Steel roll forming machines are more than just mere tools for manufacturers. Roll formers are used in a variety of industries by machine shops, manufacturers, foundries and fabricators to create everything from furniture to metal parts. In the article below, we will explore some of the most common uses for steel roll forming machines as well as the different types that are available.

What is a Steel Roll Forming Machine?

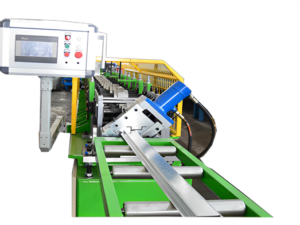

A steel roll forming machine is a type of machinery used to change the shape of a workpiece as it passes through a set of rolls. The machine typically consists of a frame, a set of rolls, and hydraulic or motorized drives that rotate the rolls.

The frame supports the rolls and usually has some means of moving the workpiece through the machine, such as conveyors or chains. The Rolls may be supported on bearings so they can rotate freely, or they may be driven by motors.

Roll forming machines are used to create parts with a variety of shapes and sizes. The most common application for steel roll forming machines is creating panels for roofing or siding. These machines can also be used to create pipe, tubing, structural framing, and more.

How Does a Steel Roll Forming Machine Work?

When it comes to how a steel roll forming machine works, there are a few key things to know. First, these machines take large coils of steel and fed them through a series of rollers, which shapes the steel into the desired profile. Next, the formed steel is cut to length and then sent off to the customer.

In terms of the actual process, it starts with the coil of steel being fed into the machine. The first set of rollers will shape the steel into its basic profile. From there, additional rollers will refine the shape until it matches the desired specifications. Once the steel has been shaped, it will be cut to length and then ejected from the machine.

The whole process is relatively quick and efficient, which is why steel roll forming machines are so popular in a variety of industries. They’re able to produce high-quality parts at a rapid pace, which helps keep costs down for everyone involved.

Types of Steel Roll Forming Machines

There are four main types of steel roll forming machines:

- Cold roll forming machine: Cold roll forming is a process where the steel is Roll Formed at room temperature. Cold roll forming machines are used to create a variety of shapes and sizes out of cold rolled steel.

- Hot roll forming machine: Hot roll forming is a process where the steel is Roll Formed at high temperatures. Hot roll forming machines are used to create a variety of shapes and sizes out of hot rolled steel.

- Combination roll forming machine: Combination roll forming machines are used to create both cold rolled and hot rolled steel products. These machines are able to switch between the two processes, depending on what type of product is being created.

- Custom roll forming machine: Custom roll forming machines are built to specific customer requirements. These machines can be designed to create any shape or size out of either cold rolled or hot rolled steel.

Pros and Cons of Steel Roll Forming Machines

When it comes to steel roll forming machines, there are both pros and cons that need to be considered. On the plus side, these machines can produce a very precise and accurate product. They are also relatively fast, so production can be increased without having to worry about quality control issues. Additionally, steel roll forming machines are very versatile and can be used to create a variety of different products.

On the downside, steel roll forming machines can be expensive to purchase and maintain. They also require a high level of skill to operate, so training may be necessary for your staff. Additionally, because they rely on steel rolls, there is always the potential for breakage or damage which could lead to production delays.

-

Wall Angle Roll Forming Machine

Wall Angle Roll Forming Machine -

T Bar Roll Forming Machine

T Bar Roll Forming Machine -

C Roll Forming Machine

C Roll Forming Machine -

Z Purlin Roll Forming Machine

Z Purlin Roll Forming Machine -

M Purlin Roll Forming Machine

M Purlin Roll Forming Machine -

Omega roof batten Top hat channel roll forming machine

Omega roof batten Top hat channel roll forming machine -

Metal Keel Drywall stud track roll forming machineRated 5.00 out of 5 based on 1 customer rating

Metal Keel Drywall stud track roll forming machineRated 5.00 out of 5 based on 1 customer rating -

Scaffolding Planks Roll Forming Machine

Scaffolding Planks Roll Forming Machine -

Metal steel structure deck floor deck roll forming machine

Metal steel structure deck floor deck roll forming machine

What Is the Future of Steel Roll Forming Machines?

As the steel industry continues to grow, so does the demand for steel roll forming machines. These machines are used to create various types of steel products, such as beams, columns, pipes, and tubing. With the help of these machines, manufacturers can produce steel products that are stronger and more durable than ever before.

As the demand for steel products increases, so does the need for reliable and efficient steel roll forming machines. In order to meet this demand, manufacturers are constantly innovating and improving their machines. The future of steel roll forming machines is very bright, and they will continue to play a vital role in the steel industry.

Conclusion

Steel roll forming machines are an essential piece of equipment for any business that produces steel products. By understanding what they are and how they work, you can make sure that your business is using them to their full potential. If you’re looking for a reliable and efficient way to produce steel products, investing in a steel roll forming machine is a great option.

FAQ

Can stainless steel be roll formed?

Virtually any Stainless Steel or Aluminum that can be formed in sheet-form can also be Roll Formed. Roll Forming is an ideal process when producing long lengths of metal or large quantities.