Cold Roll Forming Machine is an essential machine in fabricating the cold-rolled steel sheets. Cold Roll Forming Machine is a pressure-transmitting machine which can form metal sheets into desired shapes by means of cutting and pressing, without involving any heat treatment.

What is cold roll forming machine?

A cold roll forming machine is a piece of industrial equipment used to form metal into shapes and parts. Cold roll forming is a process that involves passing metal through a series of rollers, each set at a different temperature, to achieve the desired shape. The metal is first passed through a series of warm rollers to soften it, and then through colder rollers to harden it and give it the desired shape.

Cold roll forming machines can be used to create a variety of shapes and parts, including beams, joists, studs, channels, tubing, and more. They are commonly used in the construction and automotive industries.

Types of cold roll forming machines

There are four main types of cold roll forming machines:

- Single-stand machines: These machines have one set of rolls and are used for simple shapes that do not require complex die designs.

- Multi-stand machines: These machines have multiple sets of rolls and are used for more complex shapes that require more precise die designs.

- Continuous machines: These machines have a continuous supply of material and can produce long lengths of product.

- Transfer machines: These machines transfer the product from one station to another, allowing for different operations to be performed on the product at each station.

Pros and Cons of a cold roll forming machine

A cold roll forming machine is a type of rolling mill that is used to form materials at room temperature. The material is passed through a set of rolls to form the desired shape. The main advantage of using a cold roll forming machine is that it can produce complex shapes with very little waste. Additionally, the process is very efficient and can be completed in a short amount of time.

However, there are some disadvantages to using this type of machine as well. One downside is that the quality of the finished product may not be as high as if it were made with a hot roll forming machine. Additionally, the process can be quite noisy and produce dust and fumes, which can be dangerous if not properly ventilated.

What Are the Parts of a Cold Roll Forming Machine?

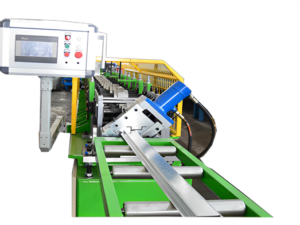

A cold roll forming machine typically consists of a decoiler, a feeding table, a main roll former, cut-off device, and run-out table.

The decoiler is used to uncoil the steel coils and feed the steel strip into the roll forming machine. The feeding table is used to level the strip before it enters the main roll former. The main roll former consists of a series of rolls that form the strip into the desired shape. The cut-off device is used to cut the formed strip to length. The run-out table is used to support the formed strip as it exits the machine.

How Does a Cold Roll Forming Machine Work?

A cold roll forming machine is a machine that forms metal sheets by passing them through rollers at a temperature below the metal’s recrystallization point. This process is used to create parts with a variety of shapes and sizes.

The first step in operating a cold roll forming machine is to load the metal sheets onto the machine. The sheets are then fed through a series of rollers, each of which bends the sheet slightly. The amount of bending can be controlled by adjusting the pressure and speed of the rollers.

Once the desired shape has been achieved, the sheet is cut to length and ejected from the machine. Cold roll forming machines can produce parts with very tight tolerances, making them ideal for use in applications where precision is critical.

-

Wall Angle Roll Forming Machine

Wall Angle Roll Forming Machine -

T Bar Roll Forming Machine

T Bar Roll Forming Machine -

C Roll Forming Machine

C Roll Forming Machine -

Z Purlin Roll Forming Machine

Z Purlin Roll Forming Machine -

M Purlin Roll Forming Machine

M Purlin Roll Forming Machine -

Omega roof batten Top hat channel roll forming machine

Omega roof batten Top hat channel roll forming machine -

Metal Keel Drywall stud track roll forming machineRated 5.00 out of 5 based on 1 customer rating

Metal Keel Drywall stud track roll forming machineRated 5.00 out of 5 based on 1 customer rating -

Scaffolding Planks Roll Forming Machine

Scaffolding Planks Roll Forming Machine -

Metal steel structure deck floor deck roll forming machine

Metal steel structure deck floor deck roll forming machine

The Benefits of a Cold Roll Forming Machine

A cold roll forming machine can offer many benefits for your business. For one, it can help you produce a higher quality product. Additionally, it can increase your production efficiency and decrease your production costs.

When you use a cold roll forming machine, the quality of your product will be much better than if you were to use a traditional manufacturing process. This is because the machine forms the metal at a much lower temperature, which prevents the formation of impurities. Additionally, the machine can apply more pressure to the metal, which results in a stronger and more durable product.

Additionally, a cold roll forming machine can help you save money on your production costs. The machine is able to quickly and easily form the metal into the desired shape, which reduces the amount of time and labor required for traditional manufacturing processes. As a result, you’ll be able to produce more products in less time, which will save you money in the long run.

Conclusion

A cold roll forming machine is a versatile tool that can be used to create a variety of metal products. In this article, we’ve explained how a cold roll forming machine works and some of the benefits of using one. If you’re looking for a way to streamline your metal fabrication process, investing in a cold roll forming machine is a great option.

FAQ

What are the advantages of cold roll forming for gear manufacturing?

It allows for better surface finishes than hot forming, but temperature control is difficult. More complex geometries are possible than with cold forming, but precision is not as high. Because no heat is added to material, cold forming allows for high precision, high quality surface finishes, and high speed production.