roof Flashing Roll Forming Machines are often more affordable than machines made in other countries, making them a cost-effective solution for many businesses.

High-quality construction: Despite their lower price point, many Chinese-made Roof Flashing Roll Forming Machines are constructed with high-quality materials and feature advanced design and manufacturing techniques, making them durable and reliable.

Wide range of options: Chinese manufacturers offer a wide range of Roof Flashing Roll Forming Machines, from basic models to high-capacity, fully automated machines, allowing customers to choose the machine that best fits their needs and budget.

Strong after-sales support: Many Chinese manufacturers provide strong after-sales support, including training and maintenance services, to help customers get the most out of their machines.

Access to a large market: By sourcing their machines from China, customers can access a large market and take advantage of economies of scale to get the best possible pricing.

However, it’s important to thoroughly research potential suppliers and carefully evaluate the quality and reliability of their machines before making a purchase. Additionally, it may be necessary to have additional support or service arrangements in place, especially if the manufacturer is located in another country.