Roofing Roll Forming Machines are a relatively inexpensive and effective way to create durable and long lasting roof tiles. If you are looking for the best machine, then this article will help you decide which one to purchase based on your needs and preferences.

What is a Roofing Roll Forming Machine?

A roofing roll forming machine is a specialized piece of equipment that is used to form roofing rolls. These rolls are used to create roofing tiles, shingles, or other roofing products.

There are a number of different types of roofing roll forming machines available on the market. Some of the more common machines include the batten press and the hot-rolled coil machine. Which one is best for you will depend on your specific needs and preferences.

Benefits of using a Roofing Roll Forming Machine

A roofing roll forming machine is a great way to improve the quality of your roofing job. Here are some of the benefits:

- It can produce high-quality rolls quickly and easily.

- You can get consistent results every time you use it.

- It’s easy to operate, so you won’t have to waste any time getting started.

- It’s safe and easy to use, so you won’t have to worry about damaging your equipment or yourself.

Which Roofing Roll Forming Machine is the Best?

When it comes to roofing roll forming machines, there are a few things you need to consider. The machine’s dimensions, the number of rolls it can make per minute, and its weight are just a few factors. Here are three of the best roofing roll forming machines on the market today:

- ABB Roto Roller SL-2000 – The ABB Roto Roller SL-2000 is an industrial-grade roofing roll forming machine that can make up to 2,000 rolls per minute. It has a dimension of 82″ x 54″ x 83″, making it perfect for large projects.

- CMT Roofing Roll Forming Machine – The CMT Roofing Roll Forming Machine is a smaller option than some of the other machines on this list, but it still boasts some impressive features. It can make up to 1,200 rolls per minute and has dimensions of 63″ x 36″ x 78″.

- Atlas Copco ROF 2000 – The Atlas Copco ROF 2000 is another top pick for those looking for a heavy-duty machine that can handle large projects quickly. It can produce up to 2,000 rolls per minute and has dimensions of 84″ x 45″ x 98″.

-

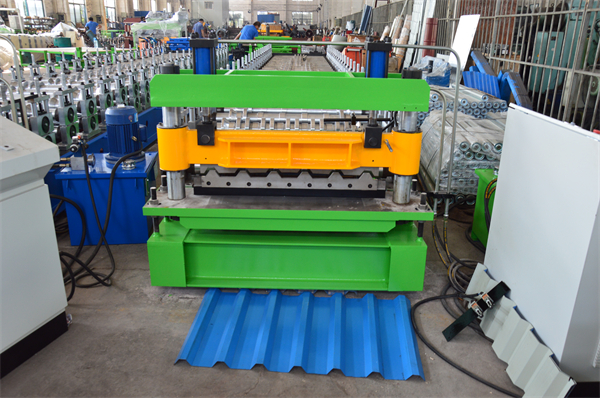

Double deck roll forming machine

Double deck roll forming machine -

Color steel roll forming machine

Color steel roll forming machine -

Wall panel roll forming machine

Wall panel roll forming machine -

IBR roll forming machine

IBR roll forming machine -

Half round glazed tile roll forming machine

Half round glazed tile roll forming machine -

R panel roll forming machine

R panel roll forming machine -

Automatic roof curving machine

Automatic roof curving machine -

snap clip lock metal roof panel roll forming machine

snap clip lock metal roof panel roll forming machine -

shipping container board panel Roll Forming Machine

shipping container board panel Roll Forming Machine

Types of Roofing Roll Forming Machines

There are a few different types of roofing roll forming machines on the market, so it’s important to choose the one that best suits your needs. Here are three of the most common types of roofing roll forming machines:

- CNC Roll forming Machines: These machines use computer control to produce precise, custom-shaped roofing rolls. They’re ideal for large-scale projects, as they can handle large amounts of material quickly and easily.

- Sheet Metal Forming Machines: These machines use metal plates to form roofing rolls. They’re good for smaller projects or those that require fewer rolls than a CNC roll forming machine.

- Manual Roll formers: These machines use human hands to form roofing rolls. They’re slower than other types of roll forming machines, but they’re cheaper and easier to operate.

Factors to consider when shopping for a roll forming machine

There are many different types of roll forming machines on the market, and it can be hard to decide which one is the best for you. Here are some of the factors that you should consider when shopping for a roll forming machine:

- Size. You’ll need to consider how large of a machine you need before making your purchase. Some machines are small enough to fit in a small garage, while others require a larger space.

- Speed. The speed of the roll forming machine is important because it will affect how quickly you can create your rolls. Some machines have multiple speeds, while others have just one speed.

- Type of material you want to form your rolls out of. Rolling machines come in two types: die-casting and molding. Die-casting machines use pressure to create metal sheets, while molding machines use heat and pressure to shape the metal into a desired shape.

- Cost of materials and installation services associated with the machine. Finally, keep in mind the cost of materials and installation services associated with the machine before making your purchase decision.”

Conclusion

Choosing the best roofing roll forming machine can be a daunting task. There are so many options on the market, and each one has its own unique features that could make it the perfect choice for your business. To help you make an informed decision, we’ve outlined some of the key factors to consider when choosing a roofing roll forming machine. Hopefully, this article has helped you narrow down your selection and provided you with all the information you need to decide which machine is right for your needs. Thanks for reading!

FAQ

How is roll forming done?

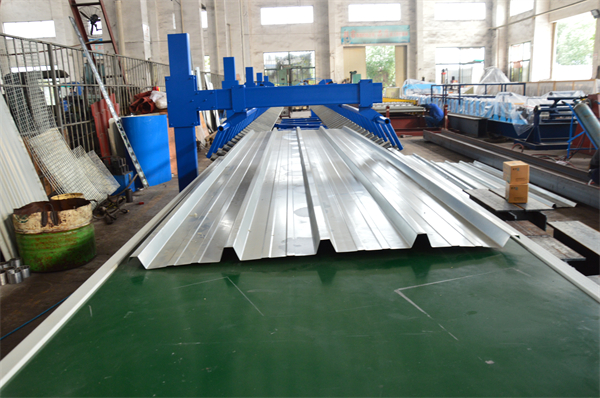

Roll forming is a unique metal forming process that starts with a long strip of metal, usually in coil form. The roll forming machine forces the material through a series of mated tool dies to achieve a uniform shape. Each step of the operation bends the workpiece little by little until it reaches the desired shape.