Rolling shutters, also known as roller shutters, are ubiquitous in everyday life. They secure shopfronts, safeguard windows, and function as garage doors. But have you ever wondered how these ubiquitous security barriers are produced? The answer lies in the rolling shutter making machine, a complex yet fascinating piece of industrial equipment.

This comprehensive guide delves into the world of rolling shutter making machines, exploring their components, operation, applications, and considerations for potential buyers.

The Basic Components of a Rolling Shutter Making Machine

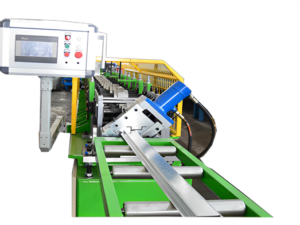

A rolling shutter making machine is an intricate system comprised of several key components, each playing a crucial role in the manufacturing process. Here’s a breakdown of the essential elements:

- Decoiler: This motorized unit feeds the raw metal coil, typically made of steel or aluminum, into the forming process.

- Roll forming station: The heart of the machine, this station consists of a series of precisely shaped rollers that progressively bend and shape the metal coil into the desired profile for the shutter slats.

- Punching and cutting unit: This section incorporates punches and dies to create perforations or cutouts in the formed slats for ventilation or aesthetics.

- Curling unit: As the name suggests, this unit bends the edges of the formed slats inwards, adding rigidity and enhancing the finished look.

- Stacker: This automated system carefully stacks the completed shutter slats, ensuring they are ready for assembly or further processing.

- Control panel: The control panel acts as the brain of the operation, allowing the user to program various parameters like forming profiles, cutting lengths, and production speed.

Operation Mode of a Rolling Shutter Making Machine

Understanding the operational process of a rolling shutter making machine sheds light on its remarkable capabilities. Here’s a simplified breakdown of the steps involved:

- Coil loading: The operator loads the desired metal coil onto the decoiler, ensuring it is properly secured and aligned.

- Metal feeding: The decoiler unwinds the metal coil, feeding it continuously into the roll forming station.

- Profile forming: The metal strip passes through a series of rollers in the roll forming station, each progressively shaping the metal into the specific profile required for the shutter slats. This profile dictates factors like slat strength, insulation properties, and overall aesthetics.

- Punching and cutting: If necessary, the punching and cutting unit creates perforations or specific shapes in the formed slats, catering to ventilation needs or design requirements.

- Curling: The edges of the formed slats are then curled inwards by the curling unit, adding rigidity and improving the overall finish of the slats.

- Stacking: The completed slats are automatically stacked by the stacker, ready for further processing like painting or assembly into a complete rolling shutter.

- Control and monitoring: Throughout the process, the control panel allows the operator to monitor and adjust various parameters, ensuring consistent and efficient production.

-

Joint Rack steel beam roll forming machine

Joint Rack steel beam roll forming machine -

Garage door panel roll forming machine

Garage door panel roll forming machine -

Double deck roll forming machine

Double deck roll forming machine -

channel type trunking cable tray machine

channel type trunking cable tray machine -

Omega roof batten Top hat channel roll forming machine

Omega roof batten Top hat channel roll forming machine -

V Strut Roll Forming Machine

V Strut Roll Forming Machine -

Fire Damper Blade Roll Forming Machine

Fire Damper Blade Roll Forming Machine -

Appliance Bracket C Strut Roll Forming Machine

Appliance Bracket C Strut Roll Forming Machine -

High speed PPGI corrugated sheet roll forming machine

High speed PPGI corrugated sheet roll forming machine

Rolling Shutter Making Machine Applications

The versatility of rolling shutter making machines lies in their ability to manufacture various types of roller blinds, catering to a broad spectrum of applications. Here are some notable examples:

- Security shutters: These robust shutters provide a high level of security for shops, warehouses, and other commercial spaces.

- Fire shutters: Engineered to withstand high temperatures, fire shutters offer crucial fire protection for buildings.

- Hurricane shutters: Designed to resist strong winds and flying debris, hurricane shutters safeguard homes and businesses in regions prone to hurricanes.

- Insulated shutters: These shutters incorporate insulating materials, enhancing thermal efficiency and reducing energy costs.

- Perforated shutters: Offering ventilation while maintaining security, perforated shutters are ideal for areas requiring airflow, such as garages or workshops.

Beyond these common applications, rolling shutter making machines can also be used to produce specialized slats for unique requirements, showcasing the machine’s adaptability and diverse functionality.

Selecting the Right Rolling Shutter Making Machine: Key Considerations

Choosing the ideal rolling shutter making machine requires careful consideration of several factors to ensure it aligns with your specific needs and budget. Here are some key aspects to ponder:

- Production capacity: Evaluate your anticipated production volume to determine a machine capable of meeting your output demands efficiently.

- Slat profiles: Consider the variety of slat profiles you aim to produce, as different machines may specialize in specific profiles or offer wider versatility.

- Material compatibility: Ensure the machine is compatible with the desired materials you intend to use, such as steel, aluminum, or even insulated composite materials.

- Automation level: Determine the level of automation desired, as some machines offer semi-automatic operation requiring manual intervention, while others are fully automated for higher efficiency.

- Safety features: Prioritize machines equipped with essential safety features like emergency stops and guards to protect operators during operation.

- Brand reputation and warranty: Opt for machines from reputable brands known for their quality and reliable after-sales support, including warranty coverage for parts and service.

- Price and budget: While cost is a crucial factor, prioritize finding a machine that offers a balance between affordability and the necessary features to meet your production needs and quality standards.

FAQs

In addition to the information above, here are some frequently asked questions (FAQs) regarding rolling shutter making machines, presented in a table format for clarity:

| Question | Answer |

|---|---|

| What is the typical cost of a rolling shutter making machine? | The price of a rolling shutter making machine can vary significantly depending on factors like brand, capacity, automation level, and additional features. Prices can range from around $5,000 for basic manual machines to over $100,000 for highly automated and versatile models. |

| What are the ongoing maintenance requirements for a rolling shutter making machine? | Regular maintenance is crucial to ensure the smooth operation and longevity of your machine. This typically involves cleaning, lubricating moving parts, and replacing worn-out components as needed. Refer to the manufacturer’s instructions for specific maintenance guidelines. |

| Can I use a rolling shutter making machine to produce slats for DIY projects? | While technically possible, it may not be the most practical or cost-effective solution for small-scale DIY projects. These machines are typically geared towards commercial production, and the initial investment might be high for occasional use. Consider alternative options like purchasing pre-made slats or exploring smaller, more affordable machines specifically designed for hobbyists. |

| Where can I find reputable suppliers of rolling shutter making machines? | Numerous online resources and industrial machinery directories can connect you with reputable suppliers of rolling shutter making machines. It’s advisable to research different manufacturers, compare specifications and pricing, and potentially contact suppliers directly to discuss your specific needs and obtain quotes. |

Conclusion

Investing in a rolling shutter making machine can be a strategic decision for manufacturers looking to expand their product offerings, cater to diverse customer needs, and potentially increase profitability. By carefully evaluating your requirements, prioritizing quality and reliable features, and considering the long-term operational costs and environmental impact, you can make an informed choice that propels your business forward.