A roof roll forming machine is a machine that typically uses a conveyor belt and a reciprocating or rotating arm to form steel at high speeds. Roof roll forming machines are used in the production of rolled steel for various building projects, including roofs and decking. This article will explain what roof roll forming machines are and their uses.

Definition

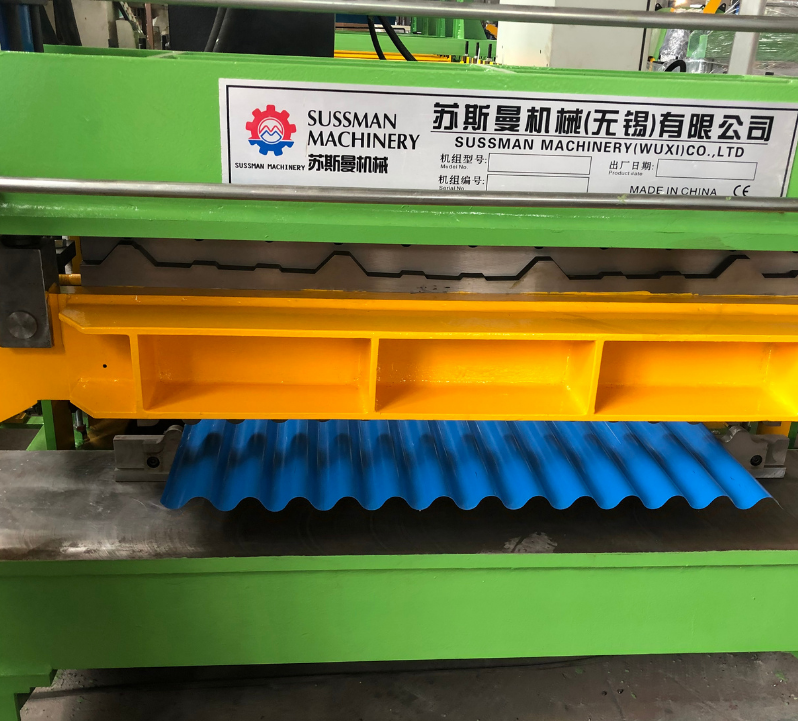

A roof roll forming machine is a type of industrial equipment that is used to form roofing sheets. The machine consists of a series of rollers that deform the roofing sheet into desired shape. It is a large, heavy machine that uses a series of rolls to create a sheet of metal that is the correct thickness and shape.

A roof roll forming machine looks like a roller, but it is shaped more like a tower. Roof rolls are sometimes used in the manufacturing of high-end commercial and industrial roofs.

Types of Roof Roll Forming Machines

There are many different types of roof roll forming machines, but the most common are the horizontal bar type and the pneumatic type. Horizontal bar type machines use a series of horizontal bars to form the roof, while pneumatic type machines use pressurized air to form the roof.

Some other types of roof roll forming machines include the belt type, the cone type, and the screw type. Belt type machines use a series of belts to form the roof, while cone type machines use a cone-shaped head to form the roof. The screw type machines use screws to form the roof.

-

Weld pipe roll forming machine

Weld pipe roll forming machine -

Joint Rack steel beam roll forming machine

Joint Rack steel beam roll forming machine -

Garage door panel roll forming machine

Garage door panel roll forming machine -

Double deck roll forming machine

Double deck roll forming machine -

Color steel roll forming machine

Color steel roll forming machine -

Wall panel roll forming machine

Wall panel roll forming machine -

IBR roll forming machine

IBR roll forming machine -

Half round glazed tile roll forming machine

Half round glazed tile roll forming machine -

R panel roll forming machine

R panel roll forming machine

Uses for a Roof Roll Forming Machine

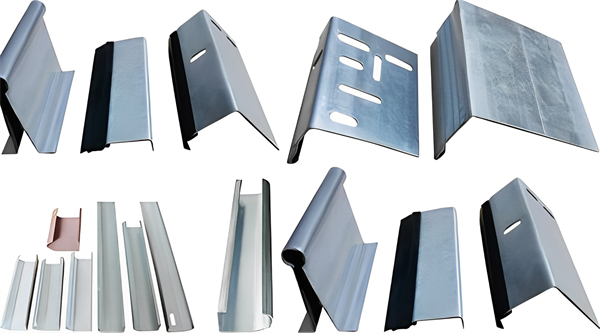

A roof roll forming machine is a versatile tool that can be used for a variety of purposes. Below are just a few examples of what you can do with one:

-Make roof rolls for tiles, or other roofing materials

-Form metal sheets into panels or rounds

-Make plastic parts such as door handles, dashboards, and fenders

-Makenamic items such as sculptures or models

Working Process of Roof Roll Forming Machine

A roof roll forming machine is a machine used to form roof rolls from sheets of metal. Roof roll forming machines use a long, continuous strip of metal to form the roof rolls. The strip is passed through the machine, which curves and folds it into the desired shape. The process is completed by cutting the roof roll from the strip.Some general information about the working process of a roof roll forming machine is outlined below.

1. The feeder mechanism is designed to guide sheets of insulation material into the die area where they are automatically rolled into a desired shape.

2. After the insulation rolls have been formed, they are cut to the correct length and then trimmed to the required width.

3. The finished insulation sheets are then ejected from the die area and moved to a cutting area where they are cut into shaped pieces or strips.

Benefits of a Roof Roll Forming Machine

A roof roll forming machine is a valuable tool that can help with the production of roofing products. It’s an automated machine that helps with the production of roofing forms, which is a key part of the manufacturing process for roofing products. Here are some of the benefits of using a roof roll forming machine:

-It can help increase productivity.

-It can help reduce labor costs.

-It can help reduce manufacturing time.

-It can help reduce errors.

-It can help improve quality.

Conclusion

If you’re in the roofing or construction industry and need to form a roof roll quickly and easily, then a roof roll forming machine is just what you need. These machines use hydraulic pressure to create rolls of insulation, tile, or other materials that are required for roofs and other construction projects. They are an important part of the roofing process and can save you time and money by ensuring that your Roof Roll Forming Machine is properly maintained.