If you’re looking to buy a steel roll forming machine, here are three models that are best suited for your needs. These machines have many benefits given their different strengths and weaknesses, so use this article to help figure out which type of machine will work best for your business.

What is a steel roll forming machine?

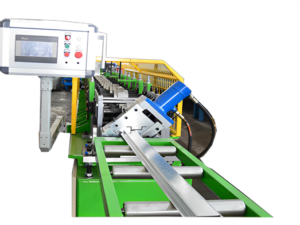

A steel roll forming machine is a crucial piece of equipment for businesses that produce industrial parts. It allows for the accurate and repeatable production of complex shapes from metal sheets, plates, or bars. This machine can also be used to create components for cars, airplanes, and other large-scale manufactured products.

The 3 best steel roll forming machines for your business

Looking for the perfect steel roll forming machine for your business? Here are three of the best options:

- CR-10P Vertical Roll Forming Machine from CR-Tech

This CR-10P vertical roll forming machine is ideal for businesses that require high quality, precision steel rolls. It features a durable construction and can form steel sheets up to 10 feet wide and 6 feet long. Plus, its automatic feeding system ensures accurate production every time.

- JETSTREAM RTZ 900 Forged Roll Forming Machine

If you need a tool that can form large steel rolls quickly and easily, the JETSTREAM RTZ 900 Forged Roll Forming Machine is perfect for you. This machine can form steel sheets up to 9 ft wide and 12 ft long, making it an ideal solution for businesses with complex manufacturing needs.

- CNC Steel form Machinery GX-260R Horizontal Roll Forming Machine

If you’re looking for a low-cost option that still offers high quality output, the CNC Steel form Machinery GX-260R Horizontal Roll Forming Machine may be the perfect choice for you. This machine can form steel sheets up to 260 in diameter and 183 in length, making it an affordable option that’s sure to meet your needs.

How to Choose the Best Steel Roll Forming Machines for Your Business?

There are many things to consider when choosing the best steel roll forming machines for your business. The main factors you’ll need to consider include how much material you can process per hour, the type of steel you want to form, and the size of the finished product.

To determine how much material you can process per hour, you’ll need to know the weight and diameter of the metal sheets you want to form. You can then use a calculator or chart to determine how many sheets of that size can fit on a machine in one hour.

The type of steel you’ll be using will also affect your decision. Thin sheet metal can usually be formed more easily than thick sheet metal because the thinner metal has less resistance when being rolled into a tube or shape. However, thicker metal may require more time and effort to form into a desired shape.

Finally, you’ll need to consider the size of the finished product. For example, if you’re making small parts that will be mounted on a machine or used as part of another product, it might be easier to make them in smaller sizes rather than larger sizes. Larger products may require more expensive equipment and be more difficult to handle, but they may also have greater market potential.

-

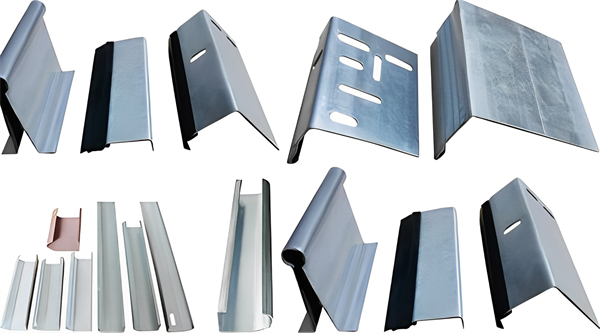

Wall Angle Roll Forming Machine

Wall Angle Roll Forming Machine -

T Bar Roll Forming Machine

T Bar Roll Forming Machine -

C Roll Forming Machine

C Roll Forming Machine -

Z Purlin Roll Forming Machine

Z Purlin Roll Forming Machine -

M Purlin Roll Forming Machine

M Purlin Roll Forming Machine -

Omega roof batten Top hat channel roll forming machine

Omega roof batten Top hat channel roll forming machine -

Metal Keel Drywall stud track roll forming machineRated 5.00 out of 5 based on 1 customer rating

Metal Keel Drywall stud track roll forming machineRated 5.00 out of 5 based on 1 customer rating -

Scaffolding Planks Roll Forming Machine

Scaffolding Planks Roll Forming Machine -

Metal steel structure deck floor deck roll forming machine

Metal steel structure deck floor deck roll forming machine

Types of Steel Roll Forming Machines

There are a few different types of steel roll forming machines on the market, each with its own set of benefits and drawbacks. Below, we’ll take a look at three of the most popular options and help you decide which is right for your business.

- CNC Roll Forming Machines

CNC roll forming machines are by far the most popular option on the market. They offer high-quality results and are capable of producing extremely intricate shapes and patterns in steel. However, they can be quite expensive to buy outright, and require a lot of up-front investment in terms of software and hardware. Additionally, CNC roll forming machines tend to be less versatile than other options, meaning that you may need to invest in additional equipment if you want to produce more complex shapes or patterns.

- Manual Roll Forming Machines

Manual roll formers are a bit cheaper than CNC roll formers, but they don’t offer the same level of customization or precision. They’re also less efficient than CNC machines; as a result, manual roll formers usually require more work per unit of material produced than CNC machines do. Finally, manual roll formers tend to be less reliable than CNC machines – if something goes wrong with them, it can be difficult to fix.

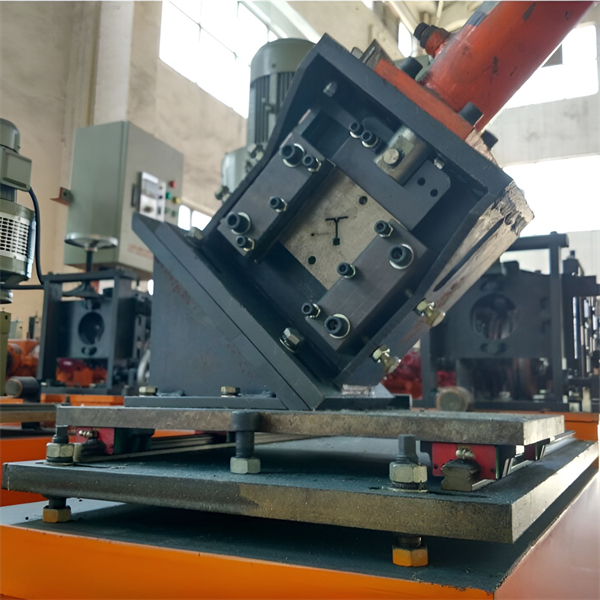

- Hydraulic Roll Forming Machines

Hydraulic roll formers are unique in that they use pressure instead of mechanics to produce metal parts. This makes them incredibly versatile – they can be used to produce almost any shape or pattern, regardless of complexity. Additionally, hydraulic roll formers are relatively easy to operate and maintain, making them a good option for smaller businesses that don’t have the resources or expertise to operate a CNC machine. However, they’re also the most expensive option on the market, and they can be difficult to learn how to use.

Conclusion

If you’re in business, then you know that a reliable, high-performance steel roll forming machine is essential for your success. In this article, we’ve compiled the three best steel roll forming machines on the market and outlined their key features so that you can make an informed decision as to which one is right for your business. Thanks for reading!

FAQ

What Is Rolled Metal Roofing?

Cold rolled steel is hot rolled pickled carbon steel that has been cold reduced and annealed. For roofing, cold rolled steel is a bit easier to form than A606 and produces a similar rustic, non-reflective appearance.